Stone cutting machine with large cutting guide column lubricating device

A technology for lubricating devices and stone cutters, which is applied in the direction of distribution devices, lubricating parts, and engine lubrication. It can solve problems such as affecting service life, large lifting strokes, and wear, so as to increase working life, improve service life, and prevent grease. The effect of silting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

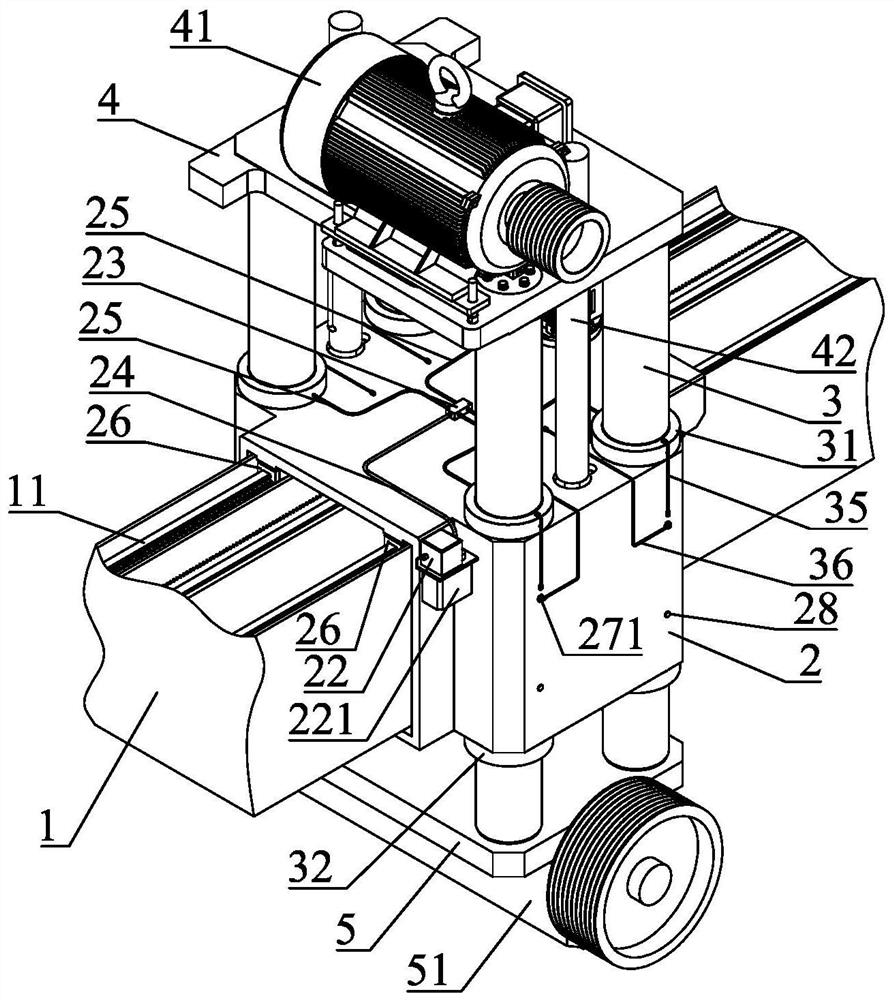

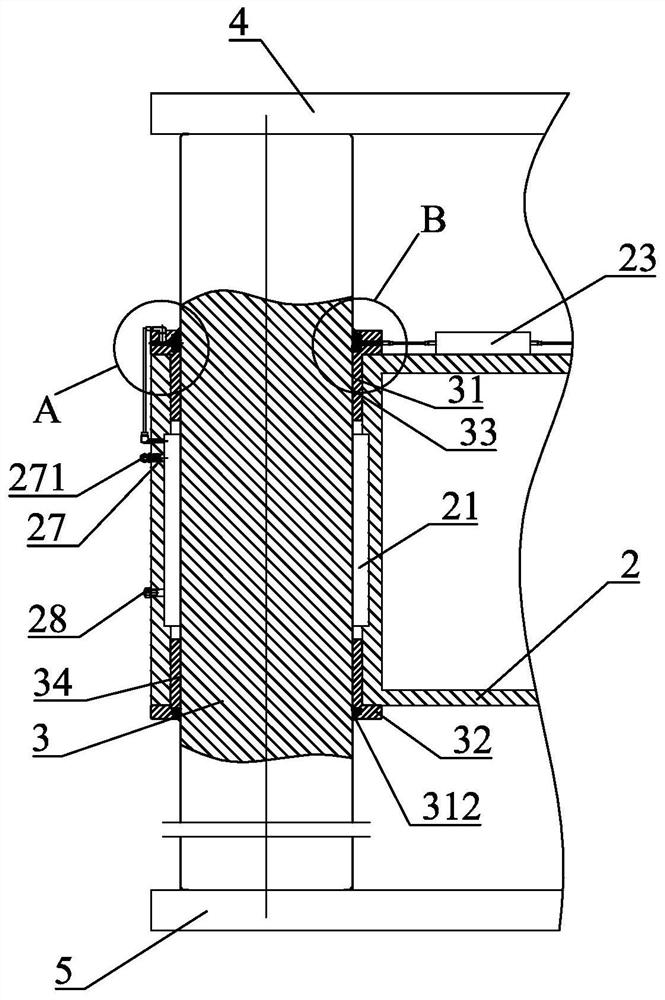

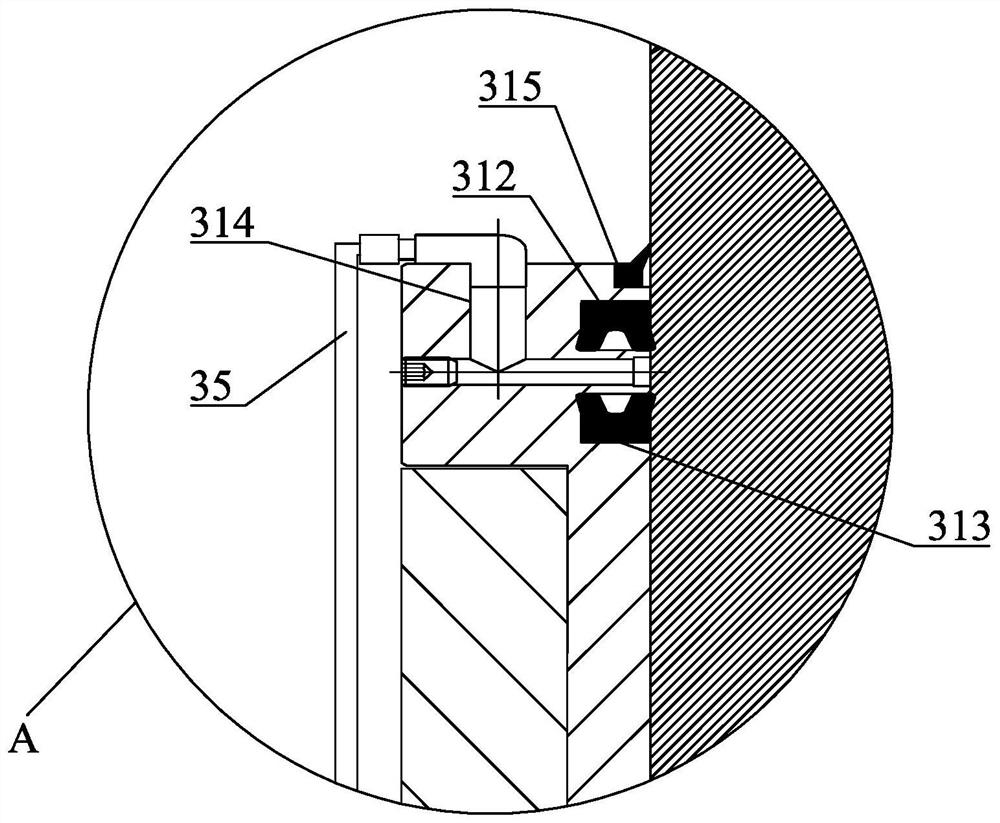

[0036] Such as Figure 1 to Figure 4 As shown, it is a stone cutter with a large cutting guide column lubrication device related to the present invention. It includes a beam 1 and a moving seat 2. The moving seat 2 is sleeved on the beam 1 and can be moved horizontally on the beam 1 Moving, the sliding seat 2 is provided with a guide column 3; an upper guide sleeve 31 is arranged between the guide column 3 and the mobile seat 2, and an oil storage device is arranged in the upper guide sleeve 31, so that An electric lubricating pump 22 is arranged on the moving base 2, and the electric lubricating pump 22 is also connected with an oil delivery pipe connected to the oil storage device; the moving base 2 and the guide column 3 are surrounded by a first An oil pool 21, the oil storage device is also connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com