Concrete-filled steel structural support columns

A steel structure and support column technology, applied in the field of steel structure support columns, can solve problems affecting structural strength, etc., and achieve the effects of ensuring structural strength, reducing the number of cavities, and slowing down the falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

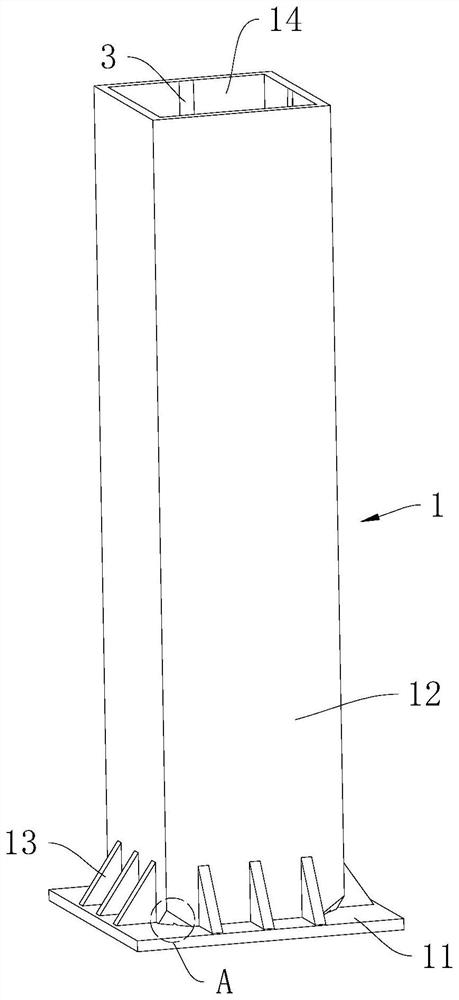

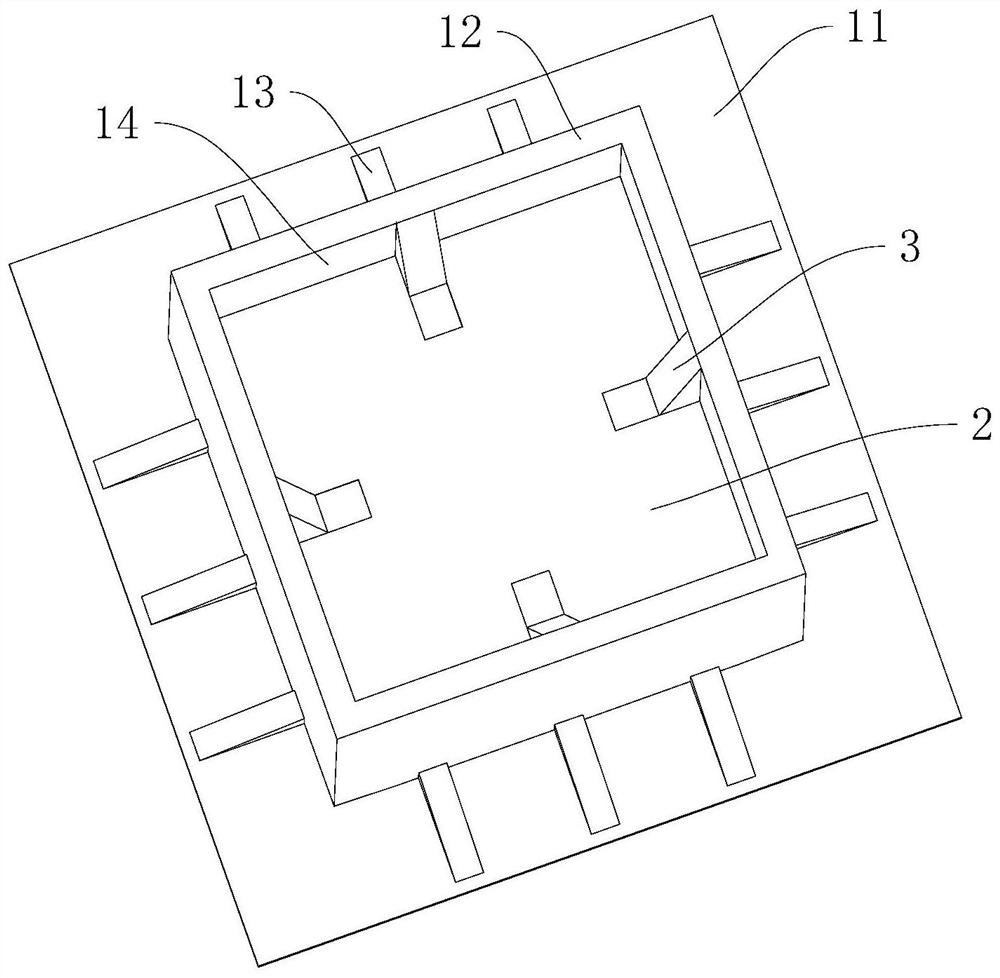

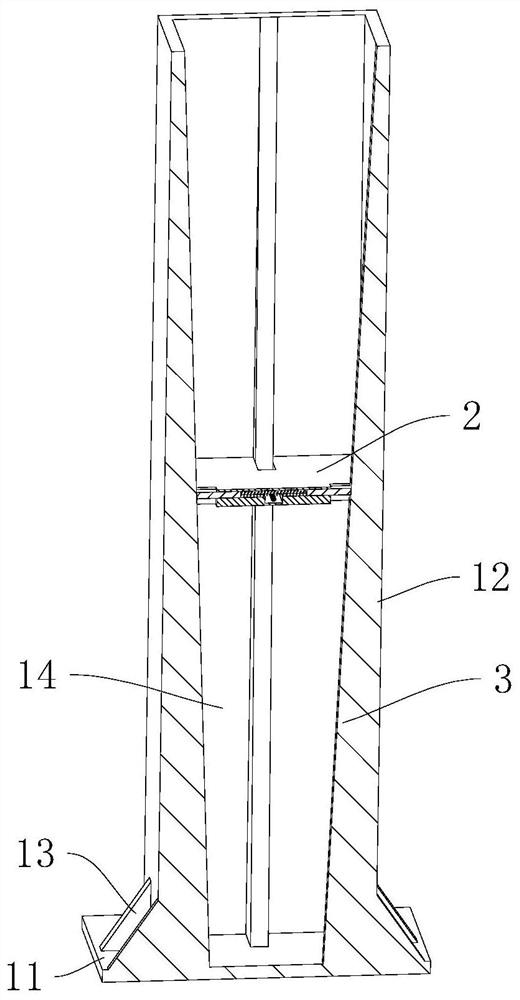

[0044] refer to figure 1 , 2 , the steel structure support column filled with concrete includes a column body 1 and a buffer plate 2 .

[0045] The column body 1 includes a bottom plate 11 , side plates 12 and reinforcing ribs 13 . The base plate 11 is horizontal, and the lower surface of the base plate 11 is used to contact the ground; the side plates 12 are vertically arranged, and the lower ends of the side plates 12 can be fixedly connected to the upper surface of the base plate 11 by welding; at the same time, the four side plates 12 pass The way of welding is enclosed into a rectangle; then a filling cavity 14 is formed above the bottom plate 11 and between the four side plates 12, and the filling cavity 14 is used for concrete filling. The reinforcing rib 13 is connected to the upper surface of the bottom plate 11 by welding, and the reinforcing rib 13 is connected to the lower end of the outer surface of the side plate 12 facing away from the filling cavity 14 to imp...

Embodiment 2

[0061] refer to Image 6 , the difference between this embodiment and embodiment 1 is that

[0062] Two mounting holes 22 are provided and run through the buffer plate 2 , and the two mounting holes 22 are at the same height.

