Preparation of low-temperature fraction for improving smoking quality and application of low-temperature fraction in cigarette heating

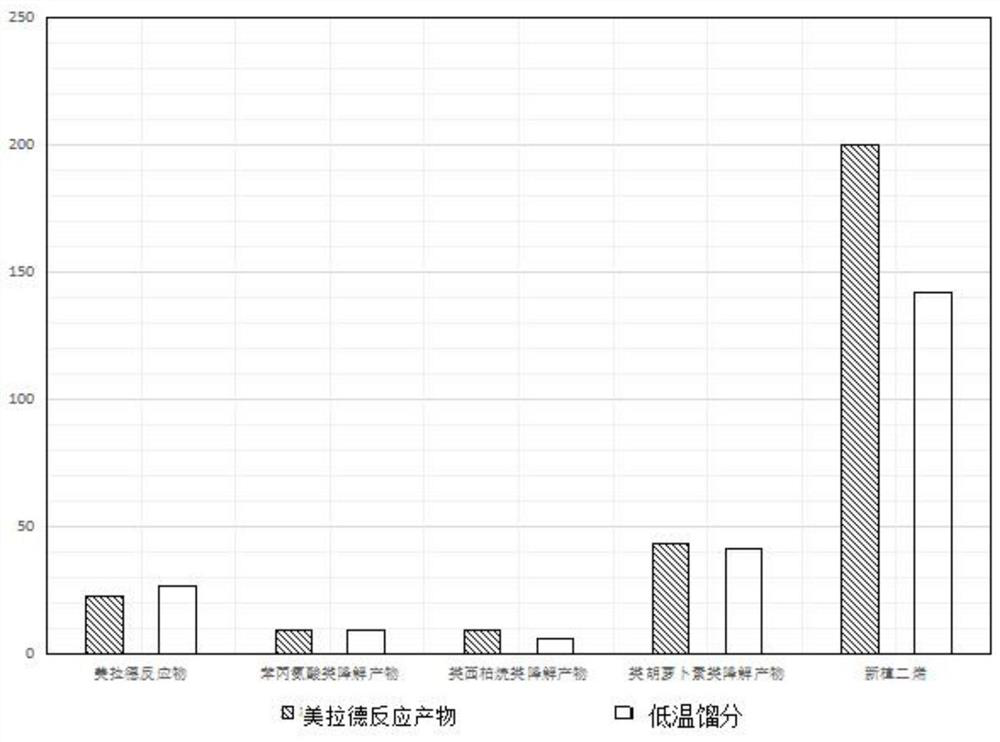

A technology of smoking quality and low temperature, applied in the field of heating cigarettes, can solve the problems of excessively controlled release, heavy chemical smell of flavors and fragrances, etc., and achieve the effect of reducing the release amount, rich and elegant smoke, and masking miscellaneous gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

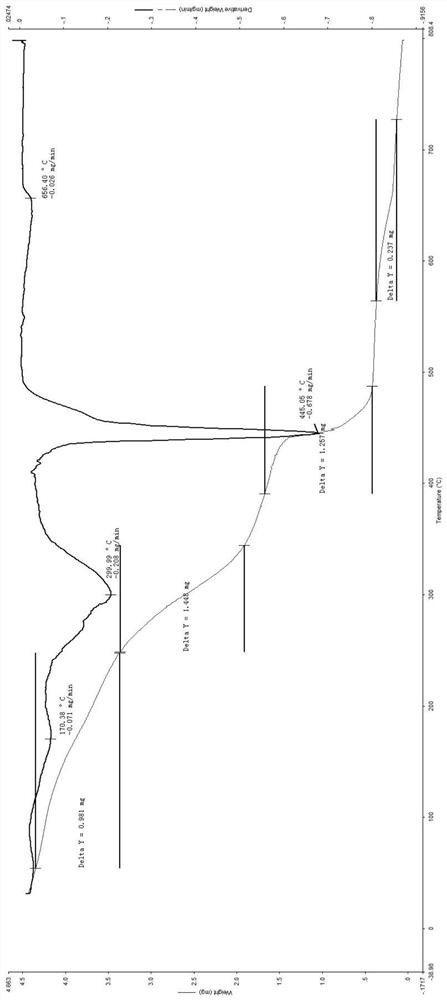

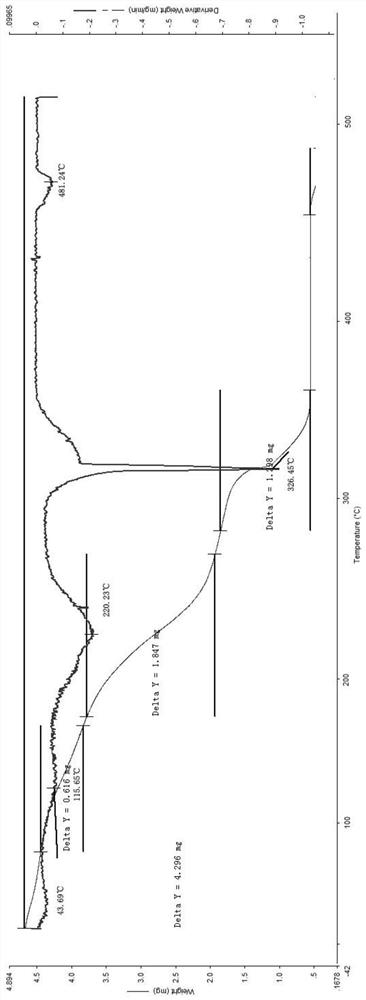

Image

Examples

Embodiment 1

[0032] A method for preparing a low-temperature distillate capable of improving suction quality, the preparation method comprising the following steps:

[0033] 1. Improving the suction quality leaf group formula design

[0034] Table 1 Formula design of leaf group for improving suction quality

[0035] serial number tobacco raw material Formula ratio (wt%) 1 2016 Henan Pingdingshan Ruzhou China Tobacco 100C3F 25 2 2016 C3F, No. 3 Nanjiang, Pingba, Anshun, Guizhou 15 3 In 2018, Guangxi Sun-dried Yellow Smoke Grade II 25 4 In 2017, Shifang, Sichuan, the second grade of sun-dried red smoke 25 5 2017 Maryland Smoke 5

[0036] The above-mentioned tobacco raw materials were prepared according to the formula ratio in Table 1 to obtain raw material samples.

[0037] 2. The method is divided into three steps:

[0038]Step 1. Obtaining tobacco sugars: extract the raw material sample with 30 times of petroleum ether for 2 hours, rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com