Single-servo precise gear pump metering and distribution system and method thereof

A technology of dispensing system and gear pump, applied in the direction of coating, device for coating liquid on the surface, etc., can solve the problems of small viscosity range of glue, poor dispensing accuracy, and short life of dispensing products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

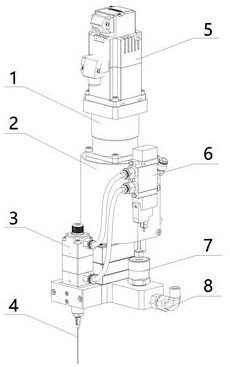

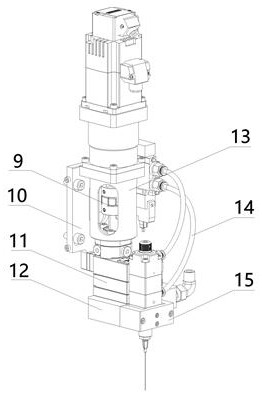

[0029] Such as figure 1 , figure 2 The shown single-servo accurate gear pump metering distribution system uses a square aluminum back fixing plate 10 as support and main connection, the servo motor 5 is connected to the reducer 1, and the reducer 1 and the gear pump 11 are fixedly connected through the connecting piece 13. The connecting piece 13 is connected with the back fixing plate 10, and the back fixing plate 10 is connected with a shield 2 to wrap the connecting piece 13. The mounting hole on the back of the gear pump 11 can be installed on the back fixing plate 10. The shaft device 9 connects the power output shaft of the speed reducer 1 and the central shaft of the gear pump 11 . The upper part of the flow channel connection block 12 is connected to the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com