An assembled steel plate combined energy-dissipating shear wall

A shear wall and prefabricated technology, which is applied to walls, passive houses, protective buildings/shelters, etc., can solve the problems of complex construction, difficult technical connection form, easy to damage prefabricated shear walls, etc., to achieve convenient The effect of small vibration, maintaining the degree of deformation, and reducing the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail by specific embodiments:

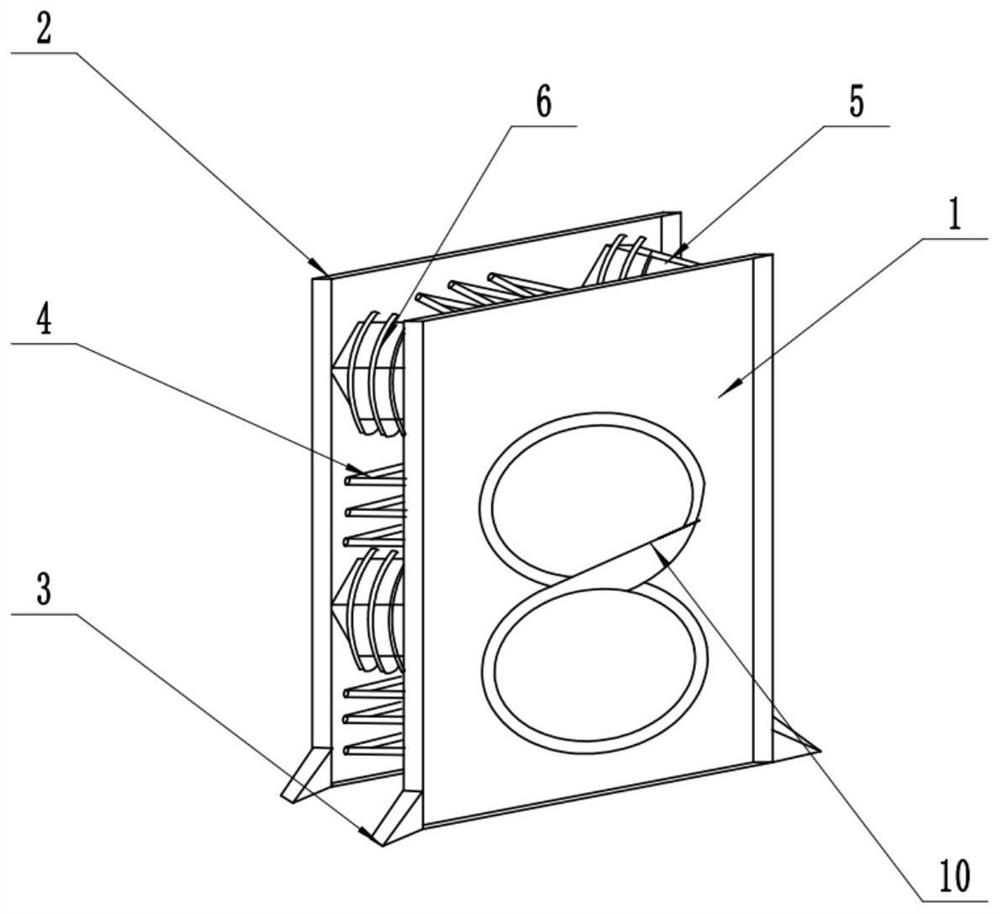

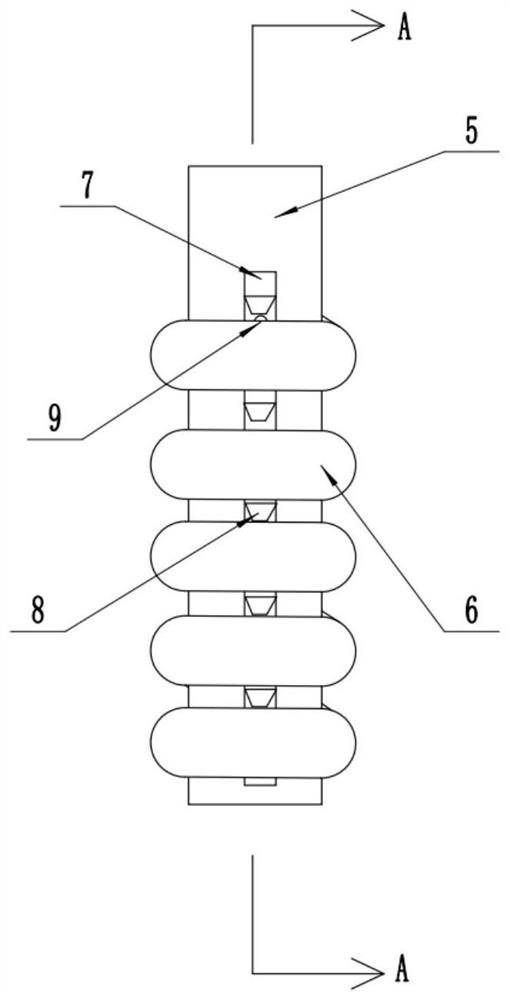

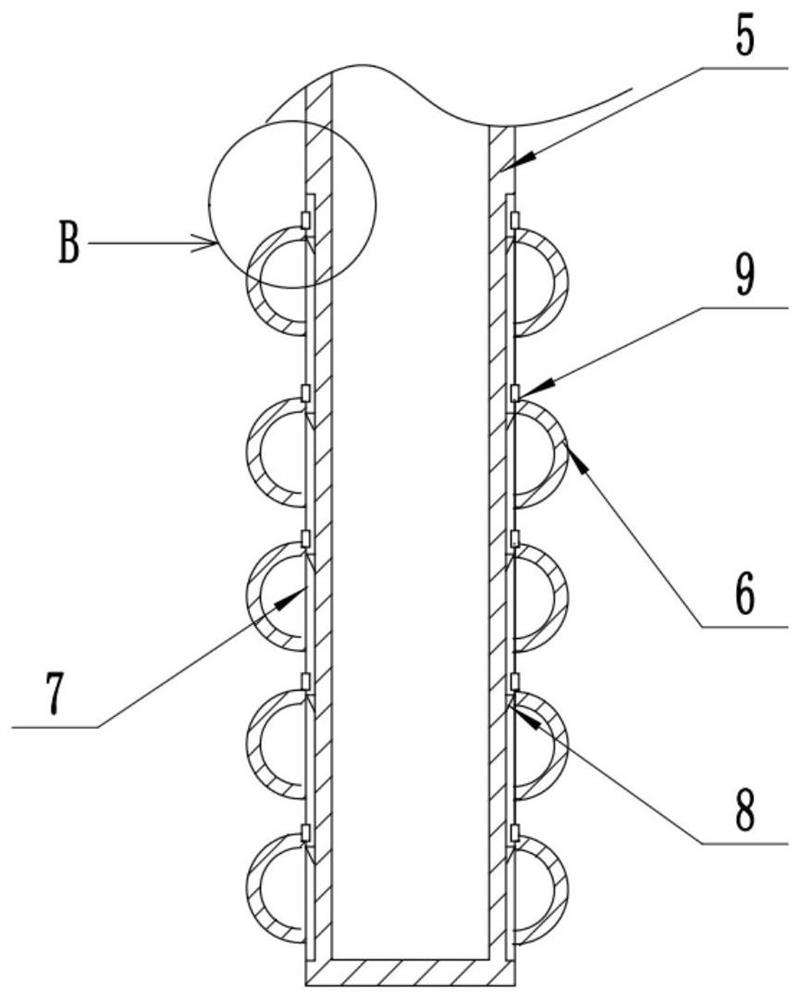

[0029] Reference numerals in the accompanying drawings include: first prefabricated wall 1, second prefabricated wall 2, pullout anchor bolts 3, distribution steel bars 4, bearing columns 5, curved steel bars 6, chute 7, wedge-shaped block 8, convex block 9. Slot 10.

[0030] The example is basically as attached figure 1 and figure 2 , shown: a prefabricated steel plate composite energy-dissipating shear wall includes a first prefabricated wall 1 and a second prefabricated wall 2, the radial sides of the first prefabricated wall 1 and the second prefabricated wall 2 are provided with pull-out anchors Bolt 3, the first prefabricated wall 1 and the second prefabricated wall 2 are connected with distribution steel bars 4 and several bearing columns 5, the circumferential direction of the bearing columns 5 is wrapped with curved steel bars 6, and the distribution steel bars are interspersed between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com