A Perforated Yield Energy Dissipator

A technology of energy consumers and connecting holes, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of inconvenient installation and replacement, complex structure, etc., and achieve convenient disassembly and maintenance and low energy consumption. Mechanism is clear and the effect of improving energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

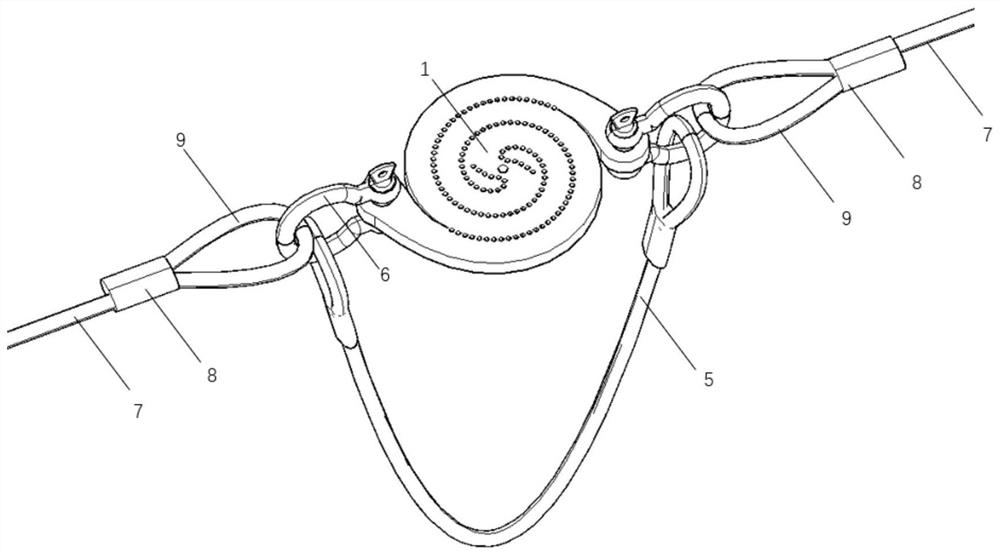

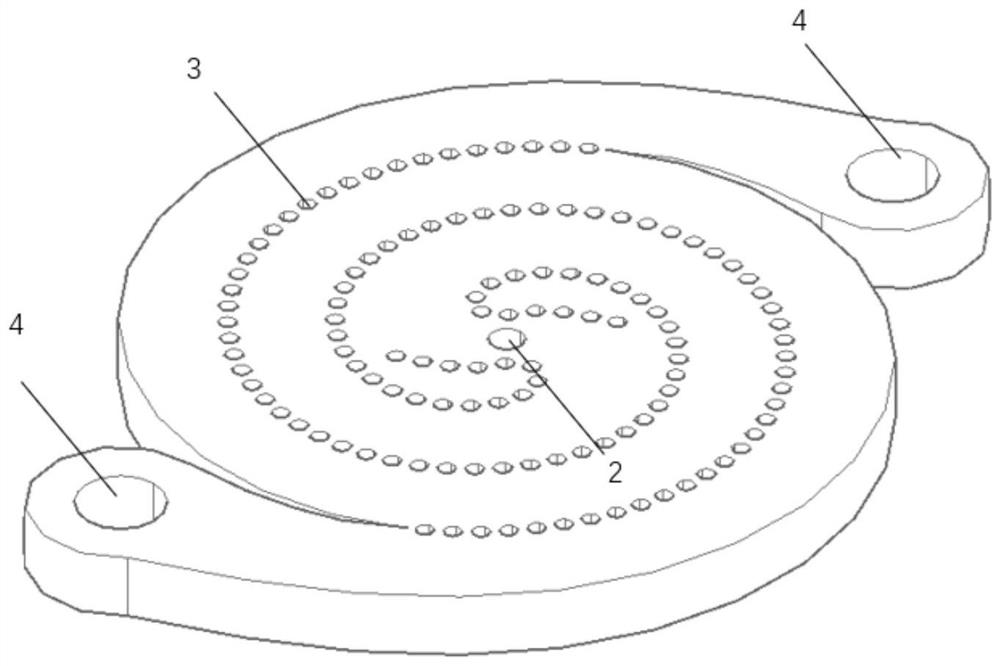

[0063] like figure 2 Shown, a design method for a perforated yield-type energy dissipator. When used alone, the energy dissipator includes a metal plate 1 with a hole, a protection rope 5 and two shackles 6 .

