Rapid evaluation method for seepage rate of antifouling agent of antifouling paint

A technology of antifouling paint and evaluation method, applied in the direction of material inspection products, etc., can solve the problems of long test period of antifouling agent exudation rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

[0035] Step a, configure a special solution for soaking the sample, and add 40ml of NaOH solution (1.5mol / L), 3.95g of glycine, and 52g of NaCl in sequence in a 2L volumetric flask. After adding deionized water to constant volume, a soaking solution with a pH value of 11 is obtained;

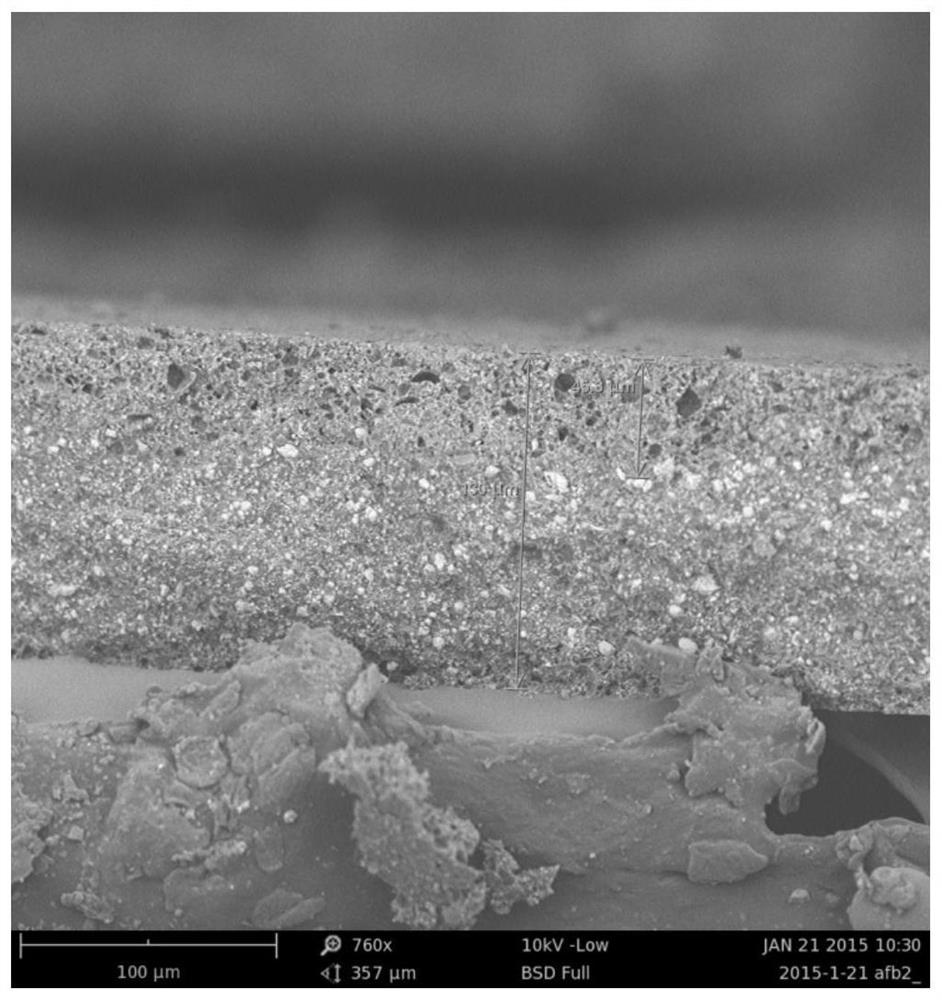

[0036] Step b. Brush the antifouling coating to be tested on the glass slide of the same specification, and use a 200μm specification wire bar coater to brush; after the sample is dried, obtain a copper ion exudation rate test with a dry film thickness of about 120μm Template;

[0037] Step c, add 50ml of buffer solution into a container that can be sealed, immerse all the test samples in the buffer solution, and seal the system;

[0038] Step d, after soaking for 48 hours, take a sampling test, take 5ml of liquid, dilute it 500 times, use a volumetric flask to constant volume, and use atomic absorption spectroscopy or high performance liquid chromatography to measure the copper ion concentrati...

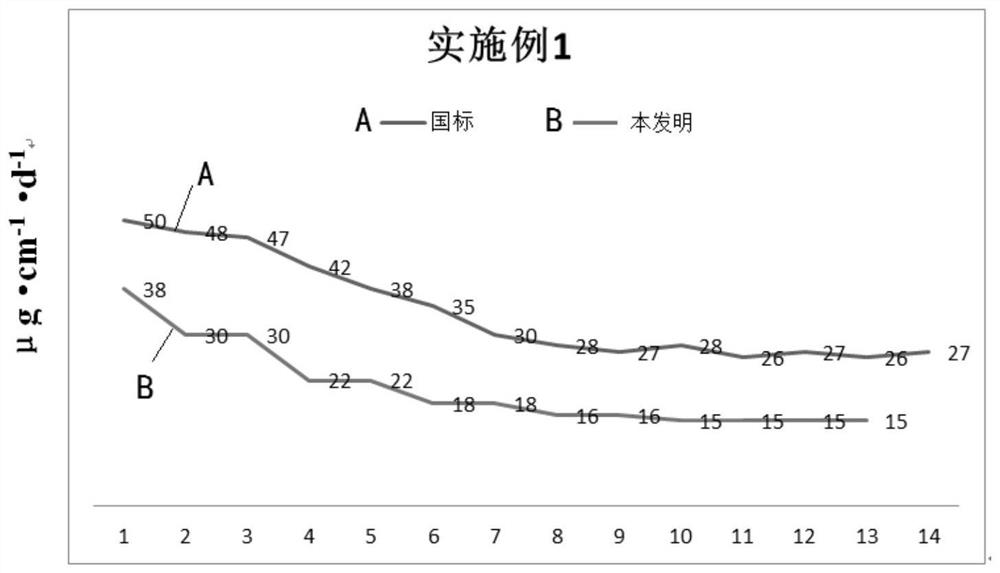

Embodiment 1

[0058] Tests on Dissolution Coating CDP-2:

