Screening type spiral conveying device capable of heating and drying

A screw conveying device and screening technology, which is applied in the field of screening screw conveying devices, can solve the problems of drying materials that cannot be wetted, do not have a drying function, and materials are moldy and deteriorated, and achieve enhanced screening and drying effects, Effect of increasing screening and drying time, enhancing processing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

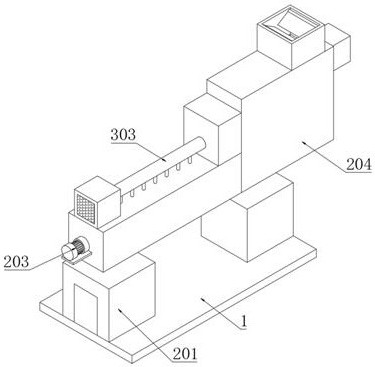

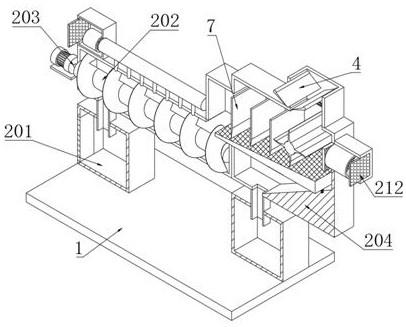

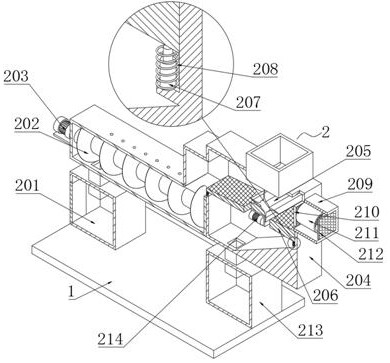

[0038] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, a heating and drying screening type screw conveying device, including a base 1, which is convenient for the staff to disperse and stir the materials, and also facilitates the staff to vibrate and screen the materials, and then Improve the drying and screening effect of the device, thereby enhancing the processing rate of the device for materials. The top of the base 1 is equipped with a drying and screening mechanism 2;

[0039] The drying and screening mechanism 2 includes a transfer box 201, an auger 202, a motor 203, a feed box 204, a rotating wheel 205, a screening plate 206, a shock absorbing telescopic rod 207, a shock absorbing spring 208, a fixed box 209, and a protective plate 210 , hot air blower 211, the first dust filter plate 212, waste box 213 and vibration motor 214;

[0040]The top of the base 1 is connected to the transfer box 201, the top of the transfer box 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com