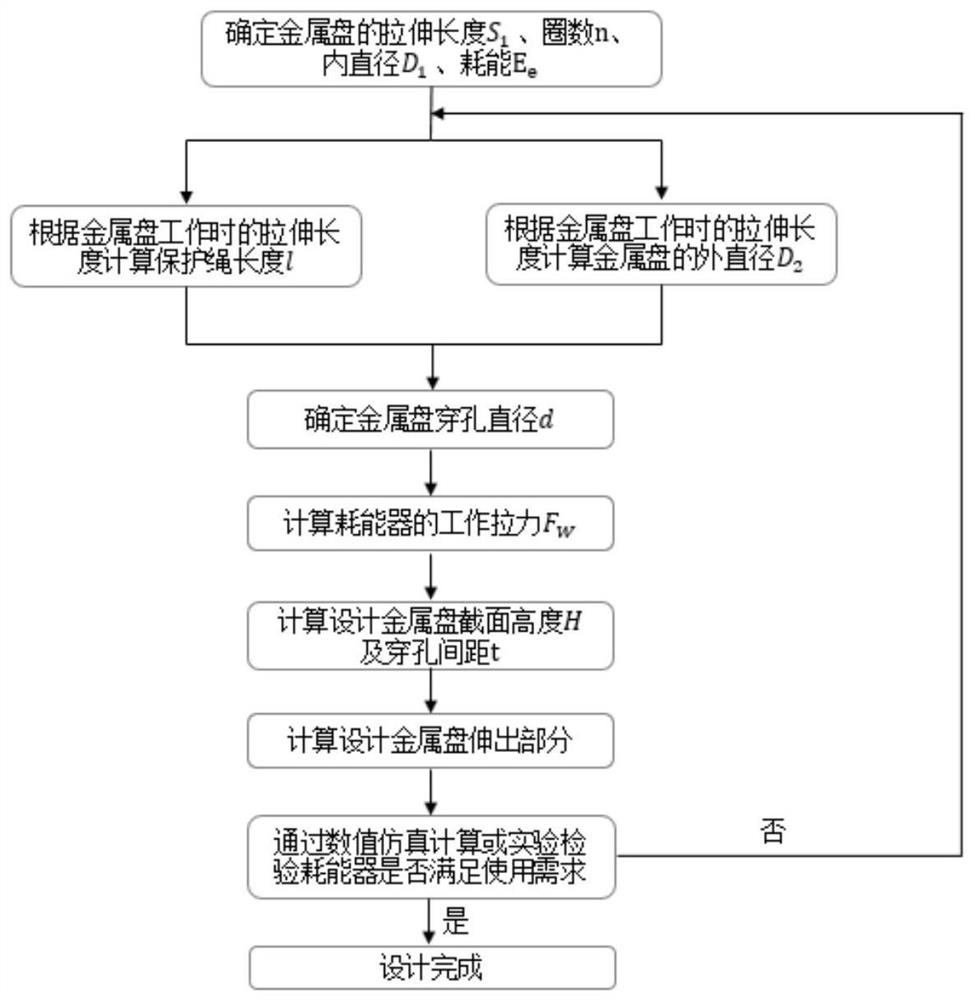

[0064] according to figure 1 The design flow shown is for computational design:

[0065] Determine the stretched length, the number of spiral turns, and the inner diameter of the metal disc when it is working: According to the allowable slippage length and space of the wire rope in the flexible protection system connected in this embodiment, the stretched length S of the energy dissipator in this embodiment is 1 is 1500mm, the helix number n of the single arm of the metal disc is 1.5, and the inner diameter D 1 is 80mm;

[0066] Calculate the length of the protection rope according to the tensile length of the metal disc when it is working: according to the formula l=1.1S 1 Calculate the length of the protective rope, the stretched length S of the metal plate 1 =...

Embodiment 2

[0079] like Figure 7 , Figure 8 Shown, a design method for a perforated yield-type energy dissipator. The energy dissipator includes four metal discs 1 with holes and one connecting bolt 10 when used in parallel and combined according to this embodiment.

[0080] like Figure 9 As shown, when the energy dissipator is used in parallel and in combination according to this embodiment, according to the practice in Embodiment 1, four metal discs with holes 1 are connected in parallel through bolts 10 to form the main structure.

[0081] The main structure of the energy dissipator ( Figure 9 ) by connecting the structure ( Figure 4 ) is connected with the wire rope of the flexible protection system to form Figure 7 , Figure 8 The complete structure of the energy dissipator when used in combination according to this embodiment is shown.

[0082] When the flexible protection system is impacted, the wire rope is pulled, and the 4 metal discs are simultaneously pulled from...

Embodiment 3

[0084] like Figure 10 Shown, a design method for a perforated yield-type energy dissipator. According to this embodiment, the energy dissipator includes two metal disks 1 with holes and one "8"-shaped steel cable 11 when used in series.

[0085] The main structure of the energy dissipator ( image 3 ) is connected by an "8"-shaped steel cable, and then connected with the flexible protection system steel cable, thereby forming a Figure 10 The complete structure of the energy dissipator when used in series according to this embodiment is shown.

[0086] When the energy dissipators are used in series according to this embodiment, the maximum slippage of the wire rope of the flexible protection system can be increased by 2 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com