Municipal drain board pouring equipment

A technology of drainage board and equipment, applied in cement mixing device, clay preparation device, supply device, etc., can solve the problems of low efficiency, high work intensity and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

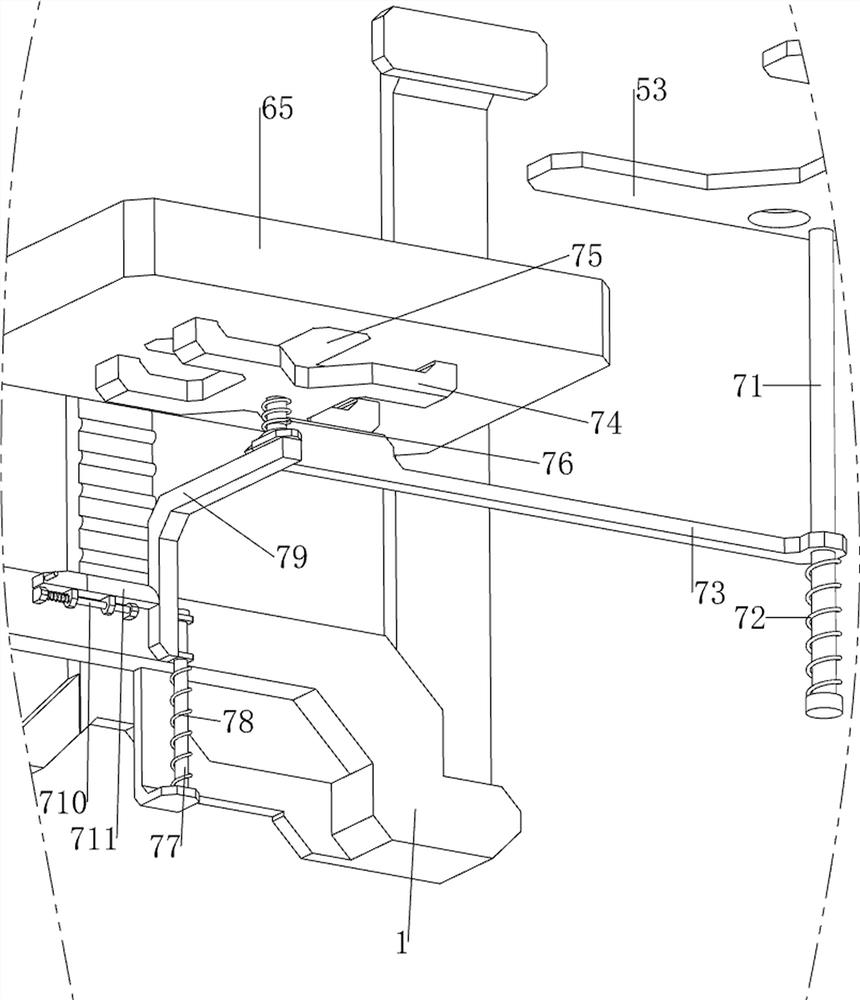

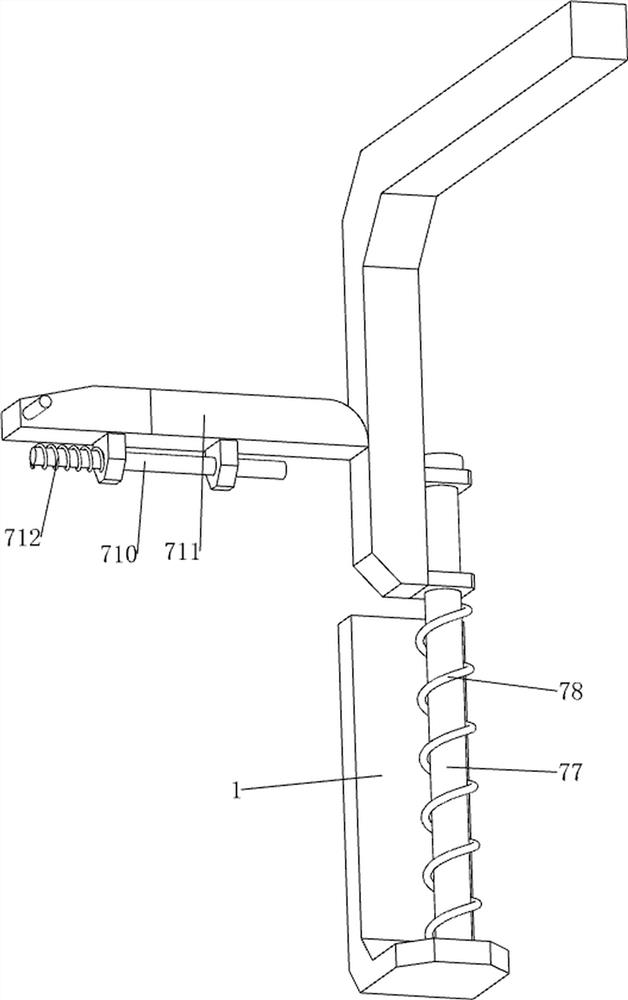

[0067] A municipal drainage board pouring equipment, such as Figure 1-4As shown, it includes a support frame 1, a stirring block 2, a stirring mechanism 3, an extruding mechanism 4 and a discharge mechanism 5. The upper side of the support frame 1 rear part is provided with a stirring mechanism 3, and the rotating type in the stirring mechanism 3 is provided with sixteen Block stirring block 2, mixing mechanism 3 is provided with extruding mechanism 4, and stirring mechanism 3 cooperates with extruding mechanism 4, and support frame 1 upper rear side is provided with discharging mechanism 5, and one side of discharging mechanism 5 is connected with extruding mechanism 4 sliding connections.

[0068] Workers first pour an appropriate amount of cement and water into the mixing mechanism 3, start the mixing mechanism 3, the operation of the mixing mechanism 3 drives the operation of the mixing block 2, and the operation of the stirring block 2 will mix the cement and water, so a...

