Automatic anchor bolt thermal shrinkage packaging production line

A packaging production line, heat shrinking technology, applied in packaging, wrapping paper, shrinkage of wrapping paper, etc., can solve the problems of low production efficiency and high labor intensity of workers, reduce labor intensity and labor costs of workers, and improve heat shrink processing efficiency , Convenience for centralized transportation and overall packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

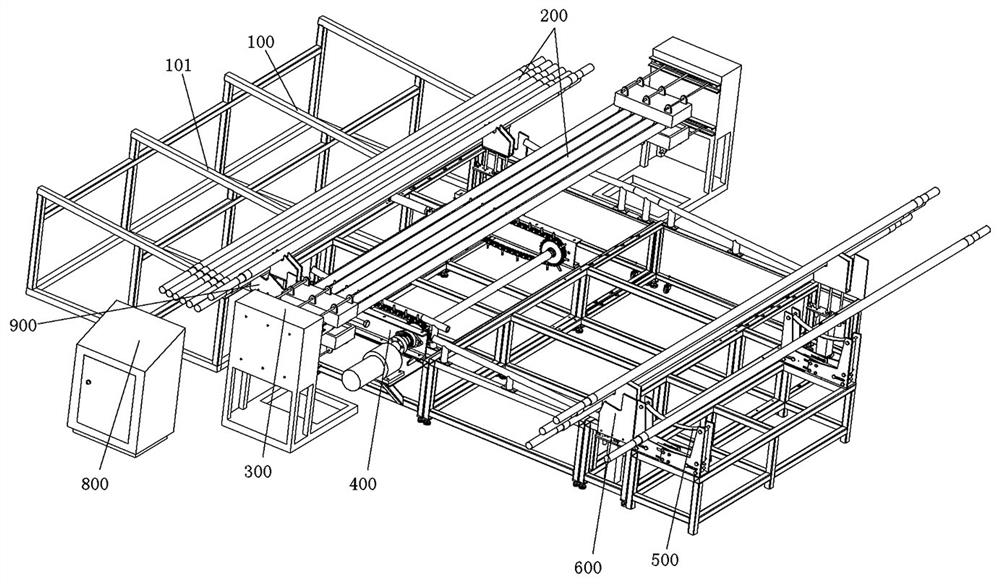

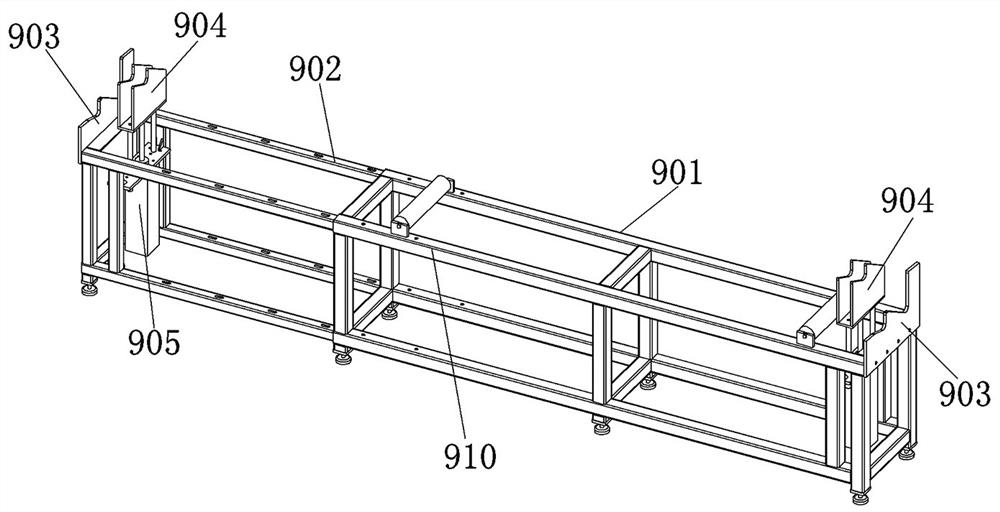

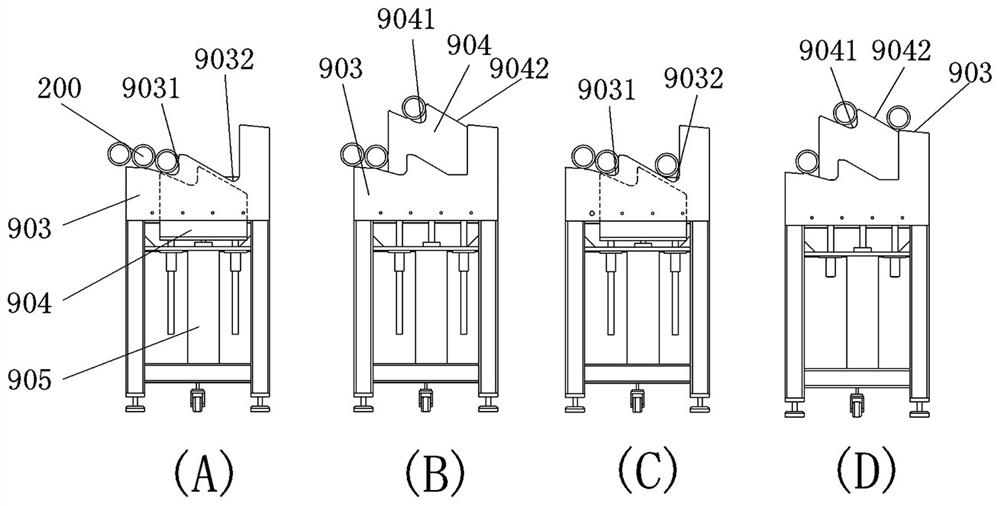

specific Embodiment 1

[0052] The structure of the corresponding anchor bolt 200 is as Figure 12 As shown, it has the same structure as the anchor bolt 200 with heat-shrinkable tube 3 commonly used in the prior art, so it will not be repeated here. The heat-shrinkable packaging production line provided in this embodiment is mainly used for heat-shrinkable processing of the anchor bolt 200 , Reduce the degree of manual participation and improve production efficiency. Such as Figure 1 to Figure 12 As shown, the anchor bolt automatic heat-shrinkable packaging production line in this embodiment as a whole includes a feeding unit 100, a heat-shrinking unit 400, and a receiving unit 500 arranged sequentially from back to front, wherein the feeding unit 100 is used to store several anchor bolt 200, and use the feeding mechanism 900 to transport the anchor bolt 200 to the heat shrink unit 400, and the heat shrink unit 400 heats the heat shrinkable tubes 3 on both sides of the multiple anchor bolts 200 to ...

specific Embodiment 2

