Sputum suction device capable of reducing vacuum residues and manufacturing process

A vacuum and air cavity technology, applied in the field of medical equipment, can solve the problems of respiratory skin rupture, large vacuum residual value, and difficult vacuum residual value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

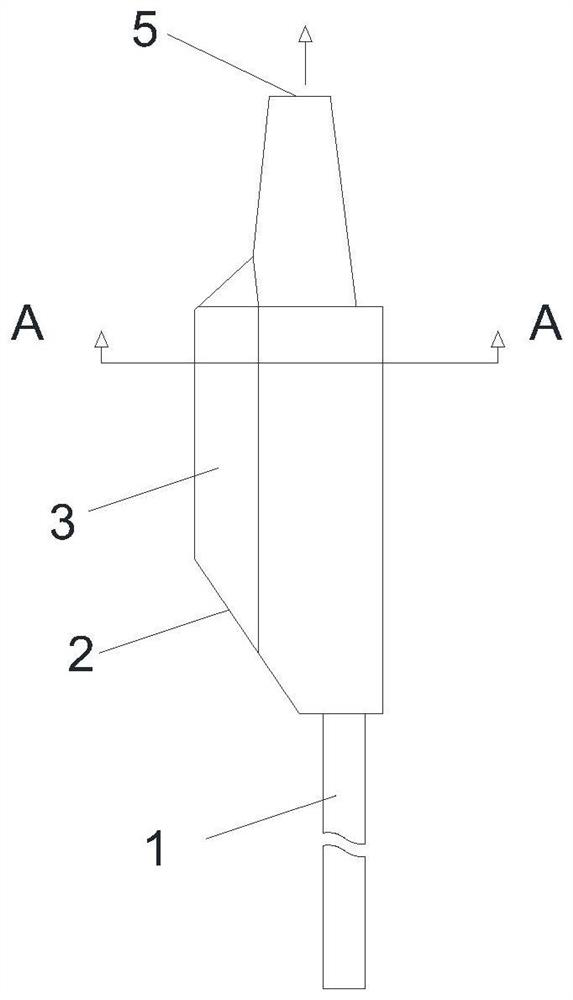

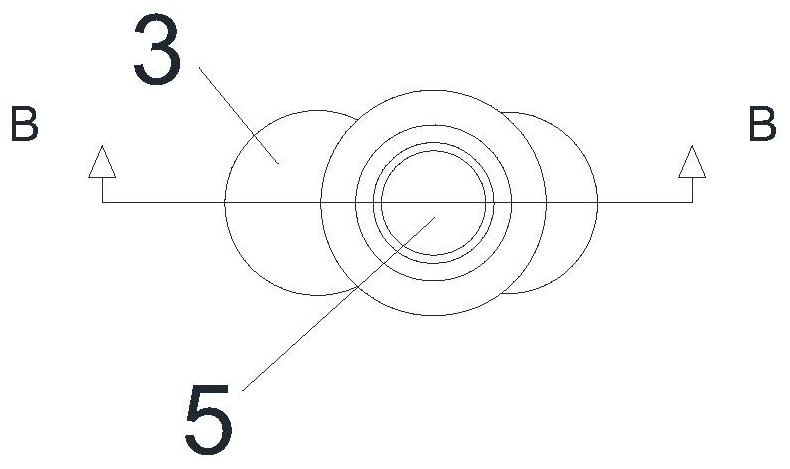

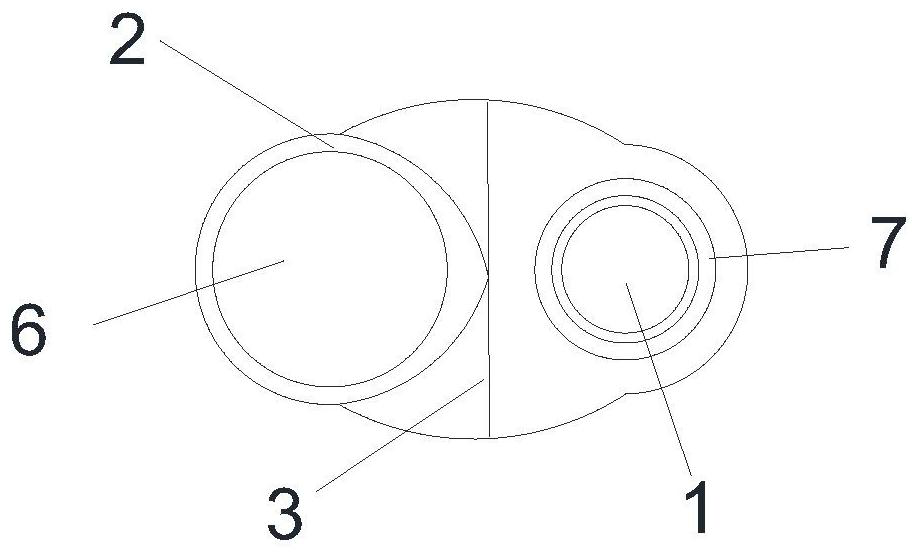

[0051] Such as Figure 6-12As shown, the present invention provides a sputum suction device that reduces vacuum residue, comprising a body 3 made of ABS material, the ABS material is a heat-melt polypropylene material, a negative pressure port 5 and a negative pressure tube on the body 3 The airtight connection, the negative pressure tube is connected with the external negative pressure equipment to provide a negative pressure source for the patient to suck sputum. The third air chamber 8, the first air chamber 6 and the third air chamber 8 are arranged in parallel, the third air chamber 8 is a linear shape connected at both ends, one end of the third air chamber 8 is a negative pressure port 5, and The other end of 8 is obliquely provided with manual control port 2. In this embodiment, in order to reduce resistance, the negative pressure port 5 and the manual control port 2 are straight cylindrical structures arranged on the same straight line. Wherein, the blind ends of th...

Embodiment 2

[0058] This embodiment has been improved on the basis of Embodiment 1, and other structures are the same, the difference is: as Figure 15-18 As shown, the present embodiment provides a suction device for reducing vacuum residue, the valve 9 is set as a sealing plate 91 made of hard material, and the sealing plate 91 is a baffle structure, and the baffle structure is specifically the The bottom is provided with a rotating part 11 , and the rotating part 11 rotates around an axis 13 .

[0059] In this embodiment, the bottom of the baffle of the sealing plate 91 structure is provided with a transverse baffle 95, and an included angle b is set between the baffle of the sealing plate 91 and the transverse baffle 95, and the angle range of the included angle b is 0°

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com