Guide wheel variable stiffness design method and variable stiffness guide wheel

A design method and variable stiffness technology, which are applied in the direction of wheels, wheels characterized by track running parts, transportation and packaging, etc., can solve the problems of large space for guide wheels and high cost of guide devices, achieve low cost, avoid potential safety hazards, small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

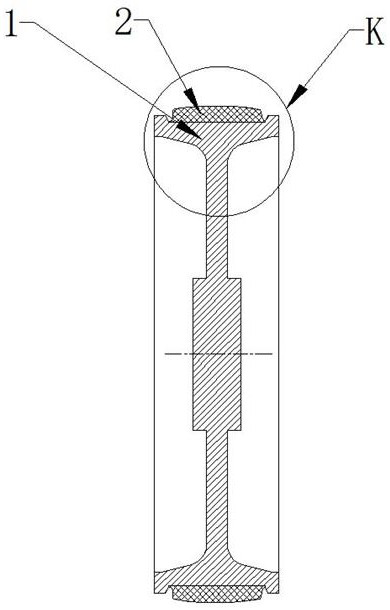

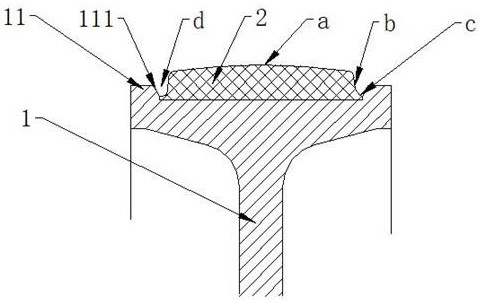

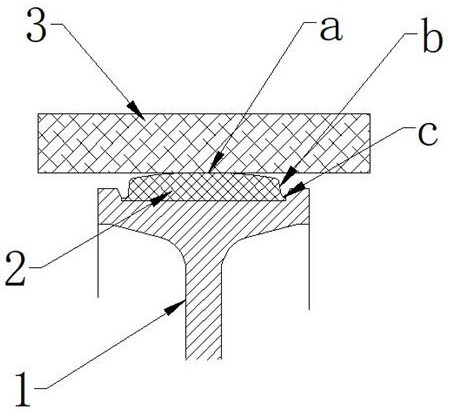

[0031] Guide wheels such as Figures 1 to 2As shown: including the hub 1 and the elastic layer 2, the two sides of the hub 1 are provided with flanges 11, and the flanges 11 on both sides are combined with the outer ring of the hub 1 to form a circular groove. The opposite side of the flanges 11 on both sides is the flange inner surface 111, and the flange inner surface 111 is a slope, so that the width of the opening of the groove is greater than the width of the bottom of the groove, so that the cross section of the groove is an inverted trapezoid.

[0032] The elastic layer 2 is embedded in the groove of the outer ring of the hub 1 by using elastic materials such as rubber and plastic, and rubber is used in this embodiment. The inner ring of the elastic layer 2 is fixedly connected with the outer ring of the hub 1 by means of vulcanization or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com