A semi-active vibration-absorbing and energy-dissipating control system for suppressing bridge vortex-induced vibration

A control system, vortex-induced vibration technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of low vertical bending vortex vibration frequency of bridges, reduced applicability, large mass, etc., to reduce the weight of the mass body and reduce the spring Quality and cost, the effect of the small size of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with technical scheme and accompanying drawing, describe the specific embodiment of the present invention in detail, but the embodiment of the present invention is not limited thereto:

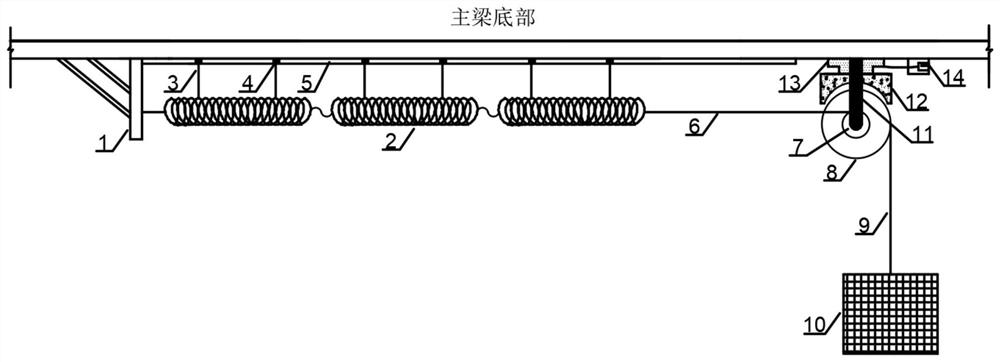

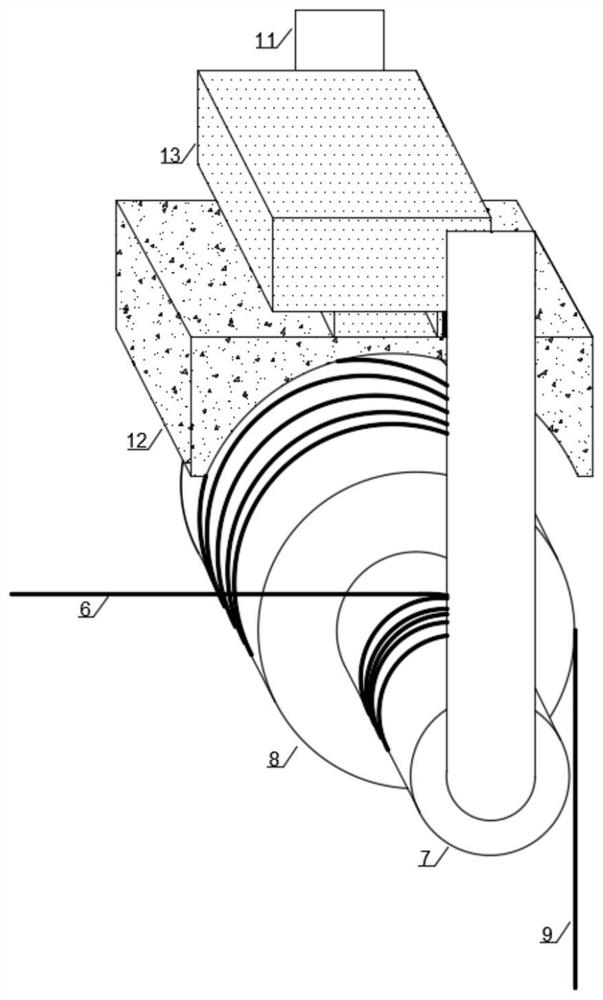

[0029] Such as figure 1 As shown, a semi-active vibration-absorbing and energy-dissipating control system for suppressing vortex-induced vibration of a long-span bridge includes a spring end plate 1 fixed on the bottom plate of the main girder, a linear tension spring 2, a vertical suspension rope 3, a slider 4, a slider Road 5, first high-strength rope 6, first pulley 7, second pulley 8, second high-strength rope 9, mass body 10, pulley fixing device 11, energy dissipation device 12, electric control jack 13, controller 14; spring end The plate 1 is usually set on the bottom of the main girder or on the pier (tower, platform), and can be made of a stiffened steel plate, which is used to fix one or several linear tension springs 2 arranged in series or in parallel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com