[0084] The main difference between it and Embodiment 1 lies in that in Embodiment 1, the circular conveying member is a conveying chain, which is correspondingly driven by a sprocket. In this embodiment, the endless conveying member is a conveying belt, which is correspondingly driven by a pulley. At this time, a driving pulley and a driven pulley are correspondingly arranged on the mounting frame. The shafts are connected by synchronous transmission, and the pushing blocks are distributed on the conveyor belt at intervals along the circumference of the conveyor belt. During the rotation of the conveyor belt, the pushing blocks drive the anchor bolts to roll and move forward.

[0085] Of course, there are two conveying chains arranged at intervals along the left and right directions in Embodiment 1. In this embodiment, more than three conveying belts can be arranged at intervals along the left and right directions, which can be determined according to the actual required pushin...

specific Embodiment 3

[0087] The difference of Embodiment 1 is mainly that: in Embodiment 1, there are two anchor bolt support rods arranged at intervals along the left and right directions, corresponding to supporting the left and right ends of the anchor bolt. In this embodiment, there may be more than three anchor bolt support rods arranged at intervals along the left and right directions, which may be specifically designed according to the length of the anchor bolt. Correspondingly, there are more than three conveying support rods arranged at intervals along the left and right directions, which can also be arranged according to the length of the bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com