Clamp for taking out cylindrical sample after pilot test of hydraulic oil in triaxial pressure chamber and use method

A pressure chamber and hydraulic oil technology, used in the manufacture of tools, pliers, etc., can solve the problem of inconvenient removal of cylindrical samples, achieve the effects of light weight, ensure reliability, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

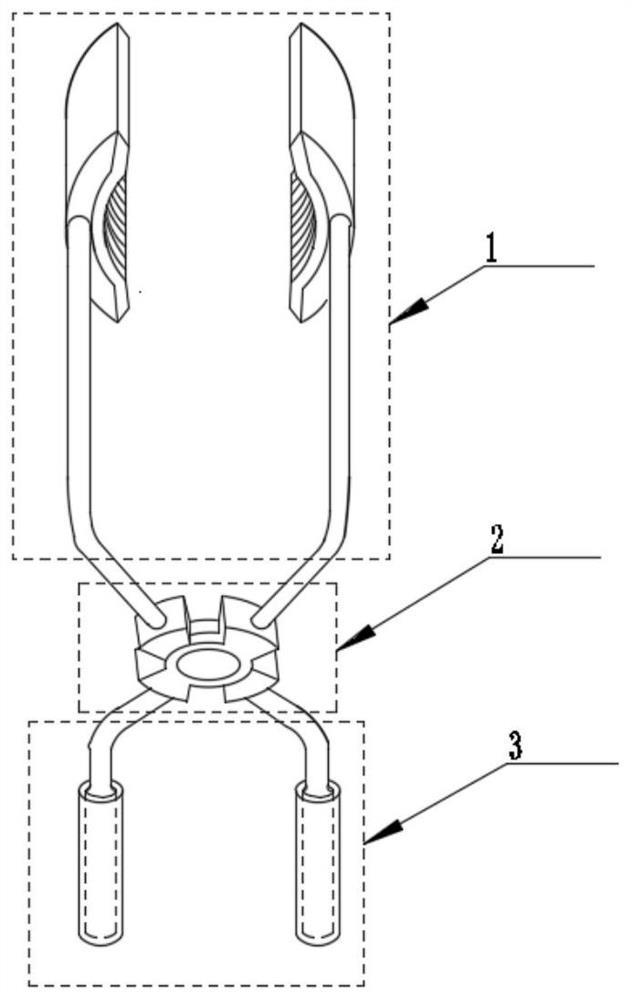

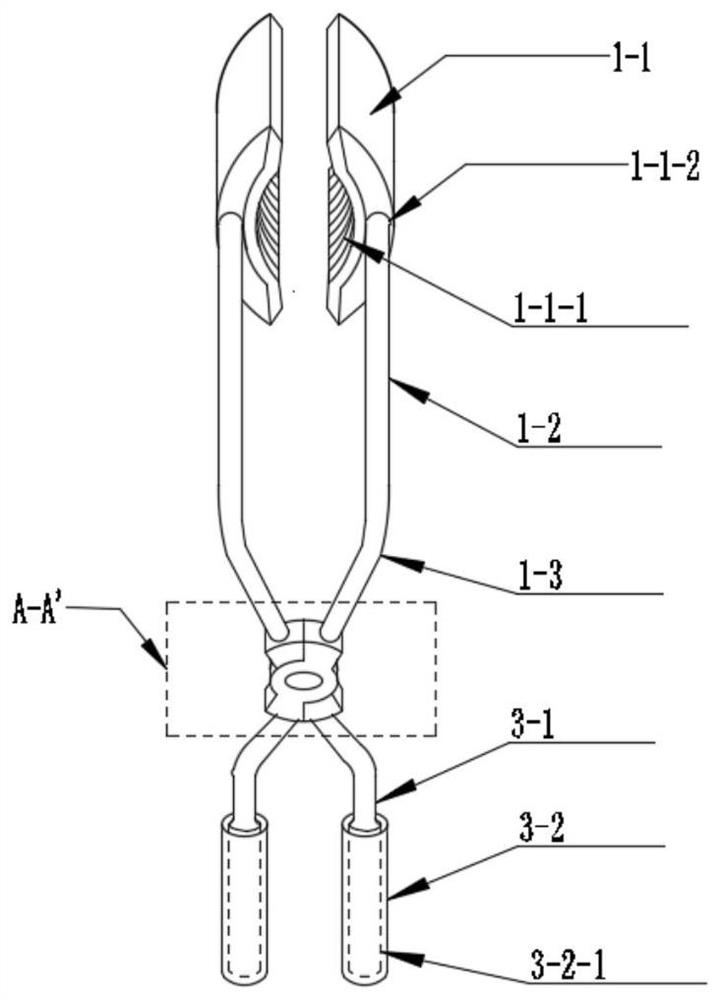

[0044]A jig for taking out a cylindrical sample after a pilot test of hydraulic oil in a triaxial pressure chamber, including two clamping parts and a fixed bolt 2-3, each clamping part includes a clamp arm section 1, a central connecting piece 2 and a fixed connection in sequence. The handle section 3, the central connectors 2 of the two clamping parts are connected by the fixed bolt 2-3, so that the two central connectors 2 can rotate around the fixed bolt in the plane where they are located, and the clamp arm section 1 It includes a clamping handle 1-1, a first connecting rod 1-2 and a second connecting rod 1-3 connected in sequence, the inner wall of the clamping handle 1-1 is an active surface for clamping the cylindrical shape, two The clamping handle 1-1 of the clamping part is relatively embracing the cylindrical shape, and the clamping handle 1-1 is fixed on the end of the first connecting rod 1-2, and the first connecting rod 1-2 and the second connecting rod 1-2 The...

Embodiment 2

[0048] The method of using the clamp for taking out the cylindrical sample after the pilot test of the hydraulic oil in the triaxial pressure chamber includes the following steps:

[0049] Step 1. Shake the grip section 3 with both hands, and open and close left and right to ensure that the central connector 2 of the fixture can move freely;

