Biological test tube cleaning device

A technology for cleaning devices and test tubes, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as laborious work, low work efficiency, and decreased work enthusiasm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A biological test tube cleaning device, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 8 As shown, it includes a base 1, a slotted fixing frame 2, a driving mechanism 3 and a cleaning mechanism 4. The left side of the top of the base 1 is symmetrically fixed with a slotted fixing frame 2. A cleaning mechanism 4 is provided on the frame 2, and the cleaning mechanism 4 contacts and cooperates with the driving mechanism 3.

[0029] The driving mechanism 3 includes a first fixed block 31, a cylinder 32, a second fixed block 33, a push rod 34 and a sliding block 35. A cylinder 32 is provided, and a second fixed block 33 is affixed to the ends of the telescopic rods of the cylinders 32 on the front and rear sides, and a push rod 34 is affixed symmetrically to the front and back of the left side of the second fixed block 33. A sliding block 35 is fixedly connected between them.

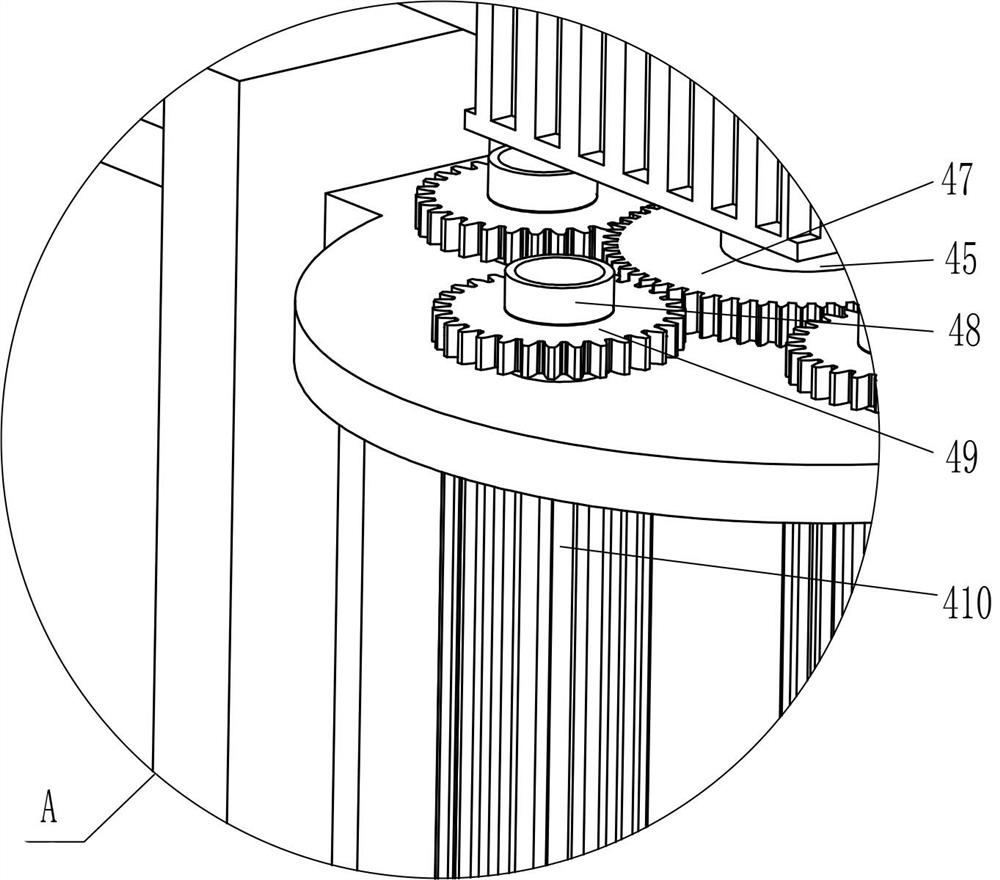

[0030] The cleaning mechanism 4 includes a slide plate 41, a slide bar 42, ...

Embodiment 2

[0033] On the basis of Example 1, such as figure 1 , figure 2 , Figure 5 and Image 6 As shown, a clamping and positioning mechanism 5 is also included. The clamping and positioning mechanism 5 includes a first limit block 51, an L-shaped fixed block 52, a first spring 53, a fourth fixed block 54 and a guide wheel 55. The top of the base 1 The middle is affixed with the first stopper 51, and the front and rear sides of the first stopper 51 middle part are all affixed with the L-shaped fixed block 52, and the inner side of the L-shaped fixed block 52 is symmetrically affixed with the first spring 53. A fourth fixed block 54 is fixedly connected between the tail ends of the first springs 53 on the side, and the fourth fixed block 54 is provided with guide wheels 55 in a left and right symmetrical rotation.

