Concrete wall surface uniform trowelling device for building and using method thereof

A technology for concrete and construction, applied in the direction of construction, building structure, etc., can solve the problems of complex erection, easy adhesion of concrete waste to the wall, affecting work efficiency, etc., to avoid spillage, improve practicability and flexible use. effect of improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

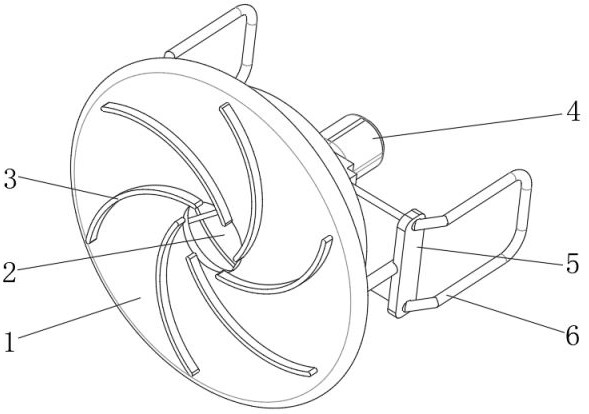

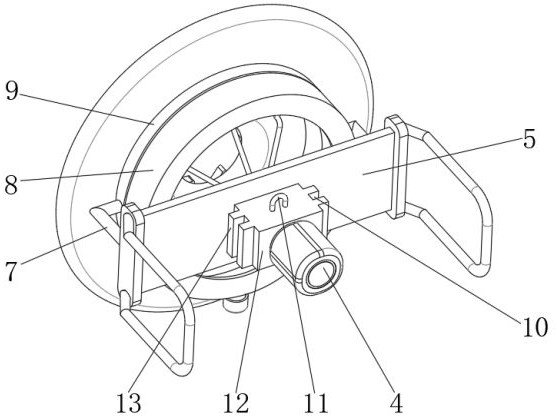

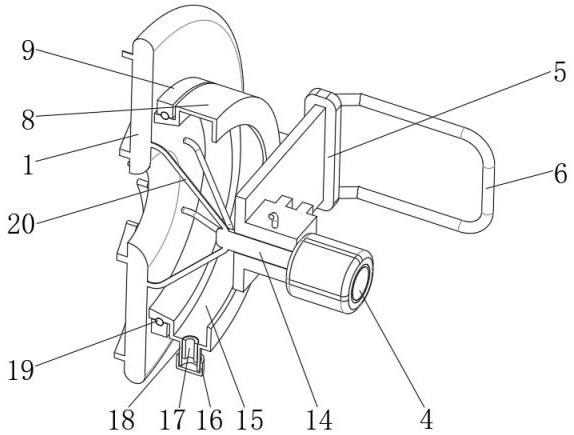

[0040] A kind of uniform smoothing device for concrete wall surface used in construction, such as Figure 1-6As shown, it includes a smoothing box 1 and a mounting plate 5, the outer wall of one side of the mounting plate 5 is fixed with a mounting base 12 by screws, and the outer wall of one side of the mounting base 12 is fixed with a smoothing motor 4 by screws, and the output of the smoothing motor 4 The end is rotatably connected with a rotating main shaft 14, the rotating main shaft 14 runs through the mounting base 12 and the mounting plate 5, and the outer wall of one end of the rotating main shaft 14 is welded with a metal strut 20, and one end of the metal strut 20 is fixed on one side of the troweling box 1 Outer wall, the outer wall of the smoothing box 1 away from the smoothing motor 4 is provided with smoothing arc plates 3 evenly distributed around the circumference, and the center of the smoothing box 1 is provided with a material leakage port 2, and the smoothi...

Embodiment 2

[0044] A kind of uniform smoothing device for concrete wall surface used in construction, such as Figure 3-6 As shown, in order to facilitate large-area troweling work; this embodiment makes the following improvements on the basis of Embodiment 1: the concrete wall evenly troweling device also includes a moving seat 21, and the outer wall of the top of the moving seat 21 is screwed Two symmetrical fixed base frames 30 are fixed, and an adjustment frame 26 is detachably installed on the inner wall of the top; the adjustment frame 26 is in a U-shaped structure, and the outer walls on both sides of the mounting base 12 are integrally provided with four strip-shaped protrusions 13. A chute 10 is formed between two strip-shaped protrusions 13 on the same side. The inner wall of the adjustment frame 26 is integrally provided with a strip-shaped rib 33. The mounting base 12 is slidably connected to the fixed base through the strip-shaped protrusions 13 The inner wall of the frame 30...

Embodiment 3

[0050] A kind of use method of the concrete wall surface uniform smoothing device that a kind of construction is used, such as Figure 1-6 shown, including the following steps:

[0051] S1: The user places a guide rail bar 24 parallel to the concrete wall, and installs the moving seat 21 on the guide rail bar 24;

[0052] S2: according to the size of the concrete wall, use the inserting strip 25 and the slot 22 to splice a plurality of guide rail strips 24;

[0053] S3: According to the size of the concrete wall, adjust the length of the adjusting frame 26 protruding from the fixed base frame 30, and fix it by the threaded knob 32;

[0054] S4: Control the operation of the smoothing motor 4 to drive the smoothing box 1 to rotate for smoothing;

[0055] S5: pull the traction rope 28 through the pull handle 29 to lift the installation seat 12, and perform vertical smoothing on the concrete wall;

[0056] S6: After vertical smoothing, push the moving seat 21 to move a length o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com