Self-walking substation personnel operation safety comprehensive monitoring system

A comprehensive monitoring system and comprehensive monitoring technology, applied in the direction of electric transmission signal system, radio wave measurement system, satellite radio beacon positioning system, etc., can solve the problems of scattered work sites, poor intelligence of the monitoring system, inconvenient use, etc., to achieve The effect of reducing the false alarm rate, reasonable design, and avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

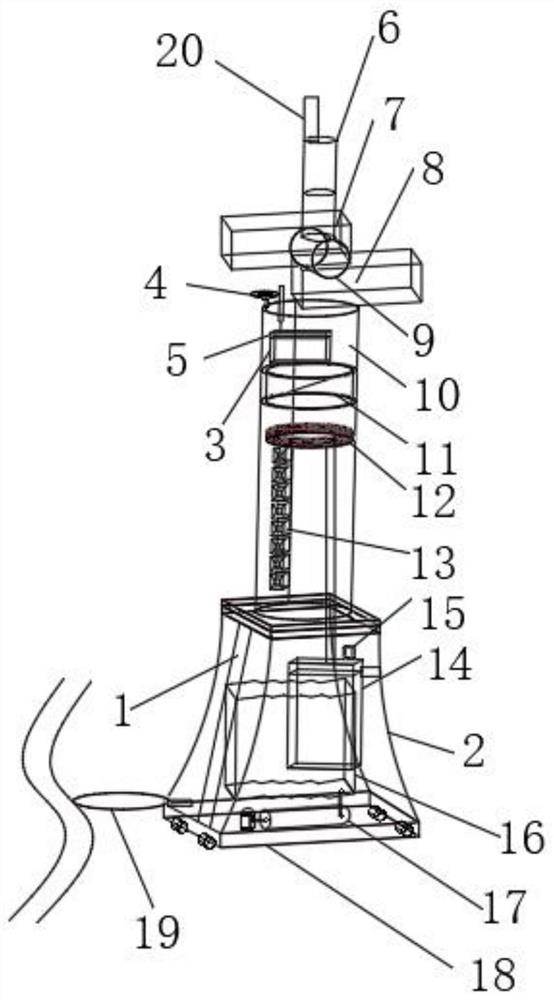

[0017] see figure 1 , a self-propelled substation personnel operation safety comprehensive monitoring system, including a comprehensive monitoring and alarm device 1, a monitor base 2, a monitor self-propelled chassis 18 and an anti-corrosion ground induction coil 19, the lower side of the comprehensive monitoring and alarm device 1 A monitor base 2 is fixedly installed, and the lower side of the monitor base 2 is fixedly connected with a monitor self-propelled chassis 18, and several anti-corrosion ground induction coils 19 are arranged inside the ground on the lower side of the monitor self-propelled chassis 18, The upper surface of the monitor base 2 is fixedly connected with a liftable rotating support tube 10, and the upper end side of the liftable rotating support tube 10 is fixedly connected with a camera multi-degree-of-freedom platform 9, and the camera multi-degree-of-freedom platform platform A high-definition identification camera 7 and an infrared temperature meas...

Embodiment 2

[0023] see figure 1 , a self-propelled substation personnel operation safety comprehensive monitoring system, including a comprehensive monitoring and alarm device 1, a monitor base 2, a monitor self-propelled chassis 18 and an anti-corrosion ground induction coil 19, the lower side of the comprehensive monitoring and alarm device 1 A monitor base 2 is fixedly installed, and the lower side of the monitor base 2 is fixedly connected with a monitor self-propelled chassis 18, and several anti-corrosion ground induction coils 19 are arranged inside the ground on the lower side of the monitor self-propelled chassis 18, The upper surface of the monitor base 2 is fixedly connected with a liftable rotating support tube 10, and the upper end side of the liftable rotating support tube 10 is fixedly connected with a camera multi-degree-of-freedom platform 9, and the camera multi-degree-of-freedom platform platform A high-definition identification camera 7 and an infrared temperature meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com