Method for removing organic matter in waste mq bonded NdFeB magnetic powder by using sodium hydroxide chemical reaction method

A technology of sodium hydroxide and chemical reaction, applied to the removal of solid waste, etc., can solve problems such as incomplete methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

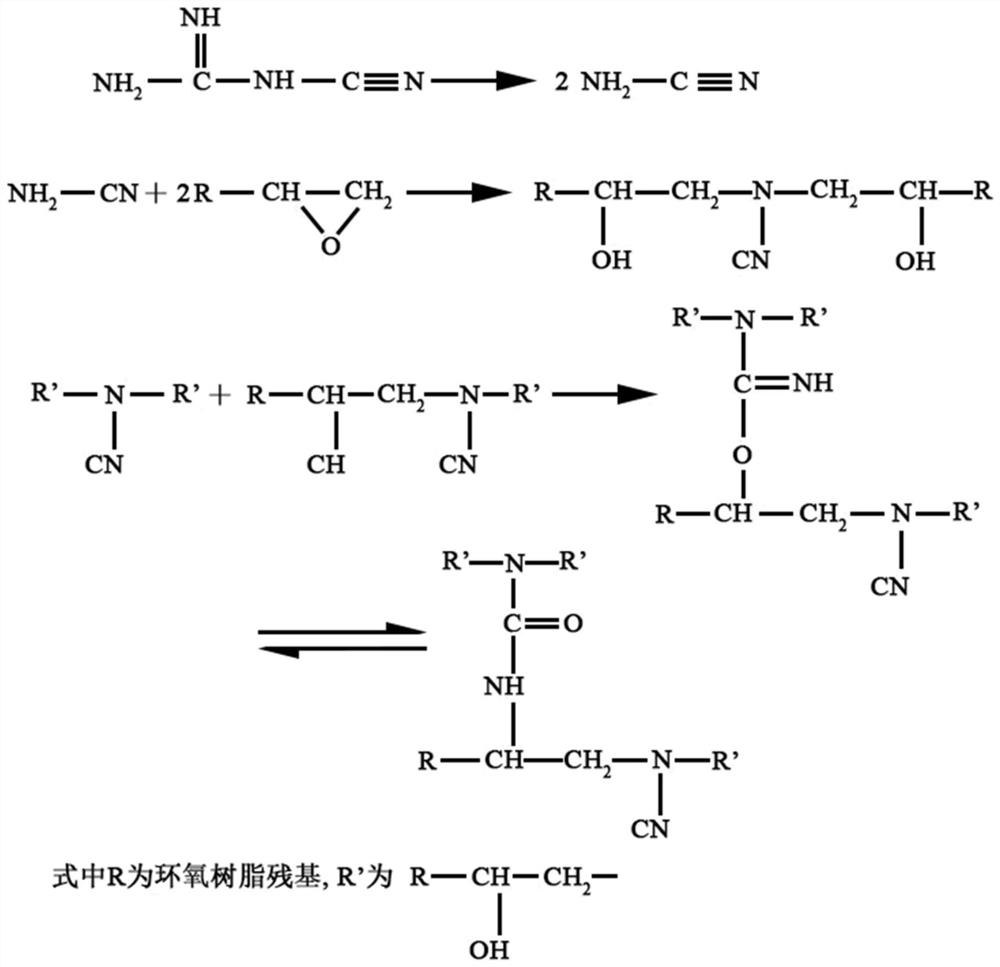

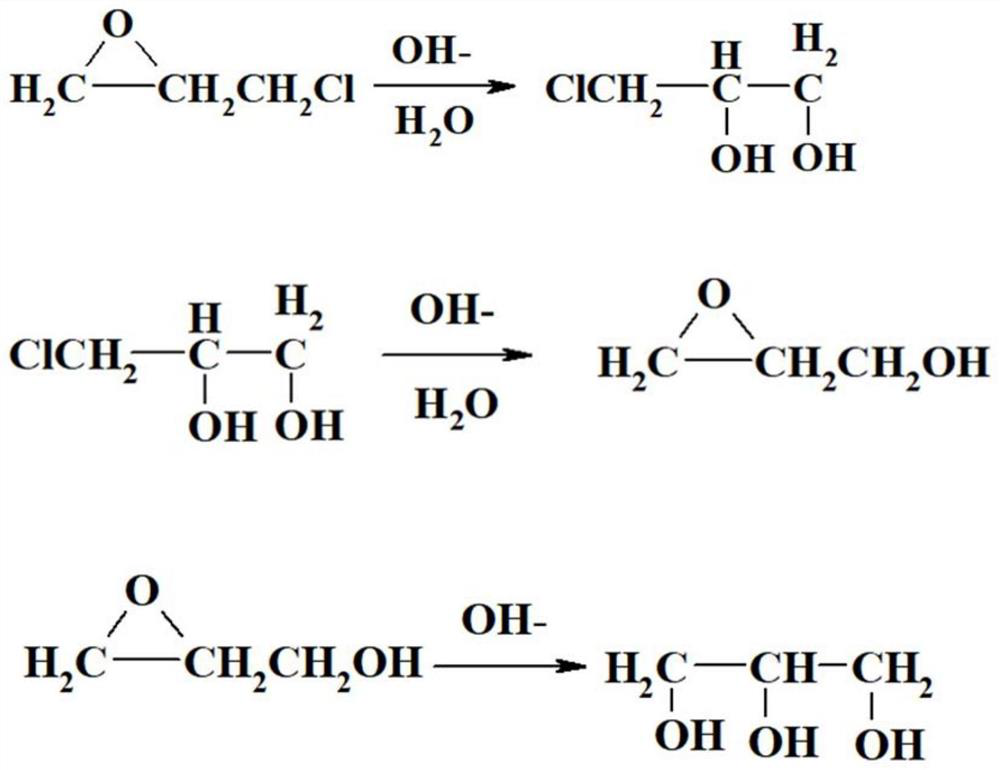

Method used

Image

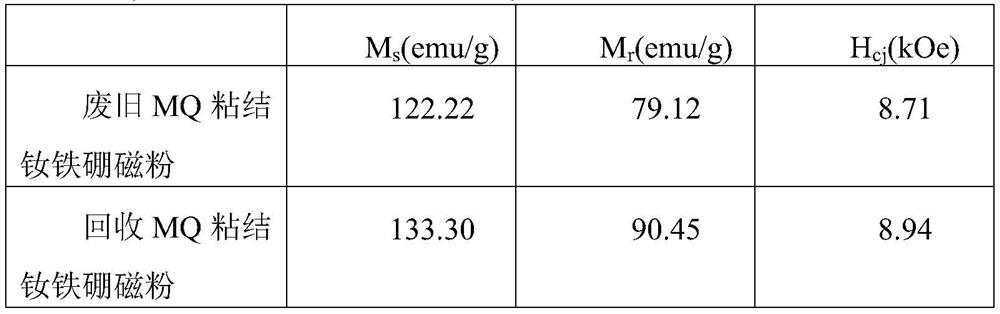

Examples

example 1

[0016] A kind of mixed solvent formula for removing carbon and oxygen of waste and old MQ bonded NdFeB magnetic powder used in the present embodiment is: by solid mass and liquid volume ratio sodium hydroxide / dehydrated alcohol 3g / 100ml.

[0017] The method for removing carbon and oxygen of a kind of waste and old MQ bonded NdFeB magnetic powder involved in the present invention is carried out according to the following steps:

[0018] 1. Remove the solidified organic matter in the waste MQ bonded NdFeB magnetic powder: Put the waste MQ bonded NdFeB magnetic powder and the mixed solvent into the three-necked flask according to the mass ratio of 1:6, keep the pressure of the three-necked flask at normal pressure, and use poly Stir at a constant speed with a tetrafluoroethylene stirring paddle, and control the temperature at 20°C through a water bath, keep it warm for 6 hours, and take it out after the end to obtain the magnetic powder A;

[0019] 2. Remove the decomposition pro...

example 2

[0027] A kind of mixed solvent formula for removing carbon and oxygen of waste and old MQ bonded NdFeB magnetic powder used in the present embodiment is: by solid mass and liquid volume ratio sodium hydroxide / dehydrated alcohol 1g / 100ml.

