Solid and liquid filling intelligent production equipment

An intelligent production, liquid technology, applied in liquid bottling, liquid processing, packaging and other directions, can solve the problem of inconvenient use of bottle caps, achieve the effect of easy opening, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

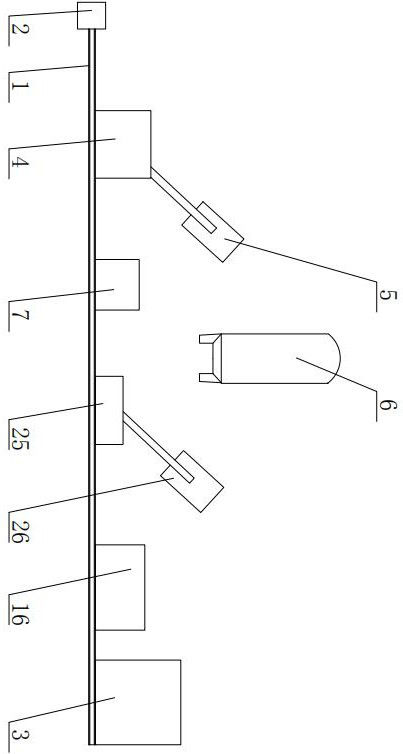

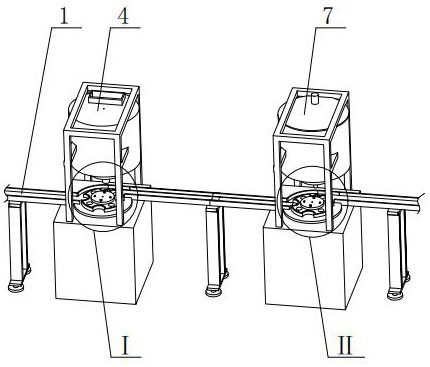

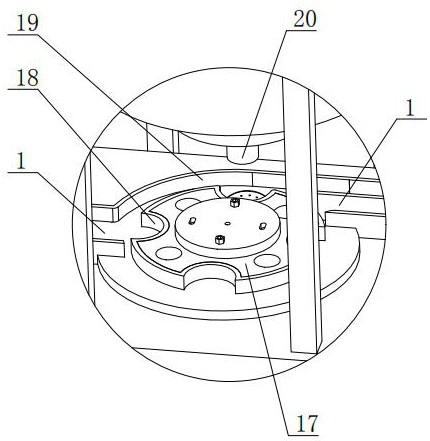

[0023] An intelligent production equipment for solid liquid filling, including a conveying line 1, and also includes a bottle loading platform 2, a solid filling mechanism, a liquid filling mechanism, a sealing mechanism, a labeling mechanism 16 and a packing platform arranged in sequence along the conveying line 1 3. The bottle loading table 2 is used to transport bottles to the conveying line 1, the solid filling mechanism is used to fill the bottles on the conveying line 1 with garlic, the liquid filling mechanism is used to fill the bottles with sweet and sour solution, and the seal is sealed. The mechanism is used to fix the bottle cap on the bottle to form a sealed bottle, the labeling mechanism 16 is used to paste a label on the sealed bottle, and the packing platform 3 is used to pack the sealed bottle with the label attached.

[0024] The conveying line 1 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com