Active pressure compensation device and method and double-wheel slot milling machine

A pressure compensation, active technology, applied in electric fluid pressure control, earth mover/shovel, construction, etc., can solve the problem that the two-wheel groove milling machine cannot meet the working requirements, and the pressure difference cannot change with the water depth. Changes due to changes, working equipment oil leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

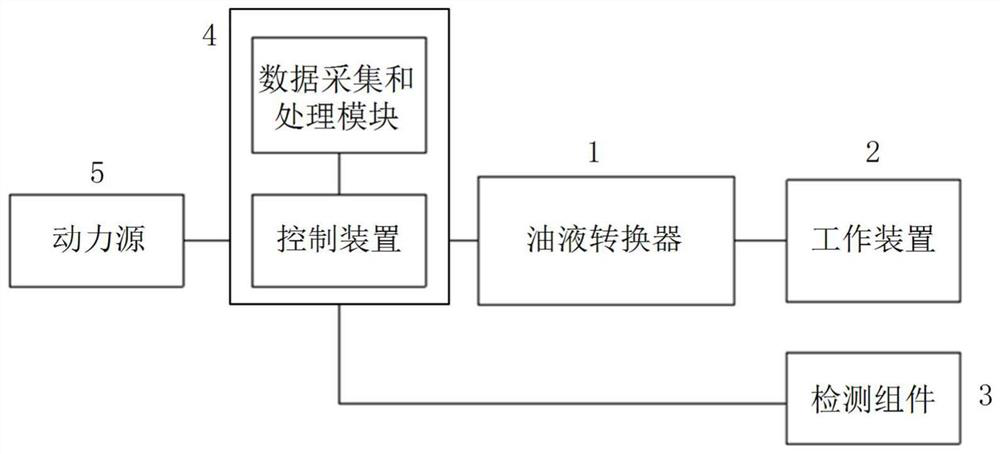

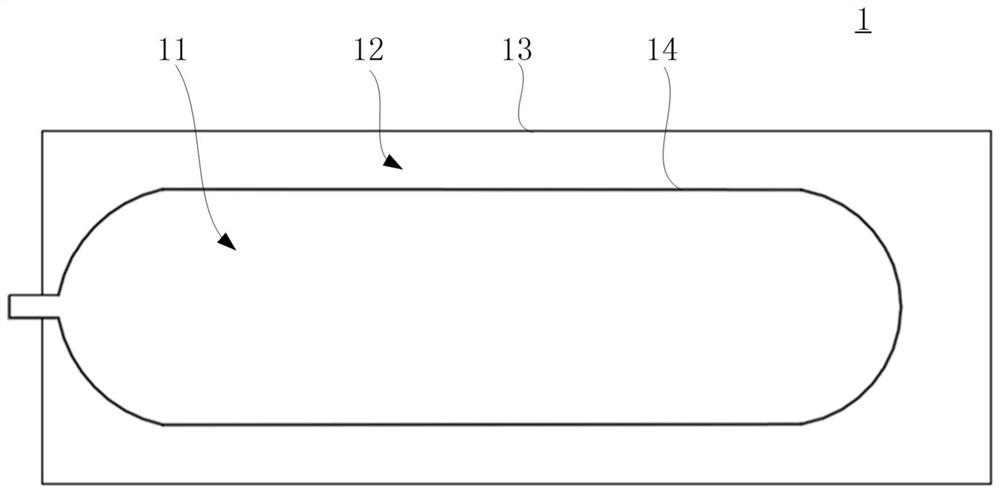

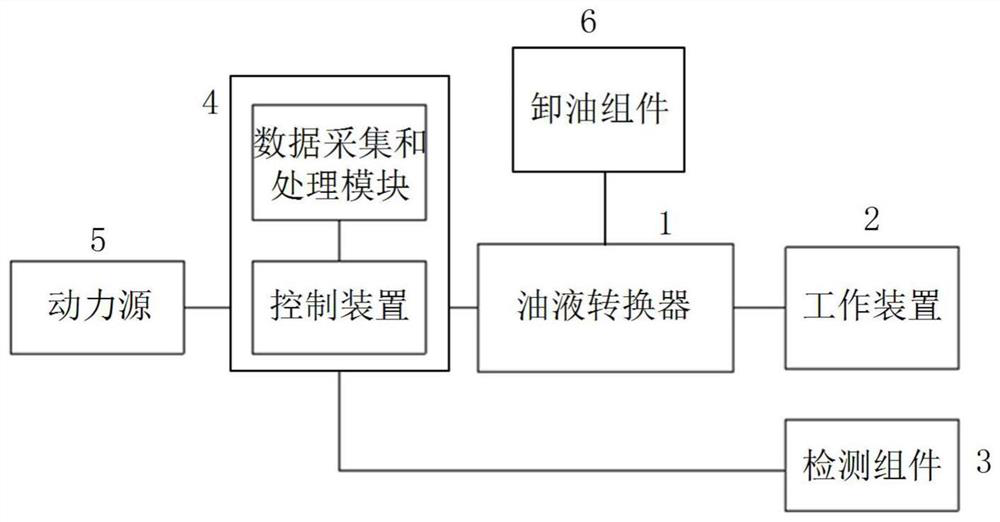

[0055] Combine below Figure 1 to Figure 7 The technical solution provided by the present invention is described in more detail.

[0056] An embodiment of the present invention provides an active pressure compensation device. To facilitate explanation and description of the technical solution of the embodiment of the present invention, the application of the active pressure compensation device to a double-wheel slot milling machine is taken as an example. When the double-wheel slot milling machine works underwater, as the working depth increases, the external pressure on the working device 2 gradually increases. In order to reduce and prevent the risk of the working device 2 entering muddy water due to the failure of the seal, it is necessary to increase the internal pressure of the working device 2 so that the internal pressure of the working device 2 is equal to or slightly greater than the external environmental pressure, and the above compensation operation is performed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com