[0050] Step 2. Keep the clamping handle 1-1 in the fully open state and penetrate below 1 / 2 of the depth of the pressure chamber. At this time, keep the vertical position unchanged. Slowly adjust the holding section 3 with both hands to reduce the distance between the two clamping handles 1-1. Distance, when the clamping handle 1-1 touches the cylindrical sample, the grip section 3 of the two hands is slowly moved closer until it is tightened, and gently pulled, after confirming that it is safe, the cylindrical sample is put out to the sample tray at one time;

[0051] Step 3, hang the clamp on the upper port of the pressure chamber, the...

Embodiment 3

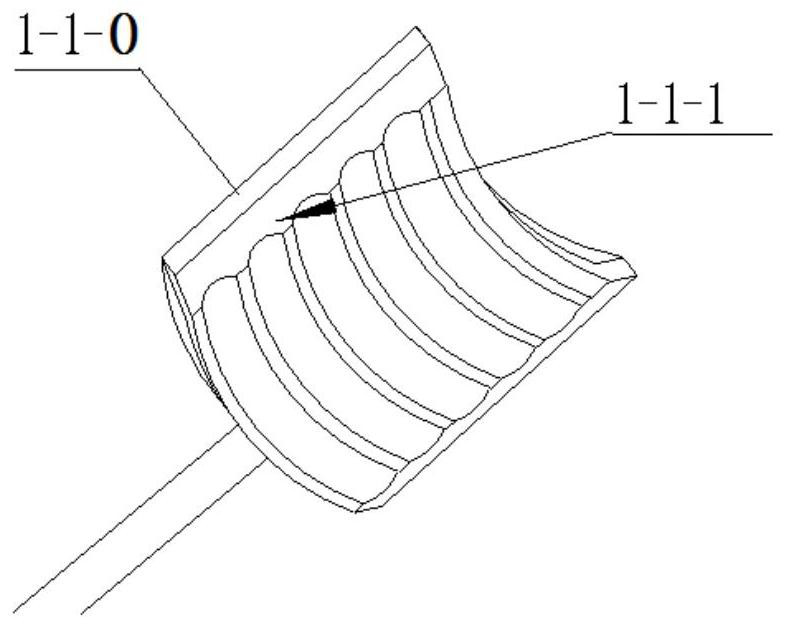

[0054] In order to improve the stability of clamping, the clamping handle 1-1 includes a metal arc-shaped plate 1-1-0 and a rubber pad 1-1-1 closely fitted and fixed on the inner wall of the arc-shaped plate. The surface of the rubber pad 1-1-1 is the working surface, and the convex-concave texture is formed on the working surface. Preferably, the convex-concave texture is composed of arc-shaped grooves and planar protrusions arranged at intervals, the concave part is arc-shaped, and the surface of the raised part is plane. The rubber pad with low temperature resistance, oil corrosion resistance and ductility can Buffer clamping force, the rubber pad contacting the cylindrical sample surface has a convex-concave texture to enhance the friction with the sample surface during the clamping process and prevent slipping during the clamping process. When the hydraulic oil is in the air, the hydraulic oil attached to the rubber pad quickly flows into the pressure chamber along the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com