[0063] The friction part 41 can be made of materials that are easy to wear such as rubber; the pressing part 42 uses a magnet 422, and the magnet 422 and the support member 3 can be attracted to each other by magnetic force; Mutual repulsion, so that the two opposite pressing pieces 4 have a tendency to move away from each other.

[0064] The implementation principle of Embodiment 2 is: as the concrete slurry is continuously injected into the filling cavity 14, the downward force exerted by the concrete slurry on the buffer plate 2 increases continuously; The support 3 moves down synchronously. On the one hand, the sliding friction between the friction part 41 and the friction surface 31 makes the friction part 41 wear, and the distance between the ma...

Embodiment 3

[0066] refer to Figure 7 , 8 , the difference between this embodiment and embodiment 1 is that

[0067] The pressing member 4 is fixedly connected to the buffer plate 2 and is located in the avoidance groove 21, and the thickness of the pressing member 4 decreases as it approaches the support member 3; and, the pressing member 4 moves down with the buffer plate 2 relative to the support member 3 At this time, the edge of the support member 3 cuts the resisting member 4, so that the resisting member 4 and the buffer plate 2 are sheared and fractured at the inner wall of the escape groove 21 .

[0068] The implementation principle of Embodiment 3 is: when the edge of the supporting member 3 cuts the pressing member 4, the thicker the pressing member 4 is, the greater the force required for cutting, the greater the corresponding reaction force, and the reaction force That is, the resistance received by the pressing member 4; then the resistance received by the pressing member ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com