Pattern random dyeing regulation and control method for three-component chenille carpetpile

A chenille and three-component technology, applied in the field of spinning chromatography, can solve the problems of inability to dye to achieve color matching, patchwork, clipping, lack of research, etc., to achieve the effect of enriching expressiveness and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

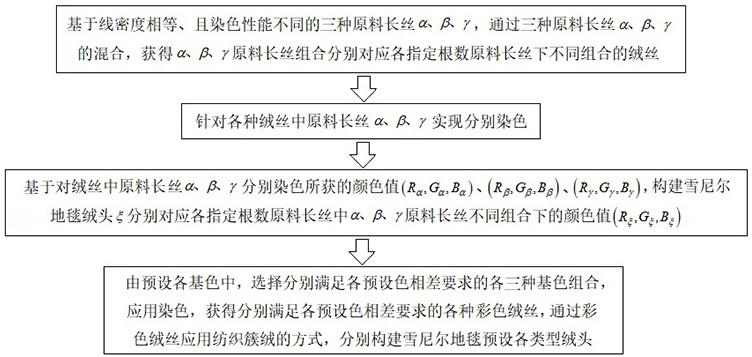

[0039] The present invention designs a kind of three-component chenille carpet pile pattern random dyeing control method, in the middle of practical application, such as figure 1 As shown, the following steps A to D are specifically performed.

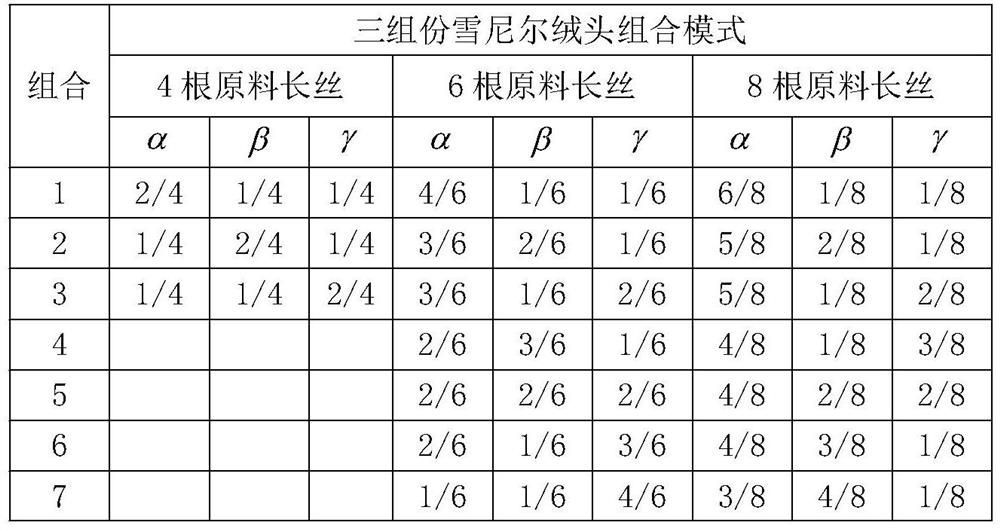

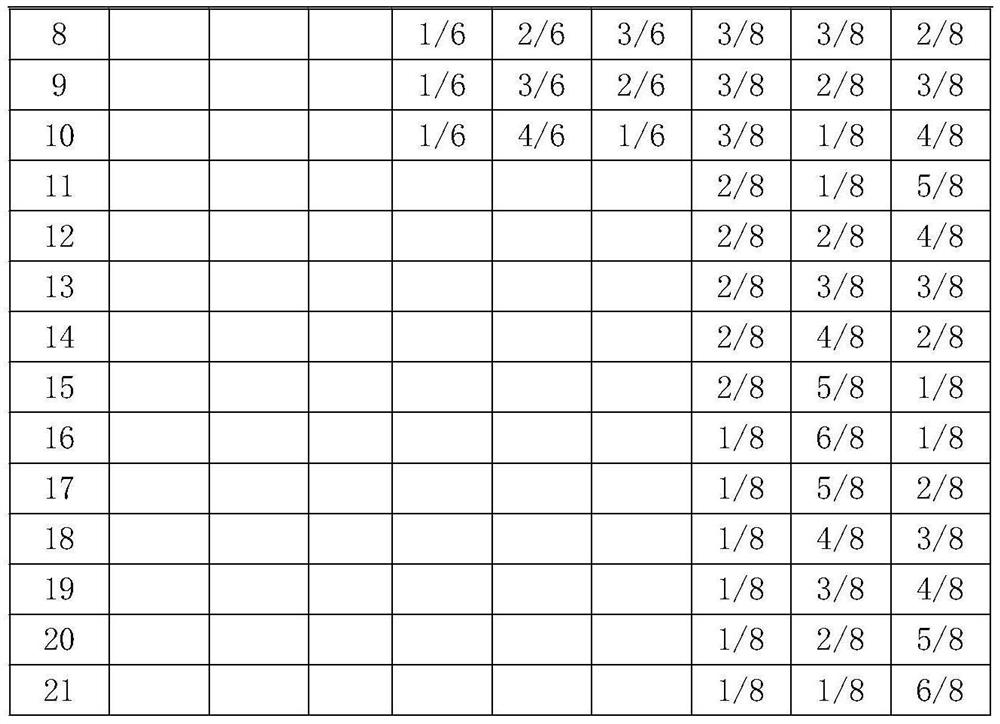

[0040] Step A. Based on three raw material filaments α, β, γ with equal linear density and different dyeing properties, such as polyester filament, cationic dyeable polyester filament, nylon filament, cationic modified viscose filament, viscose Filament, acrylic filament, cationic dyeable acrylic filament, etc., as shown in Table 1 below:

[0041] Table 1

[0042]

[0043]

[0044] Through multiple combinations and gradient ratios, the three kinds of raw material filaments α, β, and γ are mixed, and the combination of α, β, and γ raw material filaments respectively corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com