Hydraulic retarder with rotor with no-load loss reducing device

A hydraulic retarder and no-load loss technology, applied in the direction of liquid resistance brakes, fluid pressure actuators, brake types, etc., can solve the problems of reduced work efficiency, large proportion, increased power loss, etc., to achieve Reduced contact area, reduced idling loss, and obvious effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

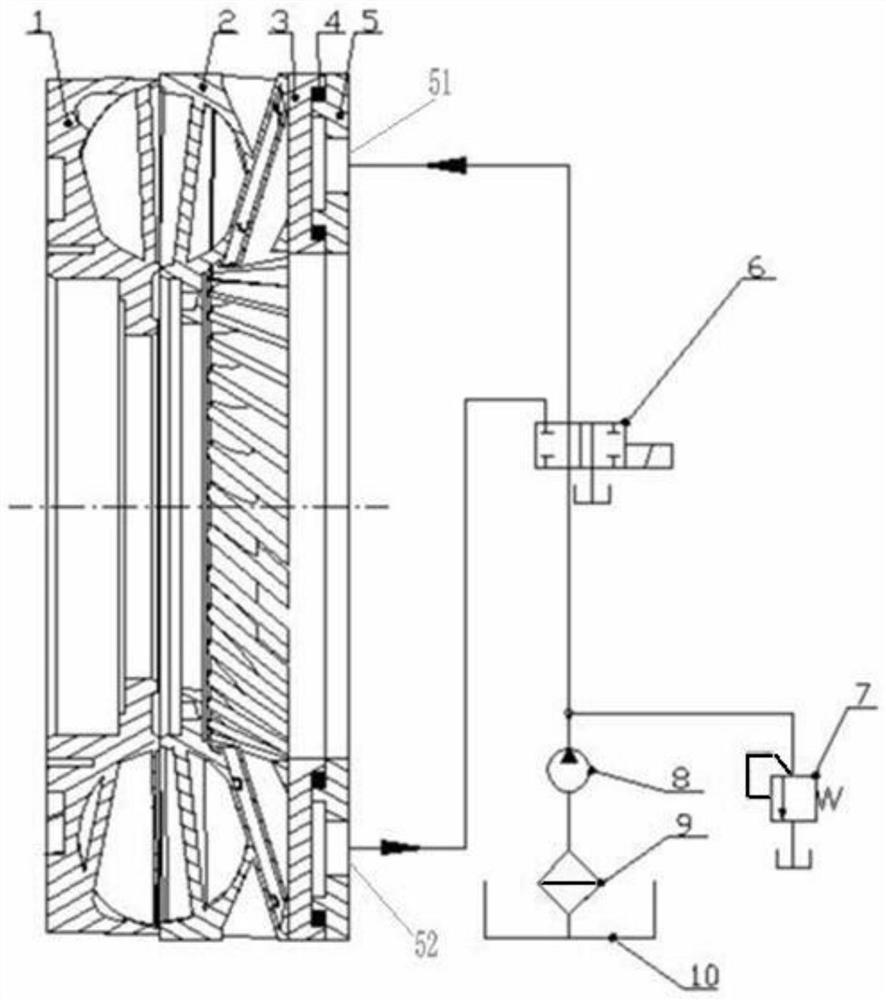

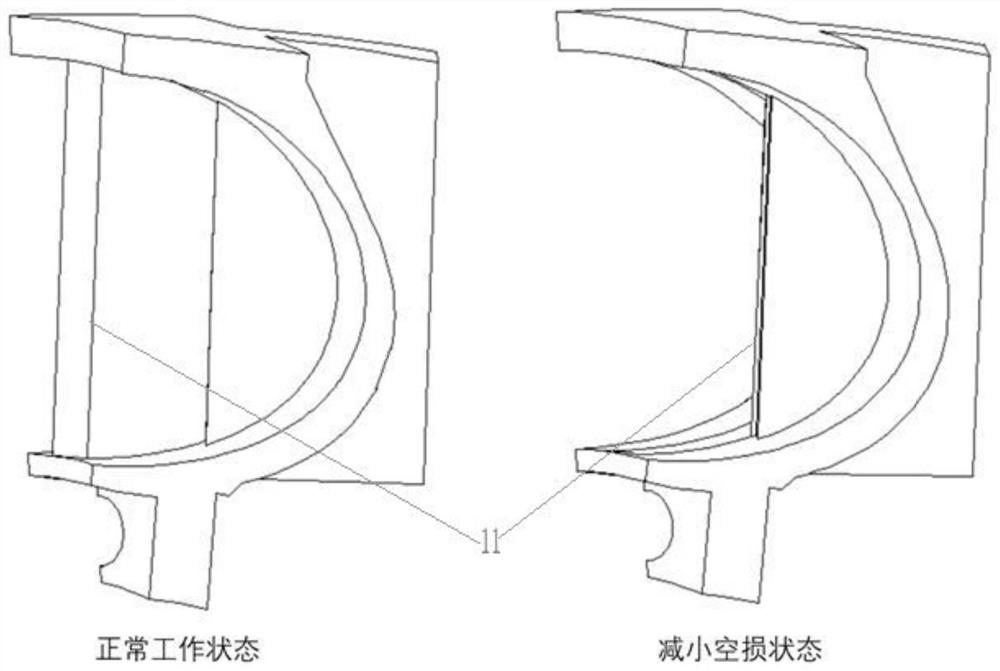

[0025] see Figure 1 to Figure 7 As shown, a hydraulic retarder with a rotor for reducing no-load loss includes a stator 1, a rotor 2, a first oil distribution mechanism 3, a sealing ring 4, a second oil distribution mechanism 5 and a hydraulic system, and the rotor 2 The first