Excitation winding structure of exciter of brushless electro-magnetic starter generator, and starting/power generation switching method thereof

A starter generator and excitation winding technology, which is applied to the shape/style/structure of winding conductors, control generator, magnetic circuit shape/style/structure, etc. Problems such as low duty cycle of the switching tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

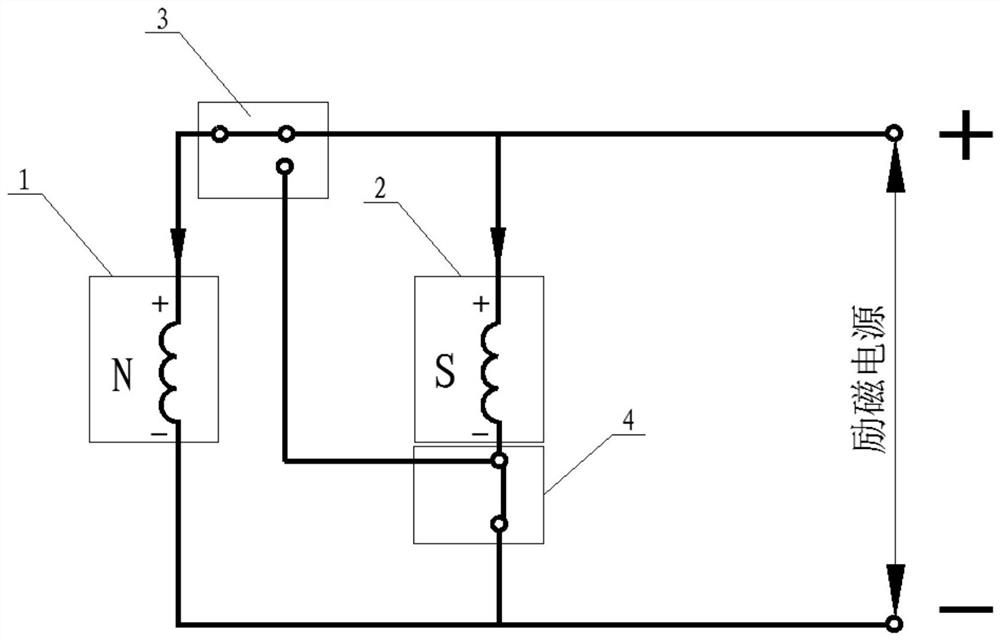

[0029] In this embodiment, a field winding and its starting / generating switching method that can change the winding series-parallel structure are proposed, so that the number of effective series turns of the exciting field winding of the exciter is reduced during starting, and the output capacity of the exciter is improved during starting. The number of effective series turns of the excitation winding of the exciter increases, so that the resistance of the excitation winding of the exciter increases, the excitation current decreases, and the excitation voltage increases.

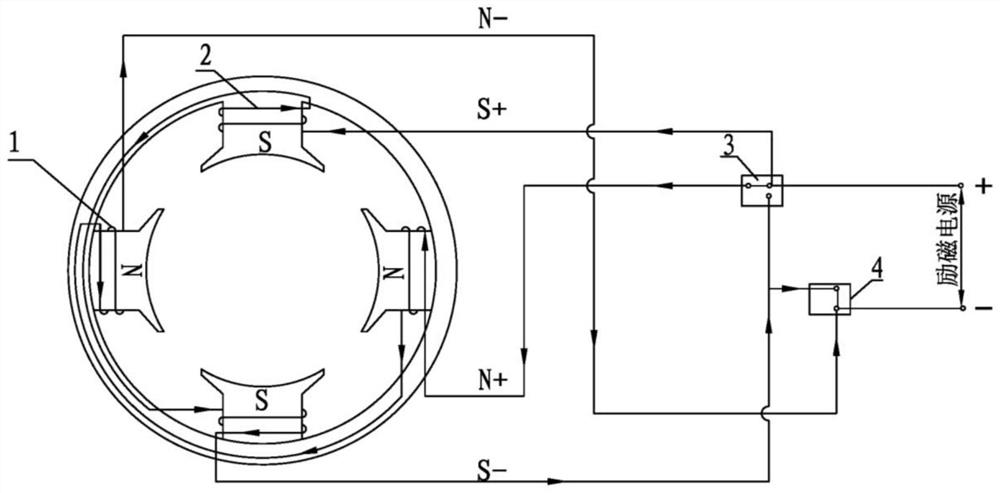

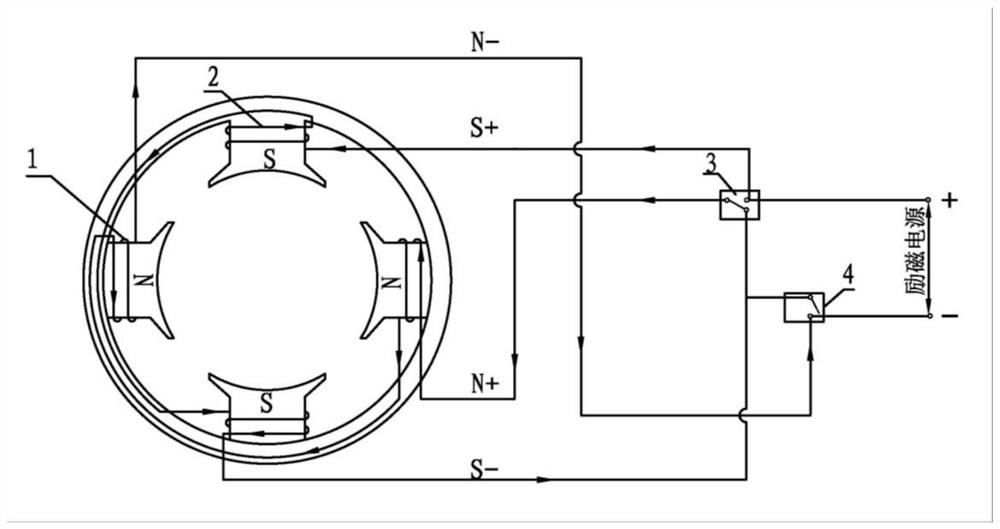

[0030] The exciter excitation winding structure of the brushless electric excitation starter generator includes an N pole winding 1 and an S pole winding 2 , a first contactor 3 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com