[0028] The method for removing carbon and oxygen of a kind of waste and old MQ bonded NdFeB magnetic powder involved in the present invention is carried out according to the following steps:

[0029] 1. Remove the solidified organic matter in the waste MQ bonded NdFeB magnetic powder: Put the waste MQ bonded NdFeB magnetic powder and the mixed solvent into a three-necked flask at a mass ratio of 1:8, keep the pressure of the three-necked flask at normal pressure, and use poly Stir at a constant speed with a tetrafluoroethylene stirring paddle, and control the temperature at 70°C through a water bath, keep it warm for 24 hours, and take it out after the end to obtain the magnetic powder A;

[0030] 2. Remove the decomposition products of cure...

example 3

[0038] A kind of mixed solvent formula for removing carbon and oxygen of waste and old MQ bonded NdFeB magnetic powder used in the present embodiment is: by solid mass and liquid volume ratio sodium hydroxide / dehydrated alcohol 1g / 100ml.

[0039] The method for removing carbon and oxygen of a kind of waste and old MQ bonded NdFeB magnetic powder involved in the present invention is carried out according to the following steps:

[0040] 1. Remove the solidified organic matter in the waste MQ bonded NdFeB magnetic powder: Put the waste MQ bonded NdFeB magnetic powder and the mixed solvent into the three-necked flask according to the mass ratio of 1:6.5, keep the pressure of the three-necked flask at normal pressure, and use poly Stir at a constant speed with a tetrafluoroethylene stirring paddle, and control the temperature at 50°C through a water bath, keep it warm for 20 hours, and take it out after the end to obtain the magnetic powder A;

[0041] 2. Remove the decomposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com