Method for pouring rectangular blank through clamping-free section of R10-meter-arc continuous casting machine

A technology of continuous casting machine and rectangular billet, which is applied in the field of casting rectangular billet without clamping section of R10 meter arc continuous casting machine, which can solve the problems of high cost and complicated installation of clamping section, so as to reduce operation and maintenance cost and promote stable production Sex and process productivity, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

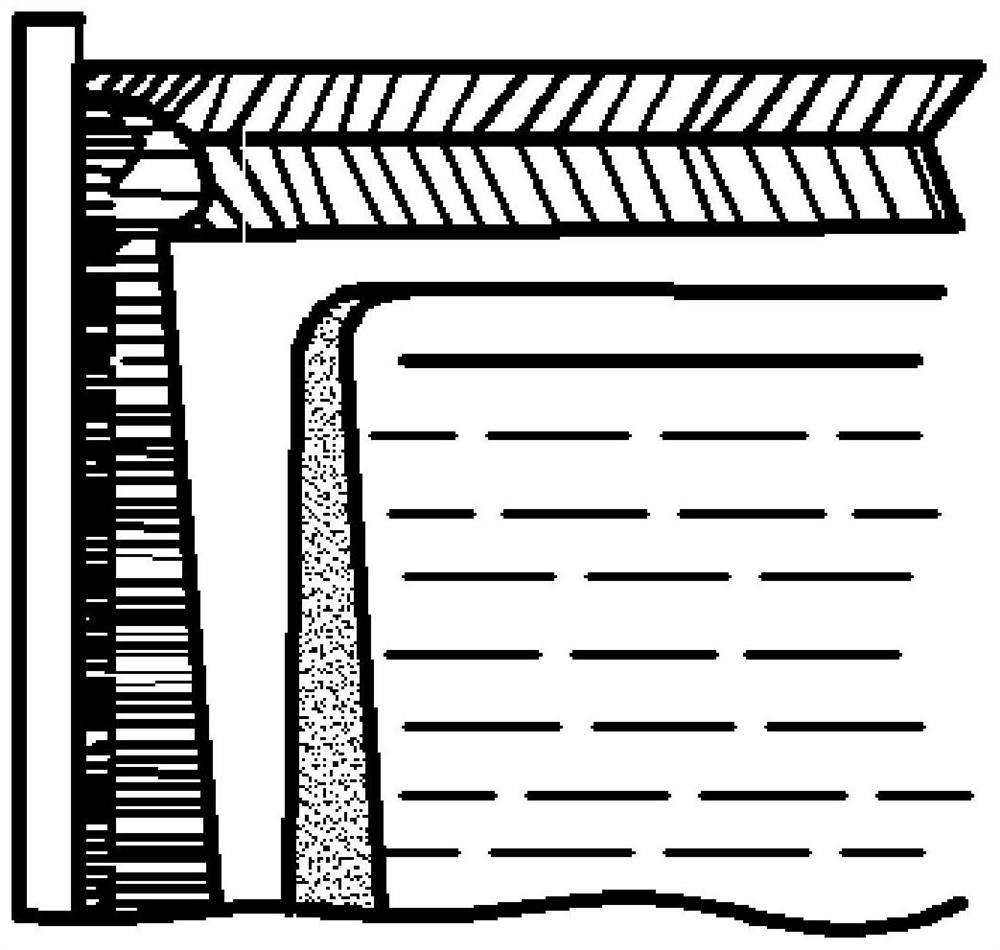

[0041] Optimize the reverse taper curve of the arc surface and straight surface of the mold copper tube, control the gap between the shell of the primary continuous casting billet and the copper tube, and increase the safe thickness of the billet shell after the mold is raised. The casting speed of the continuous casting billet in step 2 is 1.6 -2.0m / min.

