Edge cutting device and method for end socket without turnup

A head and flanging technology, which is applied in the field of head edge cutting devices, can solve problems such as the inability to accurately determine the head cutting edge height, low production efficiency, and difficulty in meeting the technical requirements of the head quality, so as to improve market competitiveness, Improve efficiency and meet quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

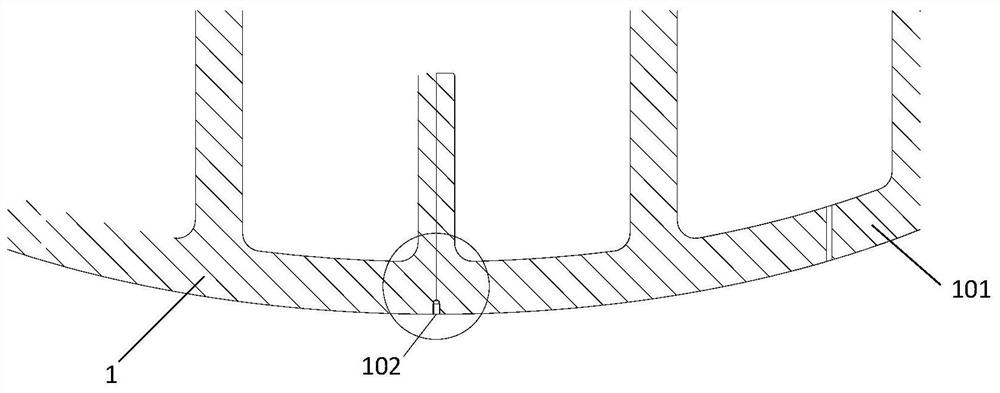

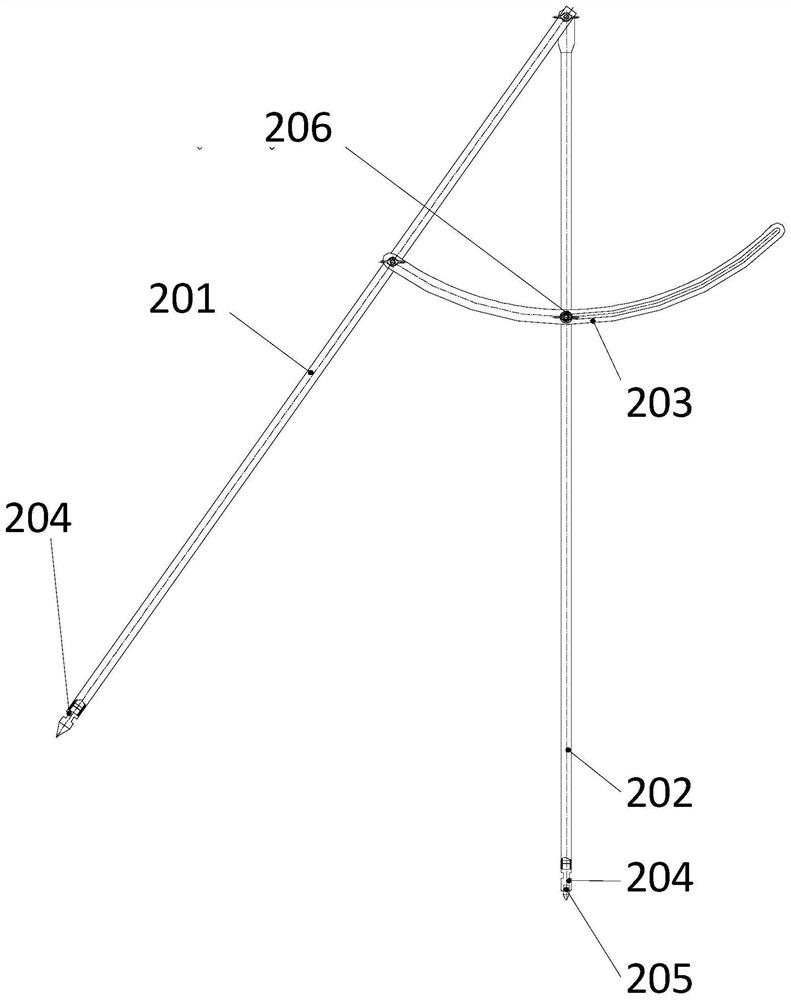

[0050] The invention provides a head edge cutting device without flanging, the specific structure of which includes an automatic centering head punch 1, a tool for cutting and marking the inner surface of the head 2, and turning the inner surface line of the head to the outer surface line Tooling 3; the automatic centering head punch 1 includes a head punch 101 and an automatic centering structure 102 arranged at the center of the head punch 101, and the head punch 101 is used to press the head blank to form The sealing head 4 , the automatic centering structure 102 is used to mark the center of the sealing head 4 .

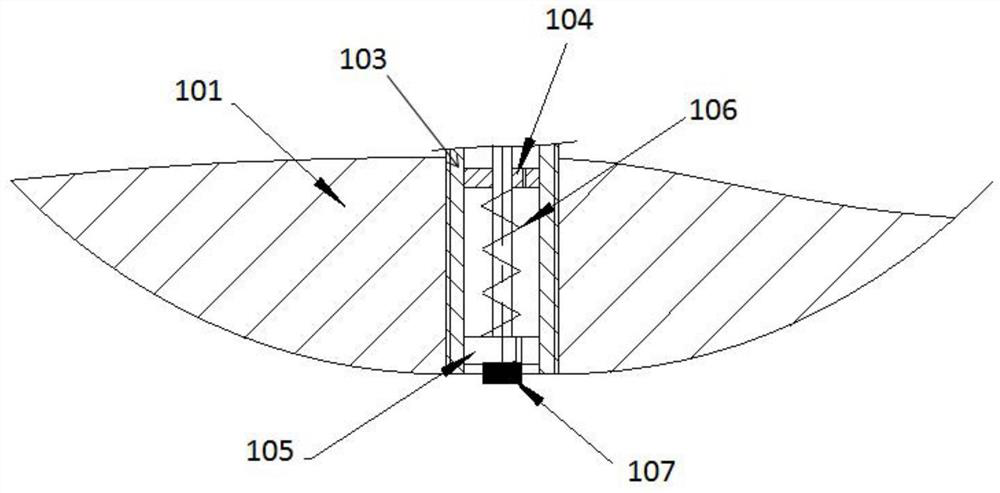

[0051]The automatic centering head punch 1 includes a head punch 101 and an automatic centering structure 102; the center of the head punch 101 is provided with a threaded through hole of M12*25; the automatic centering structure 102 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com