Three-dimensional optical coherence elastography detection device applied to corneal refraction operation

A refractive surgery, three-dimensional optical technology, applied in the field of three-dimensional optical coherent elastography detection devices, can solve the problems of affecting the detection results, contamination of debris, contamination of convex lenses with debris, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

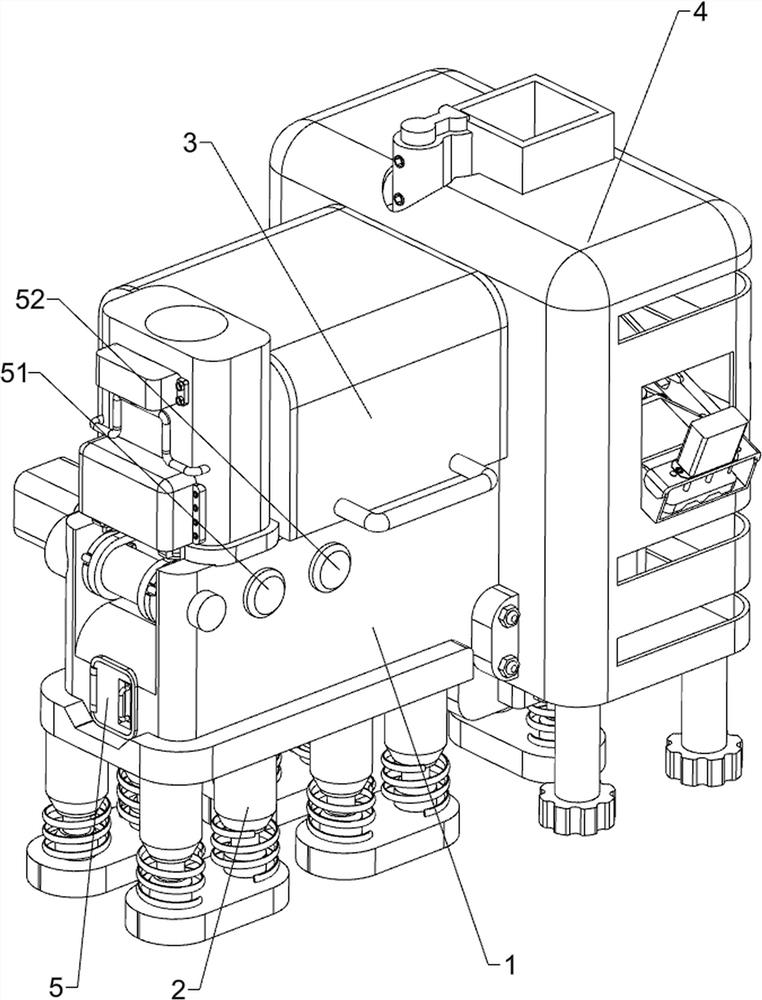

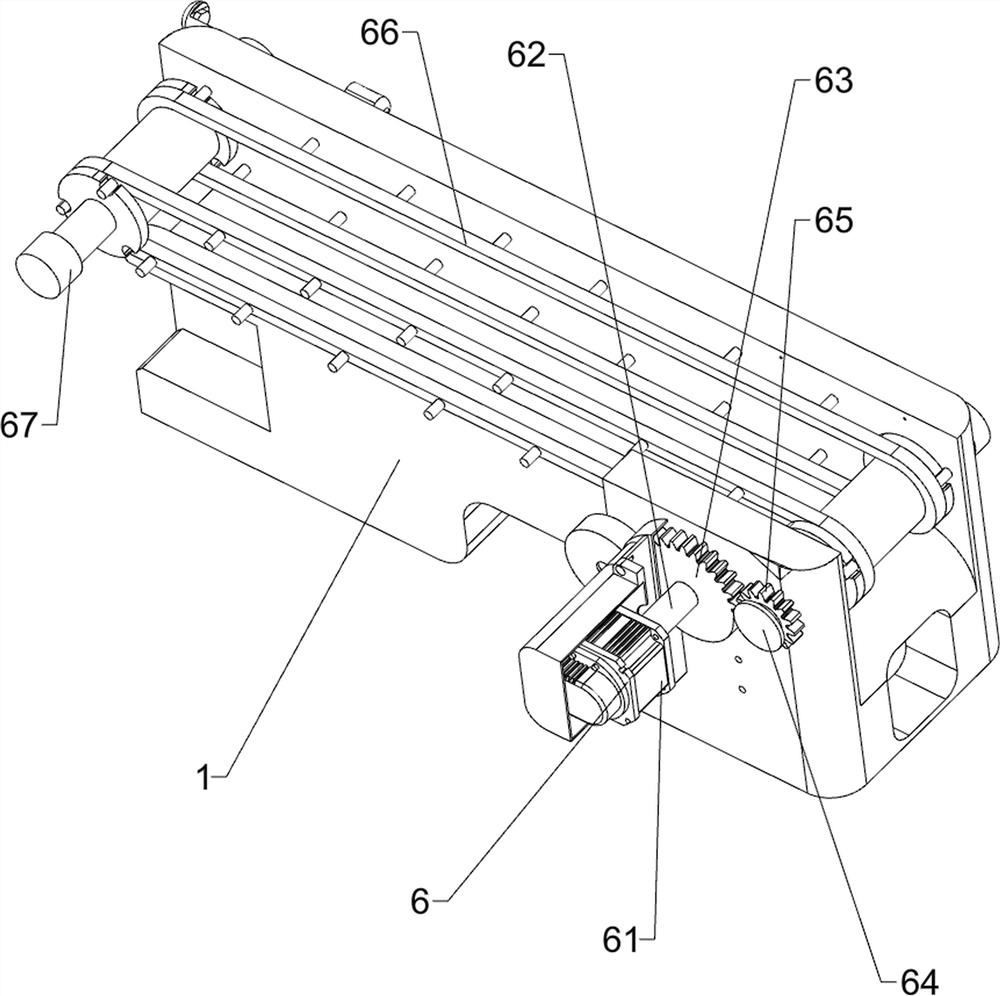

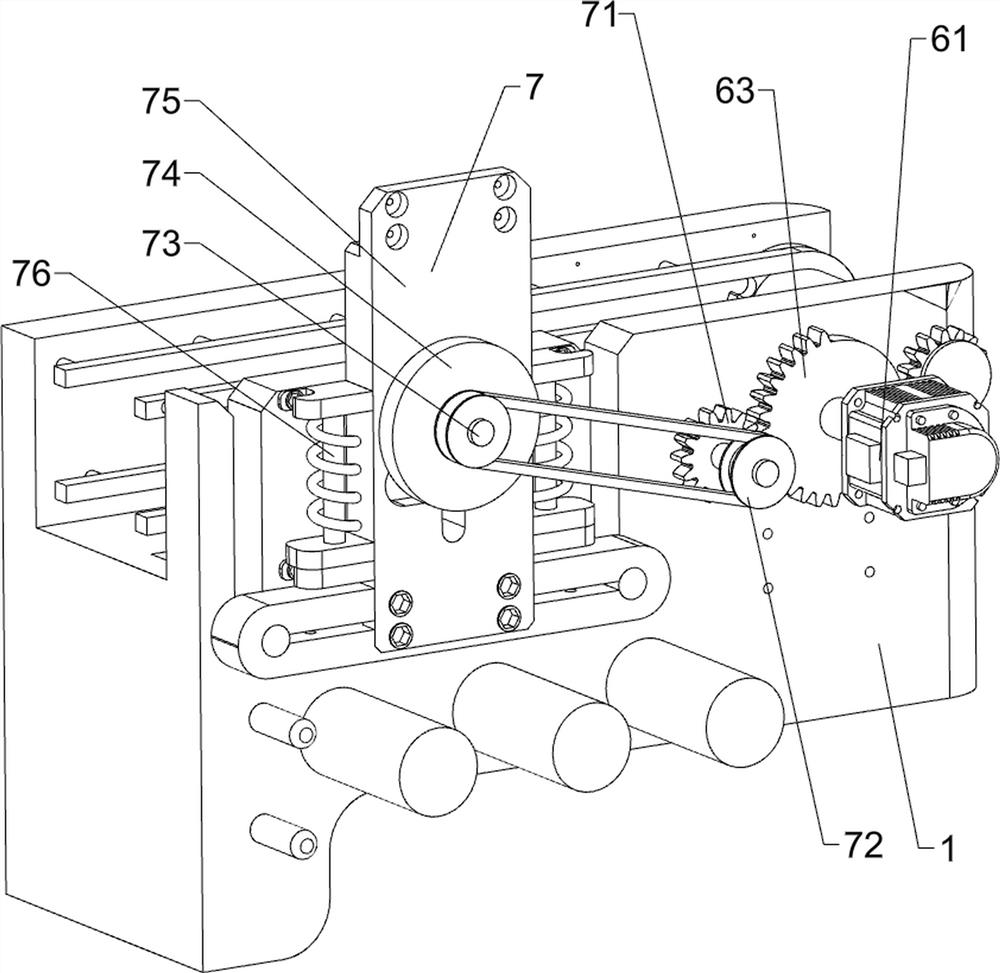

[0089] A three-dimensional optical coherence elastography detection device applied to corneal refractive surgery, such as Figure 1-Figure 6 As shown, it includes a detection box 1, a buffer base 2, a light-shielding cover 3, a protective cover 4, a start button 51, a stop button 52, a feeding mechanism 6 and a detection mechanism 7, and the bottom of the detection box 1 is provided with a plurality of Buffer base 2, a light-shielding cover 3 is provided on the left side of the top of the detection box body 1, a protective cover 4 is provided on the right side of the detection box body 1, a start button 51 is provided on the front left side of the upper part of the detection box body 1, and a start button 51 is provided on the upper front side of the detection box body 1. The left side is provided with a stop button 52, and the stop button 52 is positioned at the right side of the start button 51. The top of the detection box 1 is provided with a feeding mechanism 6, and the ri...

Embodiment 2

[0094] On the basis of Example 1, such as Figure 7-Figure 15 As shown, also includes feeding mechanism 8, and feeding mechanism 8 includes charging cylinder 81, safety baffle plate 82, lifting inclined block frame 83, return spring post 84, positioning top plate 85, material retaining tongue plate 86, water tank 87 , an atomizing device 88, an air duct 89 and a first pressure sensor 810, a charging tube 81 is arranged on the left side of the top of the detection box 1, and the charging tube 81 is located on the left side of the light-shielding cover 3, and the lower part of the left side of the charging tube 81 is provided There is a safety baffle 82, and the bottom left side of the charging cylinder 81 is provided with a positioning top plate 85, and the positioning top plate 85 is positioned at the inner side of the safety baffle 82, and four return spring columns 84 are arranged at intervals on the left side of the bottom of the positioning top plate 85, and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com