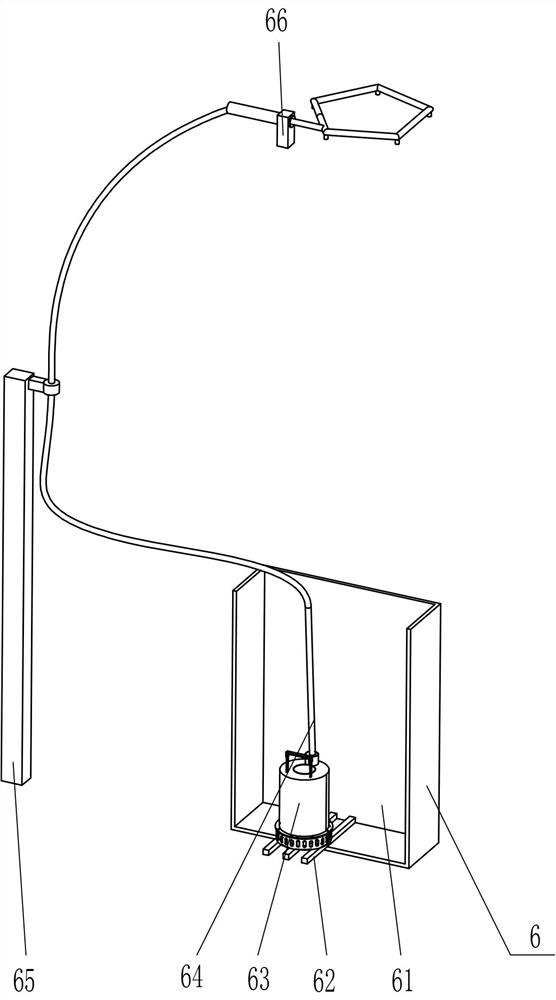

[0034]Also includes a delivery mechanism 6, the delivery mechanism 6 includes a water storage frame 61, the fifth fixed block 62, a water pump 63, a hose 64, the sixth ...

Embodiment 3

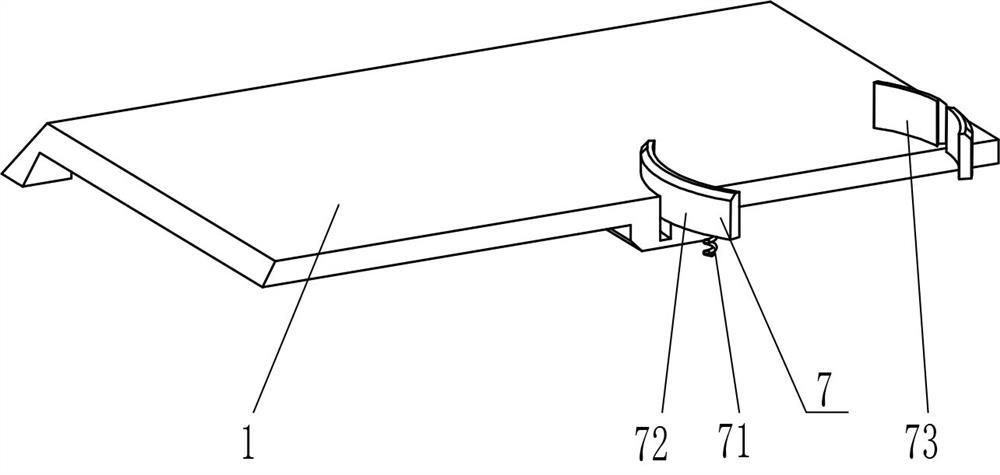

[0038] On the basis of embodiment 1 and embodiment 2, such as figure 1 , figure 2 and Figure 7 As shown, a fixing device 7 is also included. The fixing device 7 includes a second spring 71, a second limiting block 72 and an eighth fixing block 73. The left part of the base 1 is slidably provided with a second limiting block 72, and the second The bottom of the limiting block 72 and the inside of the base 1 are fixed with a second spring 71 symmetrically front and back, and the middle of the top of the base 1 is fixed with an eighth fixing block 73 .

[0039] When the test tube rack is placed under the cleaning rod 410, the test tube rack is in contact with the second stopper 72, and due to the action of the second spring 71, the test tube rack slides over the second stopper 72, and then the second stopper 72 Cooperate with the eighth fixed block 73 to limit the test tube. When the test tube is cleaned, press the second limit block 72 to move downward, the second spring 71 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com