Punching die waste discharging mechanism and punching die thereof

A punching die and waste technology, applied in the direction of punching tools, manufacturing tools, forming tools, etc., can solve the problems of inability to effectively prolong the service life of punching, cumbersome replacement of punching worktables, protection of punches and punching dies, etc. The effect of reducing the risk of fracture failure, increasing service life and reducing fatigue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

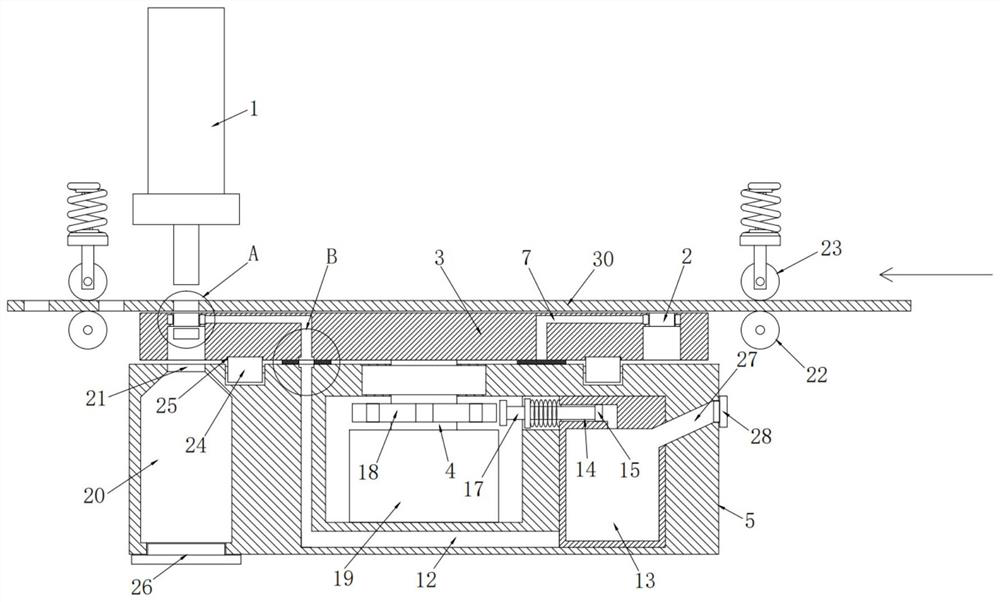

[0028] see Figure 1-7 , the present invention provides a technical solution:

