A non-contact temperature field distance error calibration method for aero-engine hot end components

A technology for aero-engine and hot-end components, which is applied in the field of non-contact dynamic temperature field distance error calibration of hot-end components, can solve the problems of numerous influencing factors, harsh working environment of aero-engine temperature measuring instruments, and high technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to illustrate the technical solutions of the implementation examples of the present invention more clearly, the examples are further described in detail below in conjunction with the accompanying drawings. The content described here is only for explaining the present invention, and is not intended to limit the present invention.

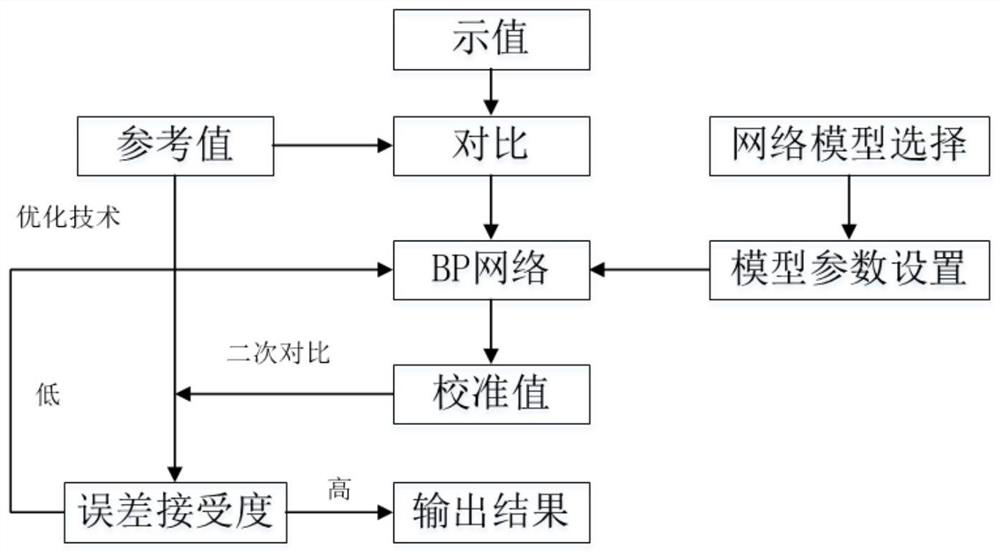

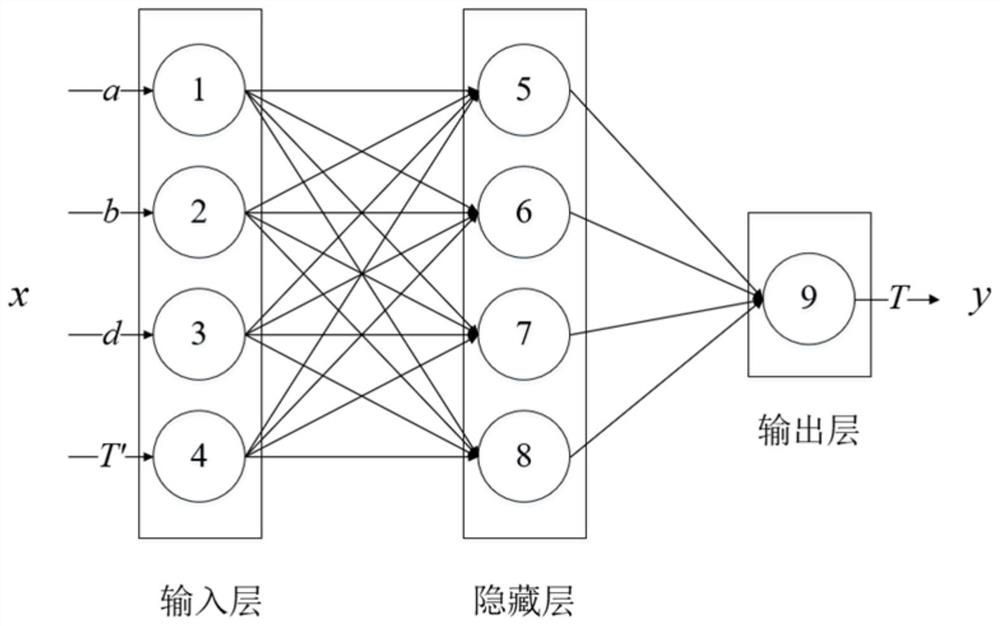

[0030] The technical route of the distance error calibration method is as follows: figure 1 As shown, the voltage data obtained by the experiment is converted into the corresponding temperature and then compared with the standard temperature of the black body furnace, and then the distance compensation is completed through the BP neural network algorithm to obtain the calibration value. Perform a secondary comparison of the calibration value with the reference value and analyze whether the error is within an acceptable range. If the error is large and not within the acceptable range, then continue to optimize until the requirement is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com