A flexible tactile sensing array, its preparation method and its application

A tactile sensing and flexible technology, applied in the field of flexible tactile sensing arrays and preparations, can solve the problems of low sensor sensitivity, poor piezoresistive performance, poor accuracy and reliability, etc., achieve simple data processing and improve accuracy and reliability, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

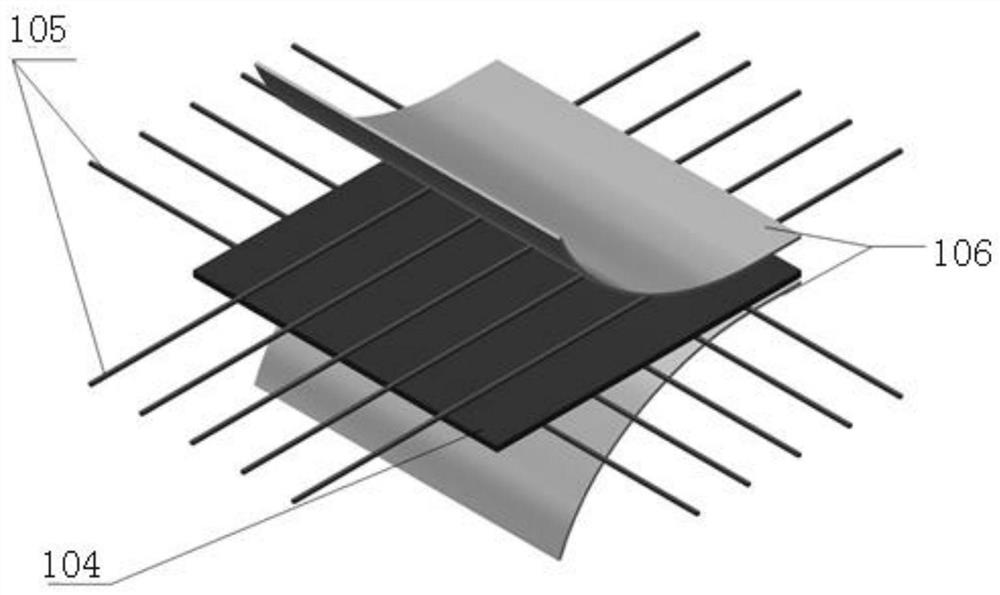

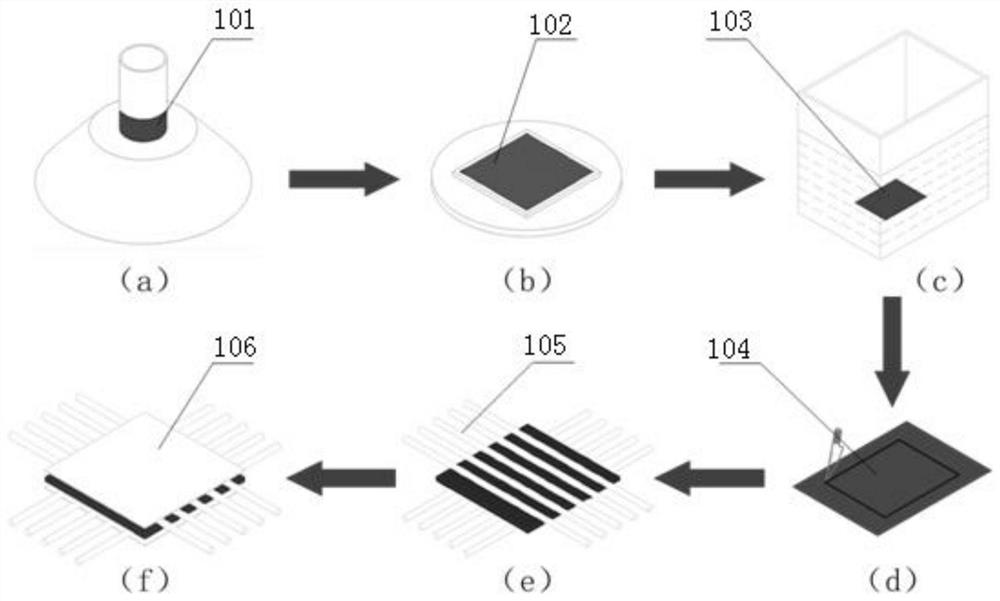

[0062] The invention provides a preparation method of a flexible tactile sensing array, refer to figure 2 As shown in (a) to (f) of the above, it includes the following steps:

