Centrifugal fire pump

A centrifugal and water pump technology, which is applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problem of affecting the restart of the centrifugal fire-fighting water pump, the poor protection effect of the centrifugal fire-fighting water pump, and the damage of the centrifugal fire-fighting water pump and other problems, to achieve the effect of being easy to restart and use, improving the protection effect, and realizing the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

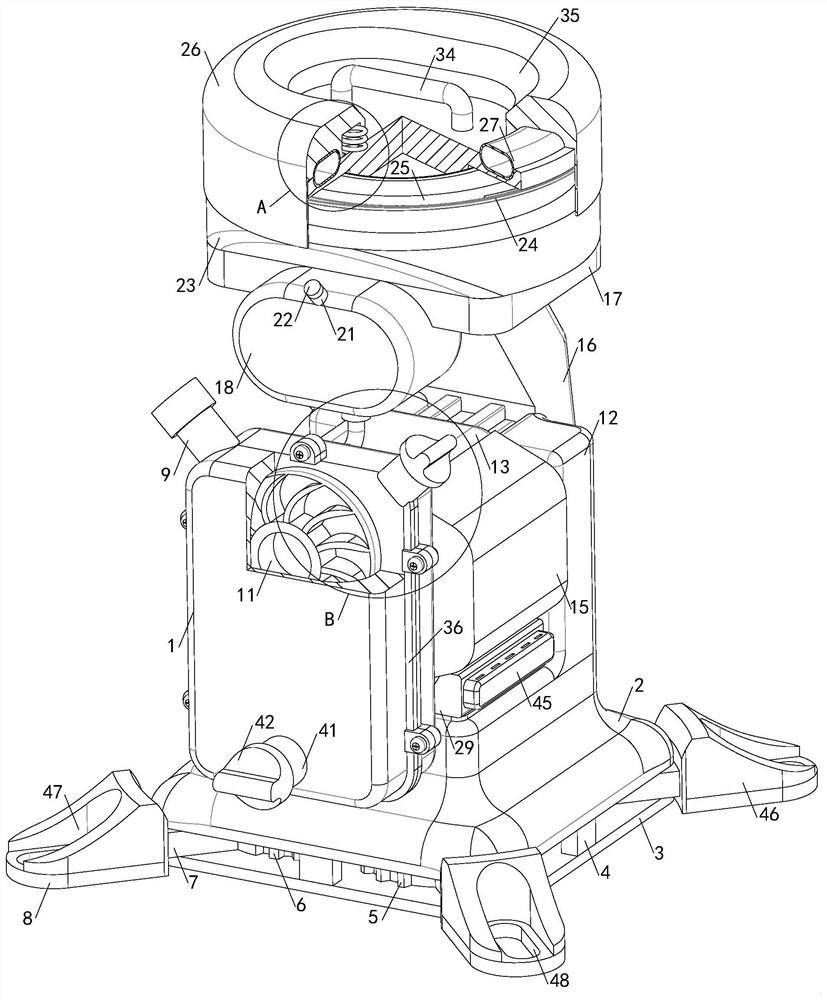

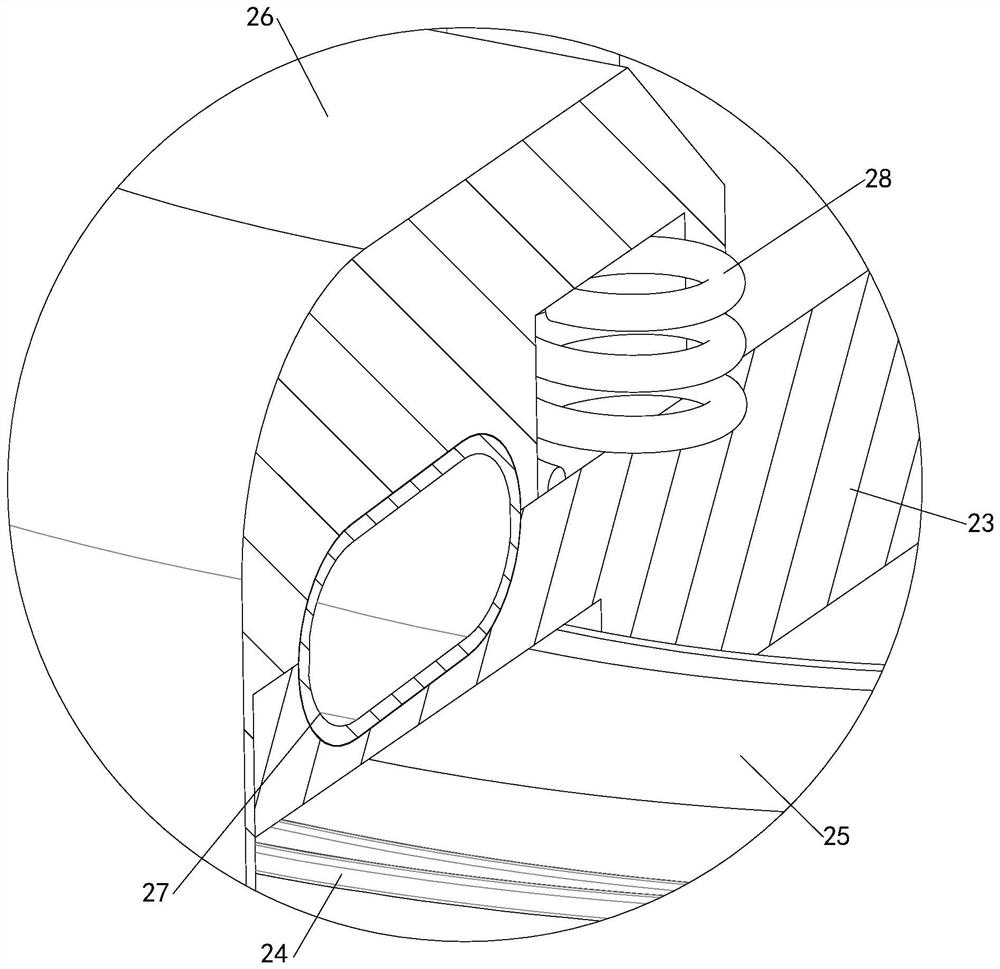

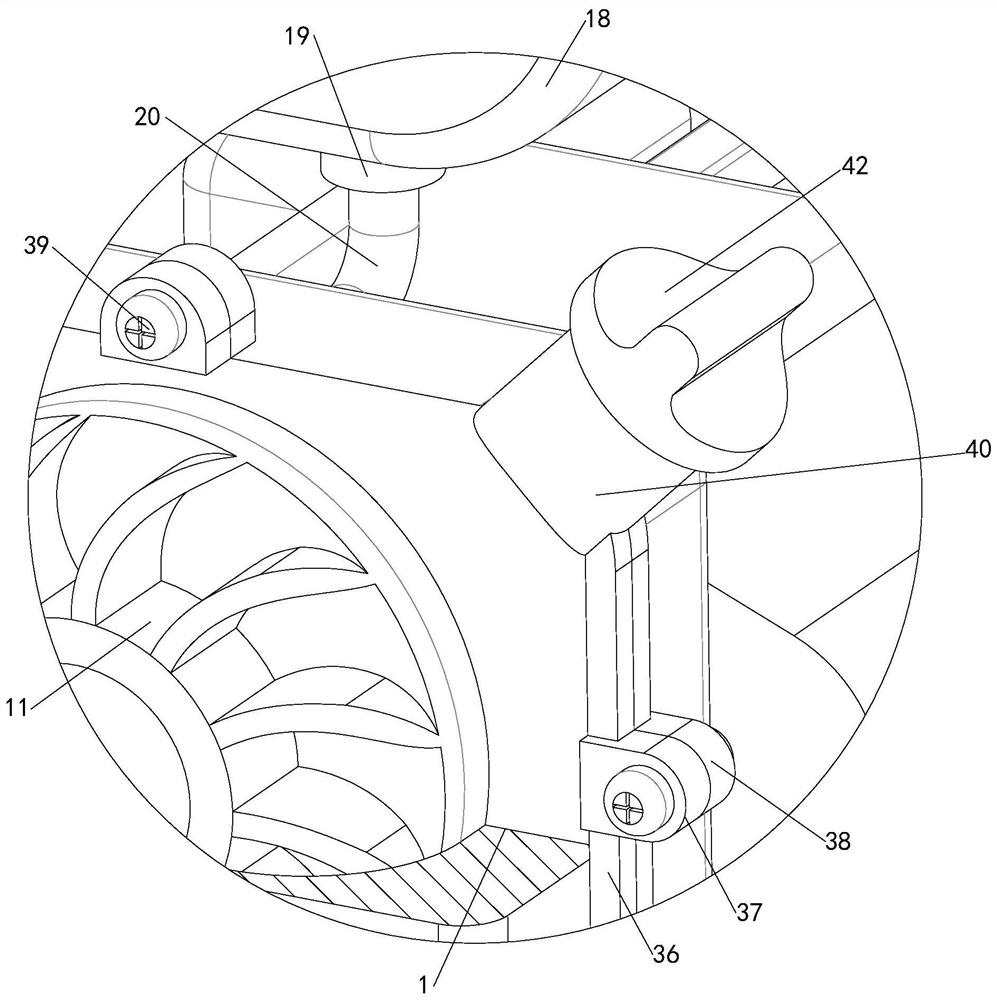

[0034] see Figure 1-8, a centrifugal fire pump, including a sealed chamber 1, and also includes an underframe 2 and a bottom plate 3, the underframe 2 and the bottom plate 3 are fixedly connected by a plurality of connecting blocks 4, and the bottom frame 2 and the bottom plate 3 are rotatably connected with Two main gears 5 and two sub-gears 6, two main gears 5 and two sub-gears 6 are arranged at intervals, adjacent main gears 5 and sub-gears 6 mesh with each other, and four mounting ears 8 can move in coordination, thereby It is convenient for the synchronous adjustment of the four mounting ears 8, and the practicability is better. Both the female gear 5 and the child gear 6 are fixedly connected with the connecting bar 7, and the end of the connecting bar 7 far away from the bottom frame 2 is fixedly connected with the mounting ear 8, so that During the installation process with the outside world, the position of the mounting ear 8 relative to the chassis 2 can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com