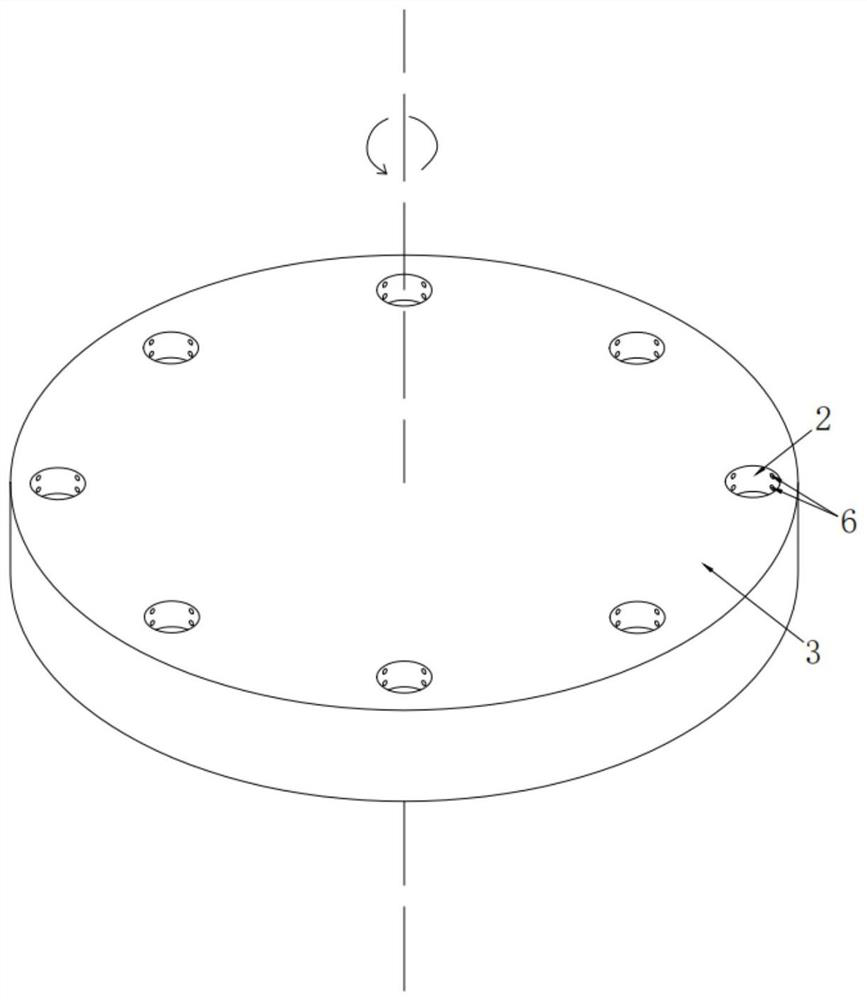

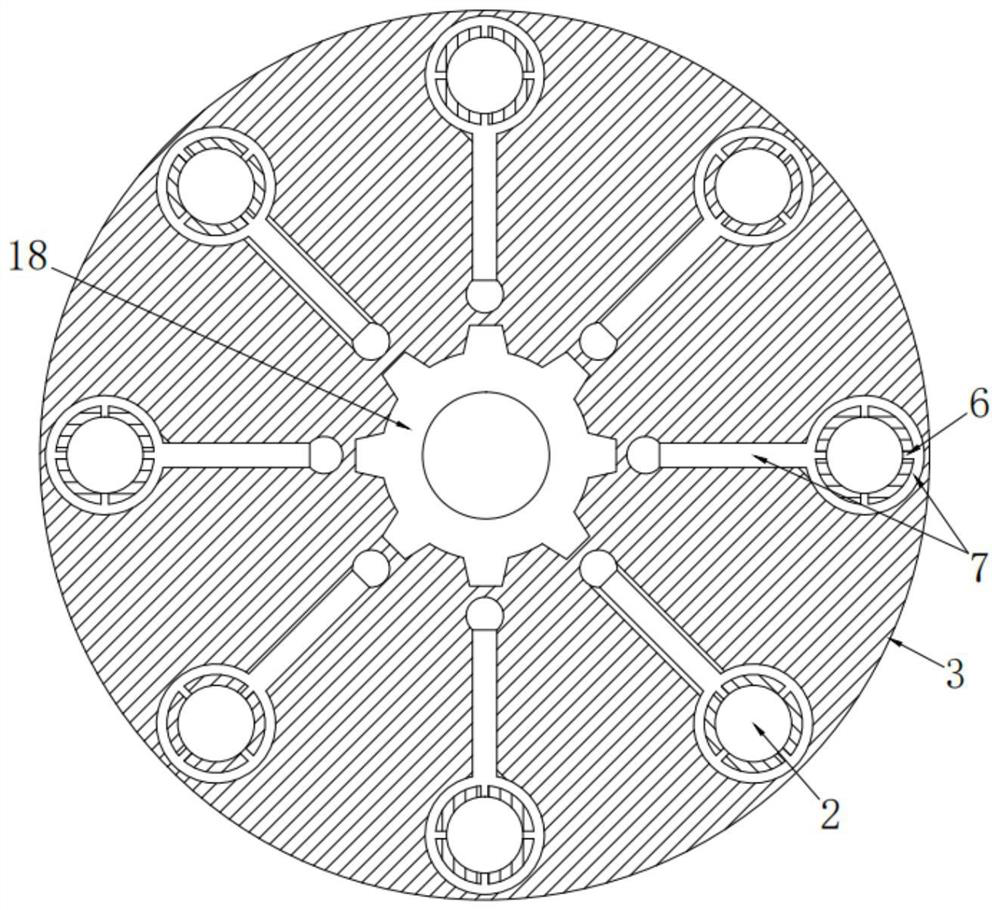

[0029] A stamping die waste discharge mechanism and its stamping die, including a punch 1, the punch 1 cooperates with several discharge holes 2 intermittently, and the punch 1 cooperates with the discharge holes 2 to punch holes in the punching continuous conveying parts 30 , a number of discharge holes 2 are arranged in a circular array on the rotary table 3, and the rotation of the rotary table 3 makes the different discharge holes 2 cooperate with the punch 1 in turn, and the rotary table 3 is installed on the discharge fixed by the rotating shaft 4. On the seat 5, the rotation of the rotary table 3 is driven by the rotation of the rotating shaft 4;

[0030] There are stamping oil release holes 6 in several discharge holes 2, and the stamping oil release holes 6 communicate with the oil inlet hole 8 at the far end through the oil supply channel 7 opened in the rotary table 3, and the oil inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com