Wood processing cutting machine convenient to collect wood chips

A cutting machine and sawdust technology, which is applied in the field of wood processing, can solve the problems of scattered sawdust, sawdust jamming, equipment damage, etc., and achieve the effects of prolonging the service life, facilitating collection, and preventing scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

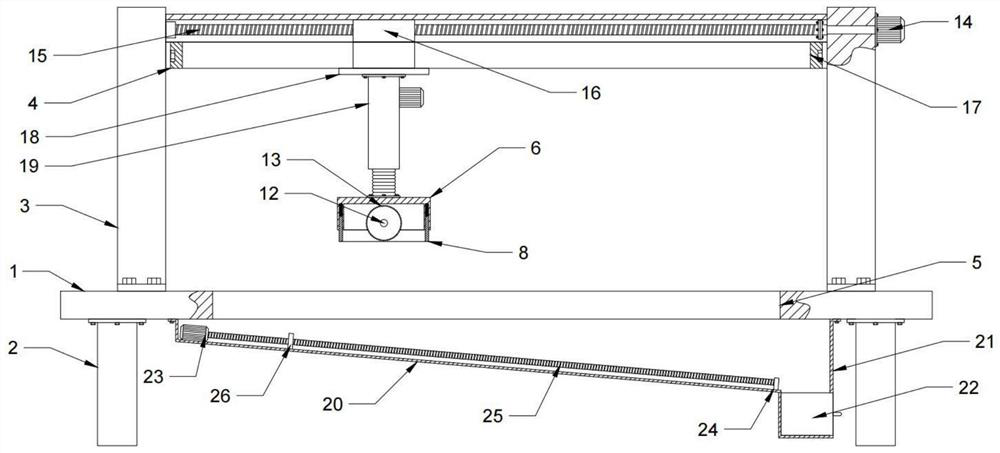

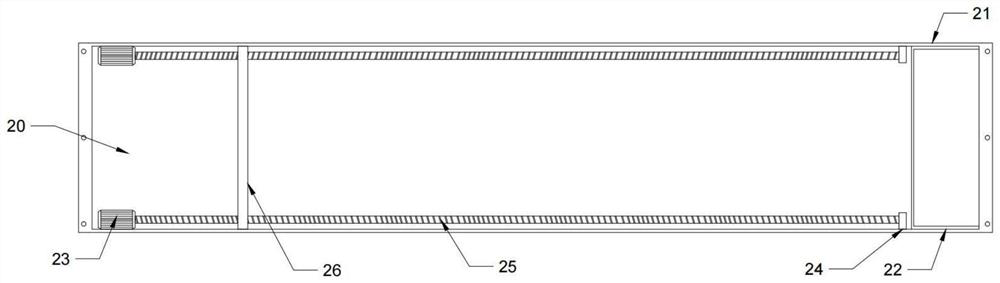

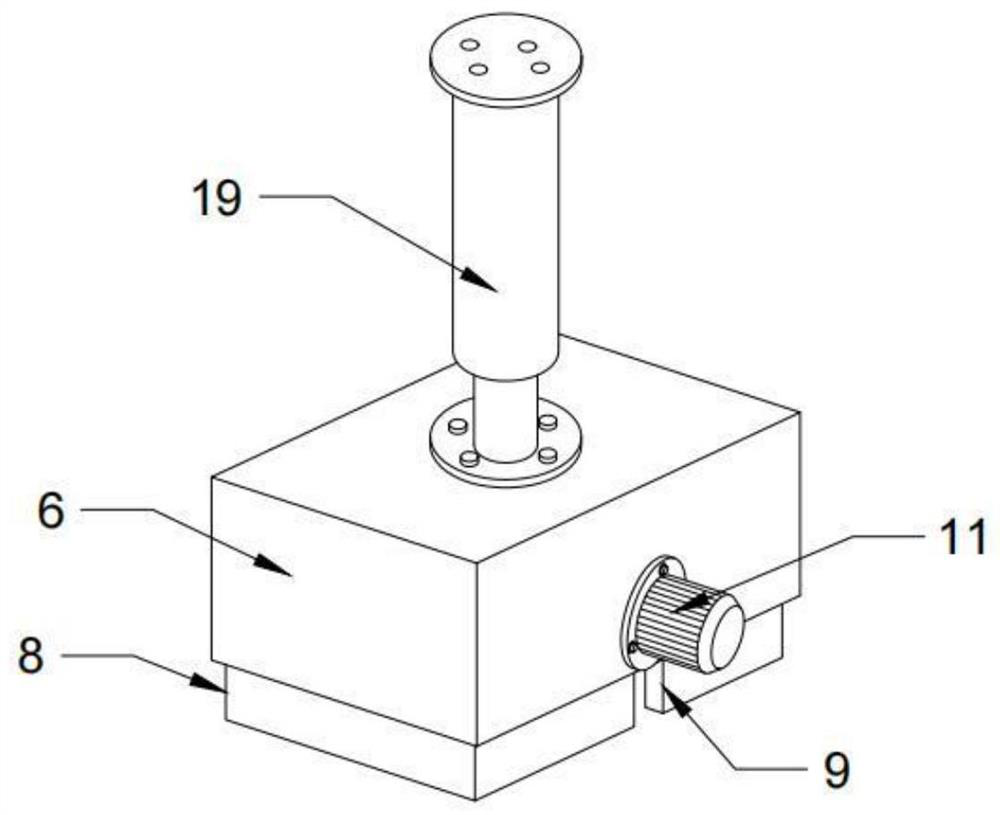

[0020] combined with figure 1 to attach Figure 5 , a cutting machine for wood processing that is convenient for collecting sawdust, including a workbench 1, support legs 2 are fixed at the four corners of the workbench 1 by bolts, and vertical plates are fixed by bolts on both sides of the workbench 1 3. A horizontal plate 4 is fixed by bolts between the upper ends of the vertical plates 3. A moving structure is installed on and through the horizontal plate 4, and a telescopic structure is installed on the extending end of the moving structure. A chip retaining structure is installed at the lower end of the telescopic structure, a cutting structure is installed in the chip retaining structure, and a strip-shaped through hole 5 corresponding to the cutting structure is opened on the workbench 1, and the workbench 1 A sawdust collection structure is installe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap