Snake bone linkage structure

A technology of snake bone and rotating structure, which is applied in pivot connection, medical science, endoscope, etc. It can solve the problems of laborious operation, low flexibility of snake bone tube, and small range of motion, so as to reduce production cost and improve The effect of product consistency and large range of activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

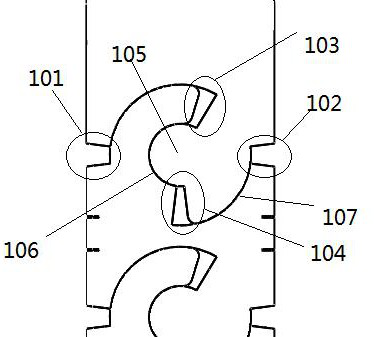

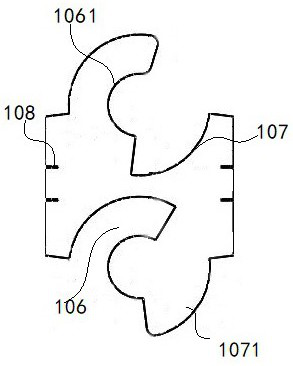

[0032] refer to Figure 1-Figure 5 , a snake bone link structure, the snake bone link structure is integrally formed by laser cutting a metal tube, the link structure includes a patterned rotating structure 1, and the patterned rotating structure 1 includes a primary rotating part and is compatible with the primary rotating part The second-stage rotating part is provided, the first-stage rotating part includes a first-stage arc-shaped slide block 1061 and the second-stage arc-shaped slideway 107, the second-stage rotating part includes a first-stage arc-shaped slideway 106 and a second-stage arc-shaped slide block 1071, and one The first-level arc slide block 1061 is compatible with the first-level arc slideway 106, the second-level arc slide block 1071 is compatible with the second-level arc slideway 107, the first-level arc slide block 1061, the second-level arc slideway Road 107, primary arc slideway 106 and secondary arc slide block 1071 are concentric arcs;

[0033] When...

Embodiment 2

[0036] Others are consistent with the scheme of Embodiment 1. The link structure of the snake bone is a two-way snake bone link structure, and the link structure includes patterned rotating structures 1 symmetrically distributed on the metal circular tube.

Embodiment 3

[0038] The rest are consistent with the scheme of embodiment 1 or 2. The metal round pipe includes a metal pipe and a front connecting pipe and a rear connecting pipe arranged at both ends of the metal pipe. The length of the front connecting pipe is shorter than the length of the rear connecting pipe. Ensure that the joint section at the front end of the metal tube is relatively short, and the joint section at the rear end is relatively long, so as to ensure that the front end moves first when the overall snake bone bends, so that it is more flexible and labor-saving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com