Continuous weighing system for small products and weighing method thereof

A weighing system and product technology, which is applied in the fields of chemicals and manufacturing, pharmaceuticals, and food, can solve the problems of inaccurate weighing results, inaccurate weighing results, inconsistent front and rear positions, etc., to reduce damage or leakage Reduce the risk of dust, shorten the weighing cycle, and ensure the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

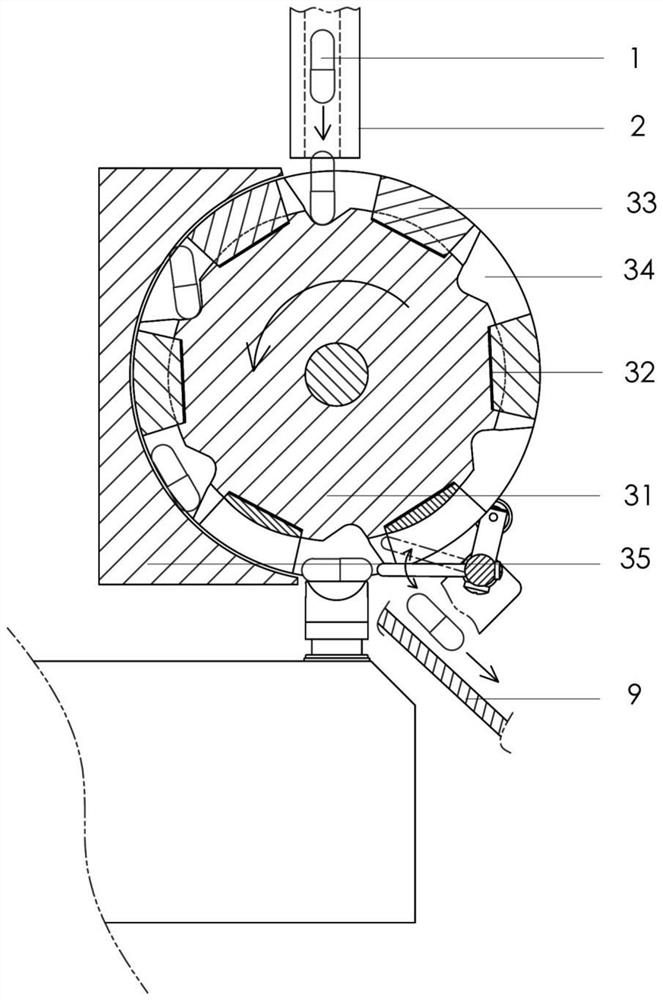

[0072] This embodiment provides a preferred implementation, based on the above structure, such as Figure 3 to Figure 5As shown, in this embodiment, several sliding blocks 33 axially reciprocate in the first channel 32 . The reset mechanism can adopt any mechanical structure that can realize the reset of the push rod 4 in the extreme position to the initial position. Preferably, the reset mechanism can use an elastic element, the elastic element is arranged on the side wall of the first channel 32 away from the push rod 4, and the push rod 4 in the extreme position is reset to the initial position through the elasticity of the elastic element; preferably, the reset The mechanism can adopt a mechanical structure combining elastic elements and guide rails. The guide rails are installed axially along the first passage 32. The slider 33 in the first passage 32 slides along the guide rails. Install elastic elements on the guide rails. The elasticity of the elastic elements will be ...

Embodiment 2

[0088] This embodiment provides a preferred implementation, based on the above structure, such as Figure 6 to Figure 8 As shown, in the present embodiment, on the end face of the same side of the transfer wheel 31 and the push rod 4, several slideways 8 are opened along the circumference of the end face toward the center of the end face; 8 reciprocating movement. The reset mechanism can adopt any mechanical structure that can reset the push rod 4 in the extreme position to the initial position. Preferably, the reset mechanism can use an elastic element, the elastic element is arranged at the bottom of the first passage 32, and contacts with the slider 33 in the first passage 32, and the push rod 4 in the extreme position is reset to the initial state through the elasticity of the elastic element Location. like Figure 8 As shown, the second cam 53 is in the shape of a semi-arc as a whole, the opening of the second cam 53 faces upwards, and the opening surface of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com