[0063] (1) If figure 2 As shown in (a), the NaCl particles were placed in a mortar and ground to less than 100 μm, and then according to the mass ratio of 1:5:5, 1.6g CB, 8gTPU and 8gNaCl were sequentially taken out and placed in a test tube, and the test tube was placed in a high-speed vibration. The apparatus was continuously vibrated at the highest power for 5 minutes to make the powder mix evenly, and in this way, a conductive powder 201 with CB, TPU and NaCl fully mixed was obtained.

[0064] (2) If figure 2 As shown in (b), the conductive powder 201 is placed in an acrylic template, and an elastic colloidal film 202 is prepared by first heating and then cooling. Specifically, firstly use acetone, isopropanol and deionized water to clean the glass sheet in sequence, and evenly spray RD-518 f...

Embodiment 2-7

[0070] Examples 2-7 prepare flexible tactile sensing arrays in the same manner as in Example 1, except that the difference from Example 1 is that the mass ratios of nano-carbon black, thermoplastic polyurethane rubber, and NaCl powder are different, See Table 1 below for details.

[0071] Table 1 Mass ratio table of CB, TPU and NaCl

[0072] Mass ratio of CB, TPU and NaCl Example 2 0.05:1:1 Example 3 0.1:1:1 Example 4 0.2:1:1 Example 5 0.3:1:1 Example 6 0.02:1:1 Example 7 0.4:1:1

[0073] The resistance value test is carried out on the flexible tactile sensing array prepared by the method provided in Examples 2-7, see Figure 5 , it can be seen that in the process that the mass of CB gradually increases relative to the mass of TPU, the resistance value of the sensing unit gradually decreases, and in the pressure range of 0-5N, the sensitivity of the sensing unit increases first The trend of decreasing after large, and when ...

Embodiment 8

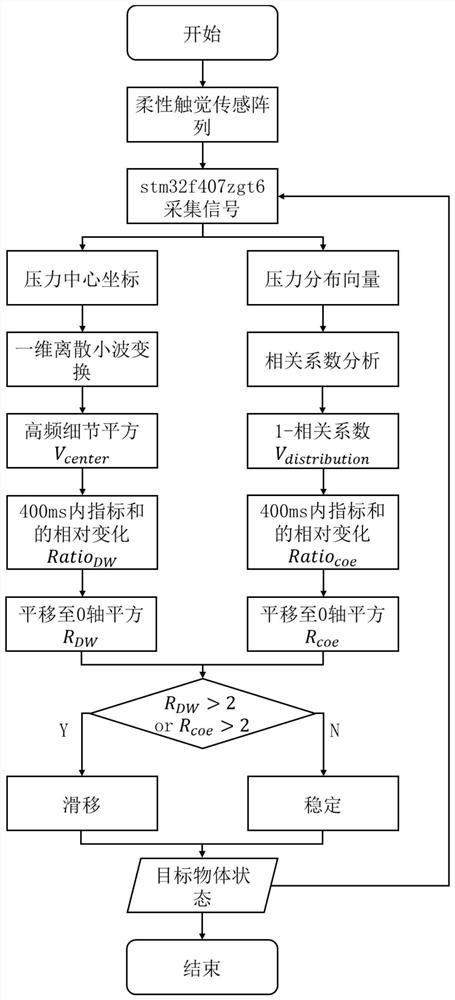

[0075] This embodiment provides an application of the flexible tactile sensing array, which is applied to slip detection of robot operation. see image 3 , the detection includes the following steps:

[0076] (1) Collect the voltage signal of each tactile sensing unit in the flexible tactile sensing array, convert the voltage signal into its corresponding pressure, and perform one-dimensional discrete wavelet transform processing on the pressure to obtain high-frequency detail data .

[0077] Specifically, the step (1) includes the following substeps:

[0078] (101) Collect the voltage signal of each tactile sensing unit in the flexible tactile sensing array, convert the voltage signal into its corresponding pressure, and establish a two-dimensional coordinate system with the flexible tactile sensing array as a plane. In the coordinate system, the coordinates of the tactile sensing unit in the lower left corner are (1, 1), and the coordinates of the tactile sensing unit in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com