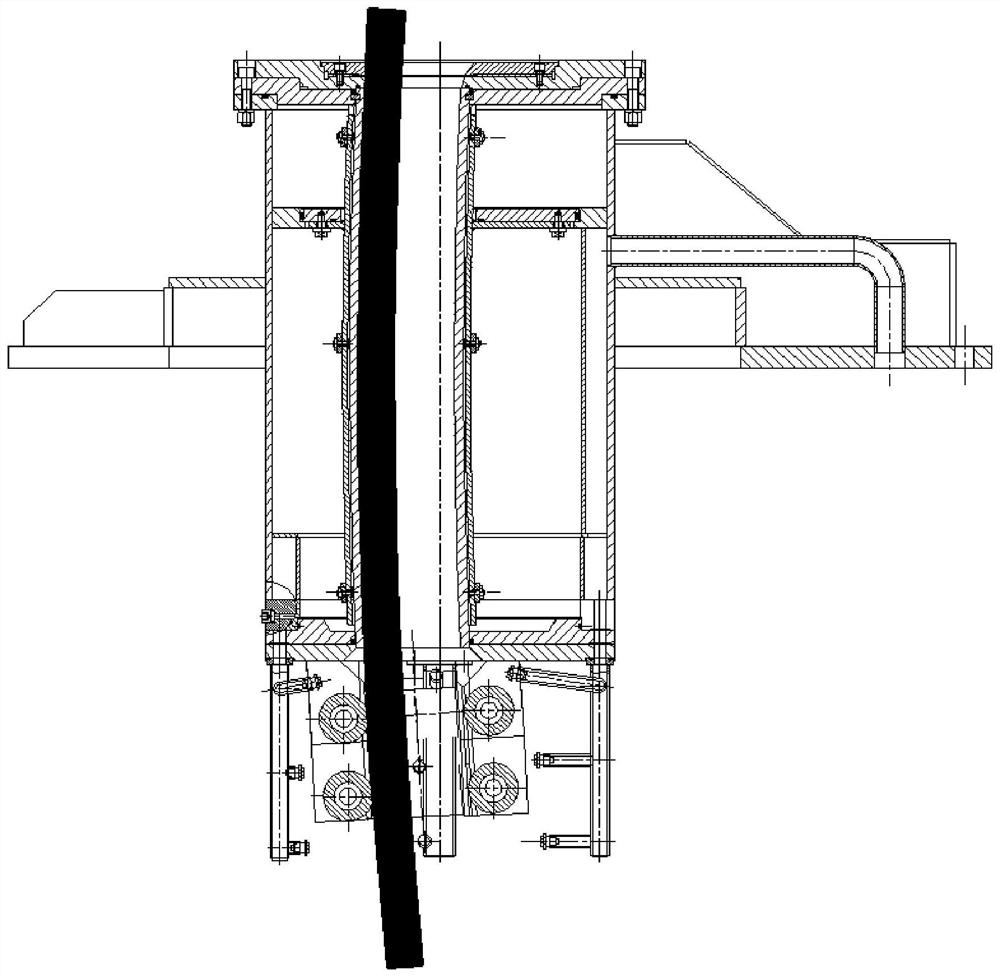

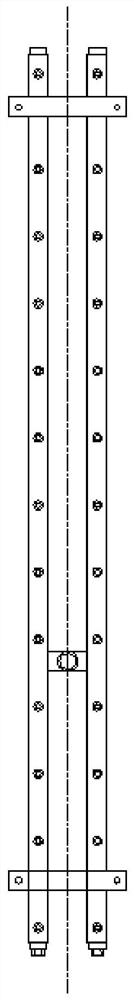

[0042] Use the R10 meter arc special calibration template to adjust the gap between the foot roller and the calibration template; the gap between the foot roller and the calibration template in step 3 is 0.0mm-0.5mm. Ensure that the continuous casting slab is supported by the foot roll when it enters the secondary cooling zero section during the pouring process to reduce the deformation of the wide surface of the continuous casting slab, such as figure 1 shown.

[0043] The melting temperature of the mold flux is 1170-1180°C, the viscosity of the mold flux is 0.70-0.73Pa.S, the alkalinity of the flux is 0.88-0.92 for perit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com