Embodiment 2

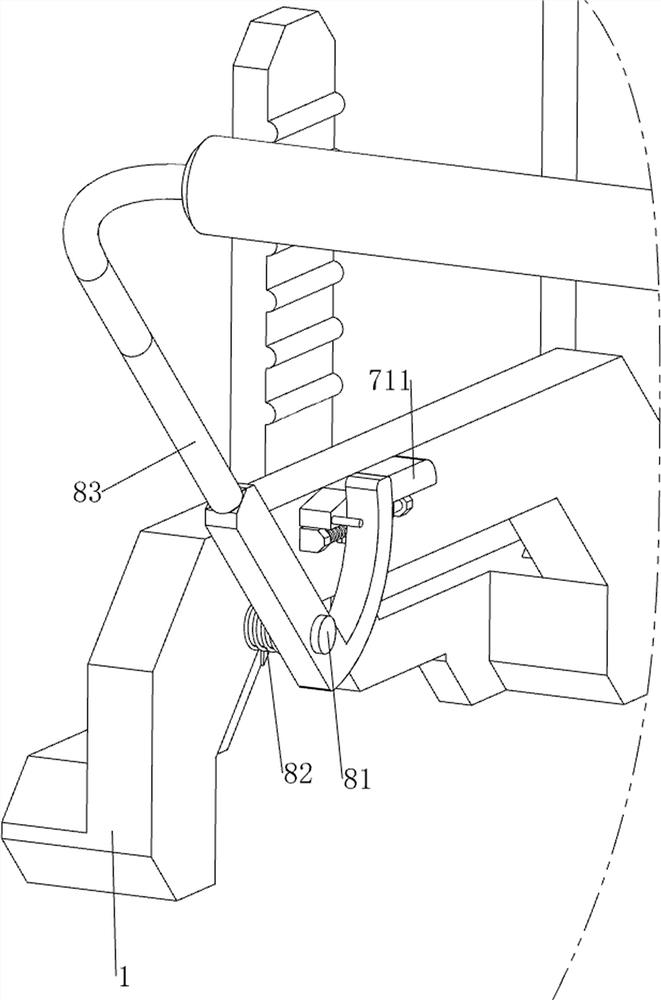

[0076] On the basis of Example 1, such as Figure 5-8 As shown, a forming mechanism 6 is also included, and the forming mechanism 6 includes a first pressing block 61, a first fixed rod 62, a first spring 63, a first slide block 64, a forming frame 65 and a second spring 66, and a material retaining plate 53, the upper, rear, left, and right sides are provided with first pressing blocks 61, and the front, left, and right sides of the support frame 1 are symmetrically provided with first fixed rods 62, and the vertical two first fixed rods 62 are slidably connected with The first slider 64, the first slider 64 on the same side cooperates with the first pressure block 61 on the same side, the first spring 63 is wound on the first fixed rod 62, and the first spring 63 is connected between the support frame 1 and the first Between the sliders 64, a molding frame 65 is slidably connected between the two longitudinal first sliders 64, and two second springs 66 are wound around the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com