[0059] Prepare the solution according to Example A, use a 200 μm specification wire bar coater to brush the antifouling paint on the common glass slide, and paint 3 groups of templates for each group of paint;

[0060] After the antifouling paint is dry, place the sample in a 50ml buffer solution container and seal it. After 48 hours, use a pipette gun to take out 5ml of the solution, add it to a 50ml volumetric flask, use deionized water to make up the volume (dilute 10 times), then use a pipette gun to take out 1ml of the solution in the volumetric flask, and add it to another 50ml volumetric flask , after constant volume with deionized water (diluted 50 times); use atomic absorption spectrometry to carry out copper ion concentration test (diluted 500 times) to the solution after dilution.

[0061] Repeat the above steps every 48 hours, and test 7 cycles and 14 days in total; obtain the copper ion exudation rate curve of the coat...

Embodiment 2

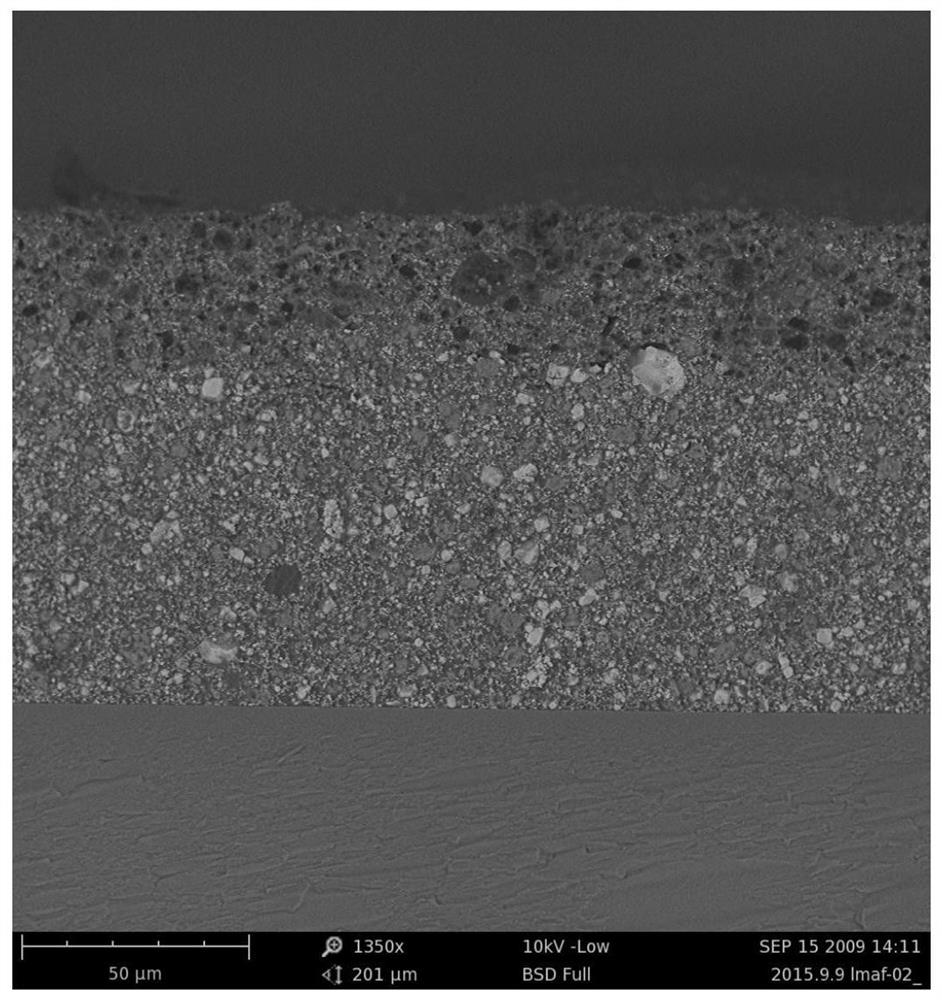

[0063] Testing of self-polishing coating SPC-7:

[0064] Prepare the solution according to Example A, use a 200 μm wire bar coater to brush the antifouling paint on the ordinary glass slide, and paint 3 groups of samples for each group of paint.

[0065] After the antifouling paint is dry, place the sample in a 50ml buffer solution container and seal it. After 48 hours, use a pipette gun to take out 5ml of the solution, add it to a 50ml volumetric flask, use deionized water to make up the volume (dilute 10 times), then use a pipette gun to take out 1ml of the solution in the volumetric flask, and add it to another 50ml volumetric flask , after constant volume with deionized water (diluted 50 times); use atomic absorption spectrometry to carry out copper ion concentration test (diluted 500 times) to the solution after dilution.

[0066] Repeat the above steps every 48 hours for a total of 7 cycles and 14 days of testing. The copper ion exudation rate curve of the coating is o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com