Vehicle seat

A seat and vehicle technology, applied in other seating furniture, seats, applications, etc., can solve problems such as insufficient ventilation, large deformation, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

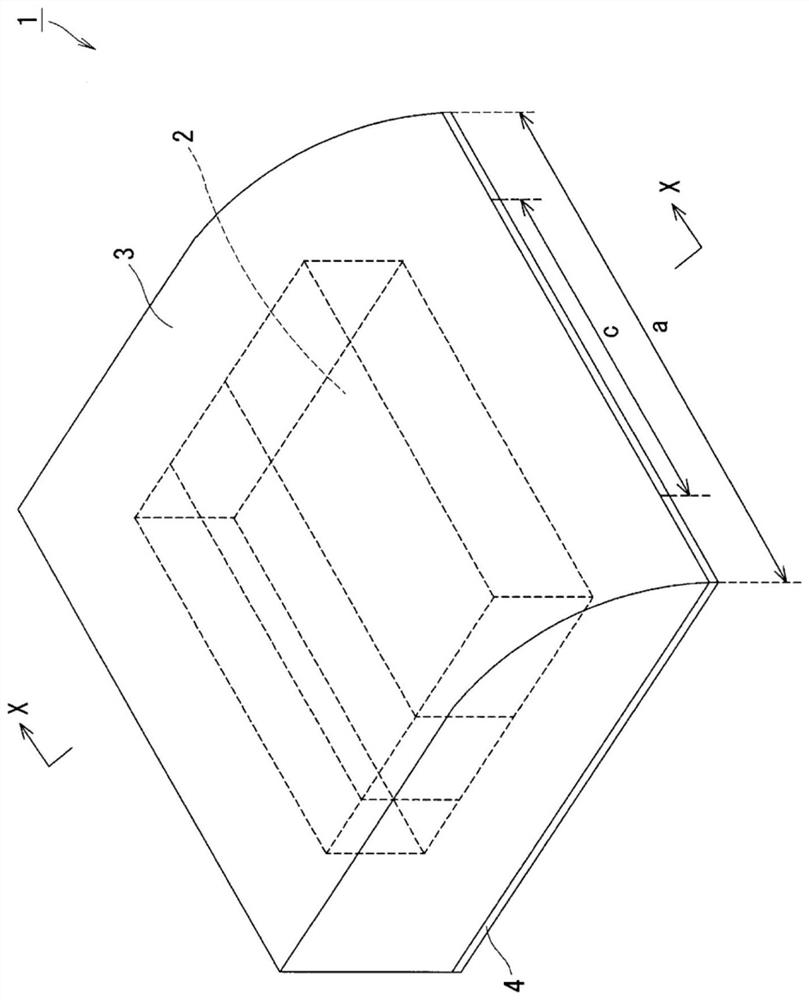

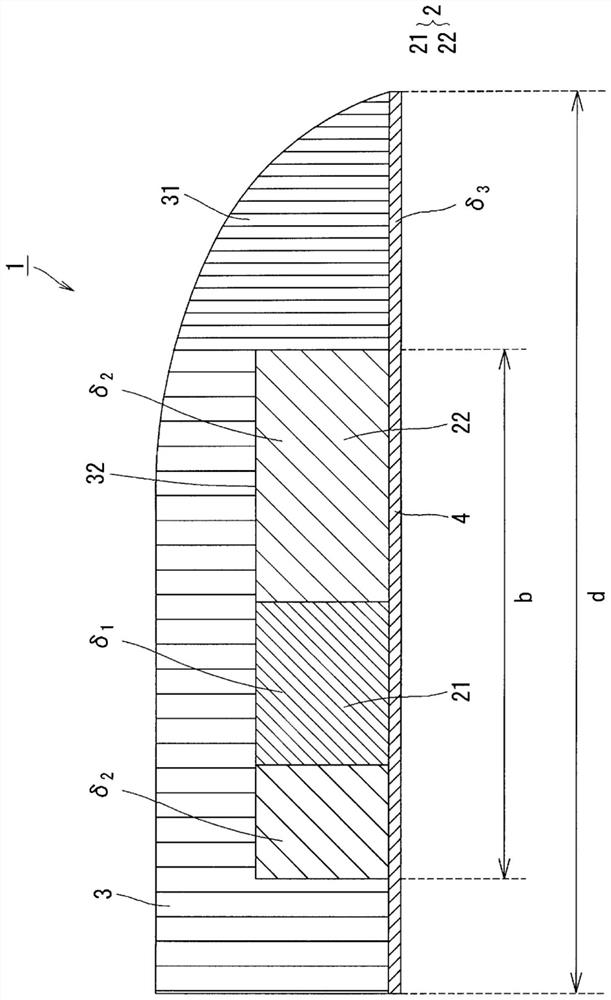

[0032] refer to Figure 1 ~ Figure 2 The vehicle seat 1 according to the first embodiment of the present invention will be described. The vehicle seat 1 includes: a three-dimensional mesh structure 2 serving as a first cushioning body; a vertical nonwoven fabric 3 serving as a second cushioning body laminated and arranged above the first cushioning body; and a spring receiving member. 4. The longitudinal nonwoven fabric 3 has a shape in which the thickness becomes thinner in the front region. In the groove portion 32 formed on the lower surface of the vertical nonwoven fabric 3, a three-dimensional network structure 2 having the same shape as the groove portion 32 is fitted so as to be compatible with the three-dimensional network structure 2 and the vertical nonwoven fabric 3. The spring receiving member 4 is arranged so that the lower surface abuts on it, and the whole thereof is covered with a cover (not shown) made of cotton cloth, non-woven fabric, or the like.

[0033...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com