oil distributing mechanism 3 is fixedly arranged on the rotor 2, the second oil distributing mechanism 5 is rotatably arranged on the first oil distributing mechanism 3, the first oil distributing mechanism 3 and the second oil distributing mechanism 5 A sealing ring 4 is arranged between them, and the hydraulic system is connected with the second oil distribution mechanism 5;

[0026] Specifically, the first oil distribution mechanism 3 rotates synchronously with the rotor 2, and the second oil distribution mechanism 5 can rotate on the first oil distribution mechanism 3;

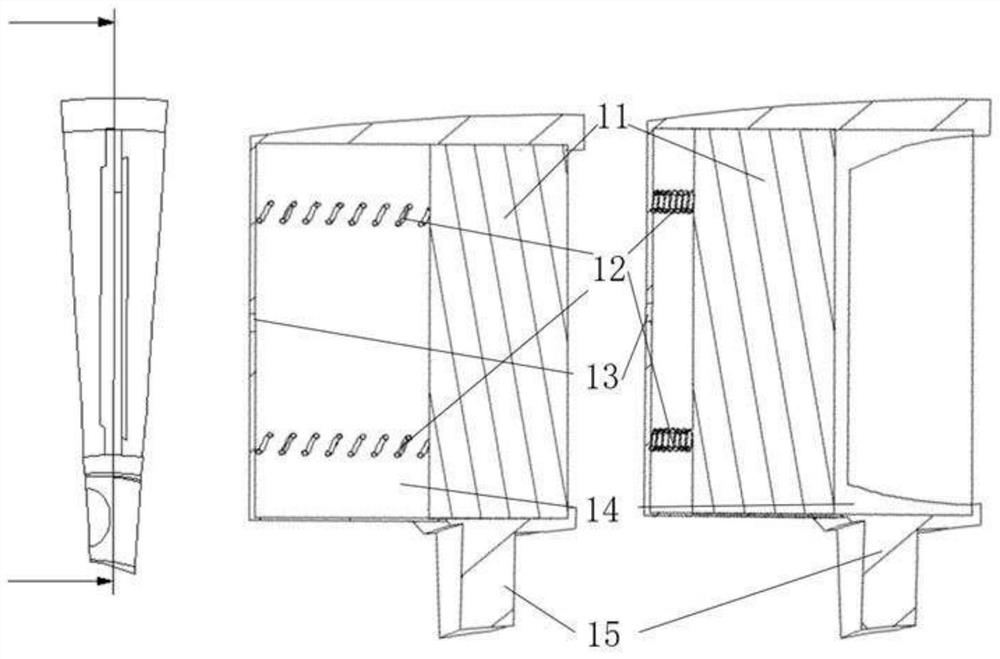

[0027] The rotor 2 is provided with an impeller, and several blade assemblies 16 are uniformly arranged on the impeller;

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com