Long-distance LNG unloading pipeline system and unloading method

A long-distance, unloading pipe technology, used in pipeline systems, container filling methods, pipeline protection, etc., can solve the problems of short service distance and difficult site selection, achieve less heat loss, increase conveying distance, and resistance loss. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

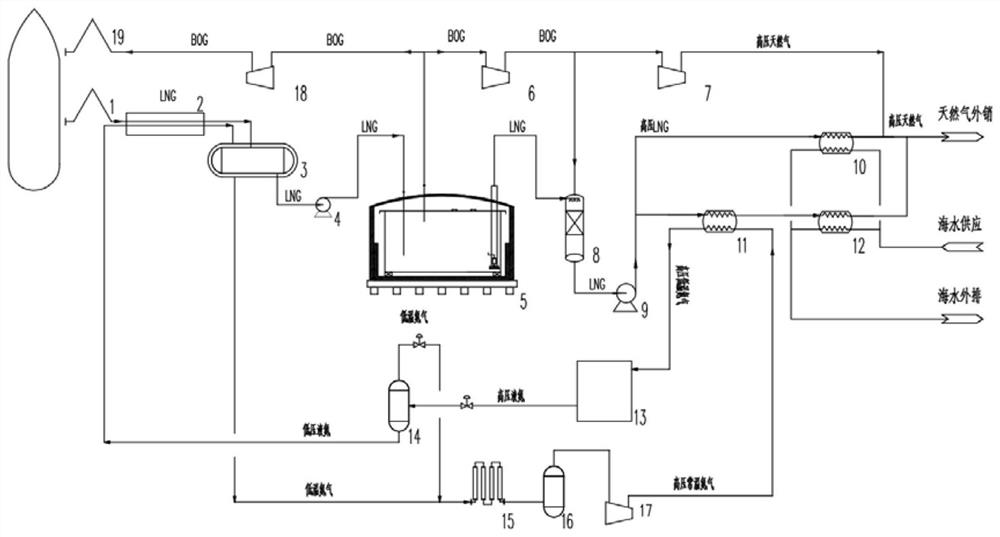

[0022] A long-distance LNG unloading pipeline system, such as figure 1 As shown, it includes: LNG discharge pipe 2, LNG buffer tank 3, secondary booster pump 4, LNG / nitrogen heat exchanger 11, nitrogen expansion refrigeration cycle system 13, liquid nitrogen storage tank 14, nitrogen air temperature heater 15 , nitrogen compressor suction tank 16 and nitrogen compressor 17 etc., wherein:

[0023] LNG unloading arm 1, LNG unloading pipe 2, LNG buffer tank 3, secondary booster pump 4, LNG storage tank 5, recondenser 8, LNG high-pressure output pump 9, LNG seawater vaporizer 10 are connected in sequence, LNG high-pressure output The pump 9, the LNG / nitrogen heat exchanger 11, and the low-temperature natural gas / seawater heat exchanger 12 are connected sequentially; the seawater supply is respectively connected to the LNG seawater vaporizer 10 and the low-temperature natural gas / seawater heat exchanger 12 before being discharged;

[0024] LNG storage tank 5, BOG compressor 6, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap