Segment assembly bridge polymer structural adhesive packaging process

A polymer, structural adhesive technology, used in packaging, bottling machines, bottle filling and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

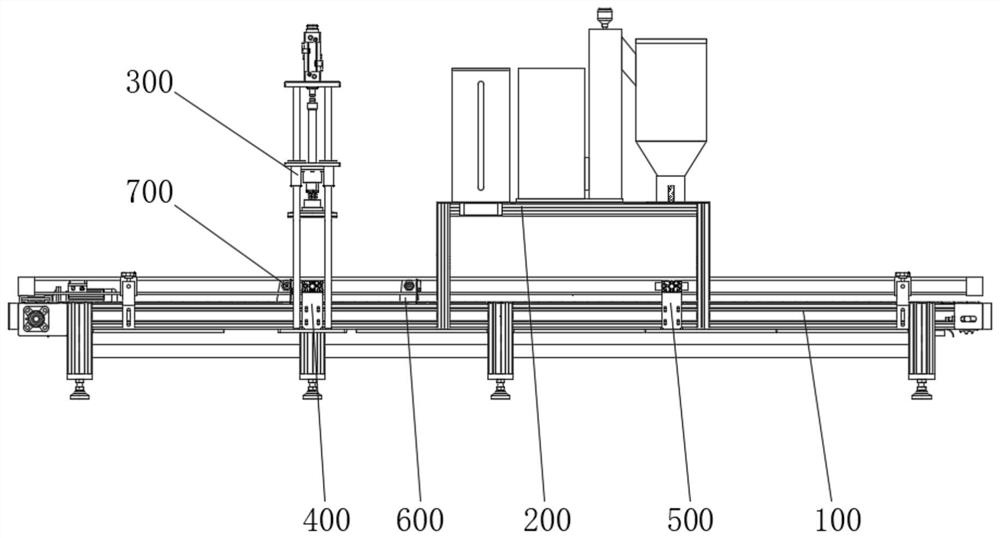

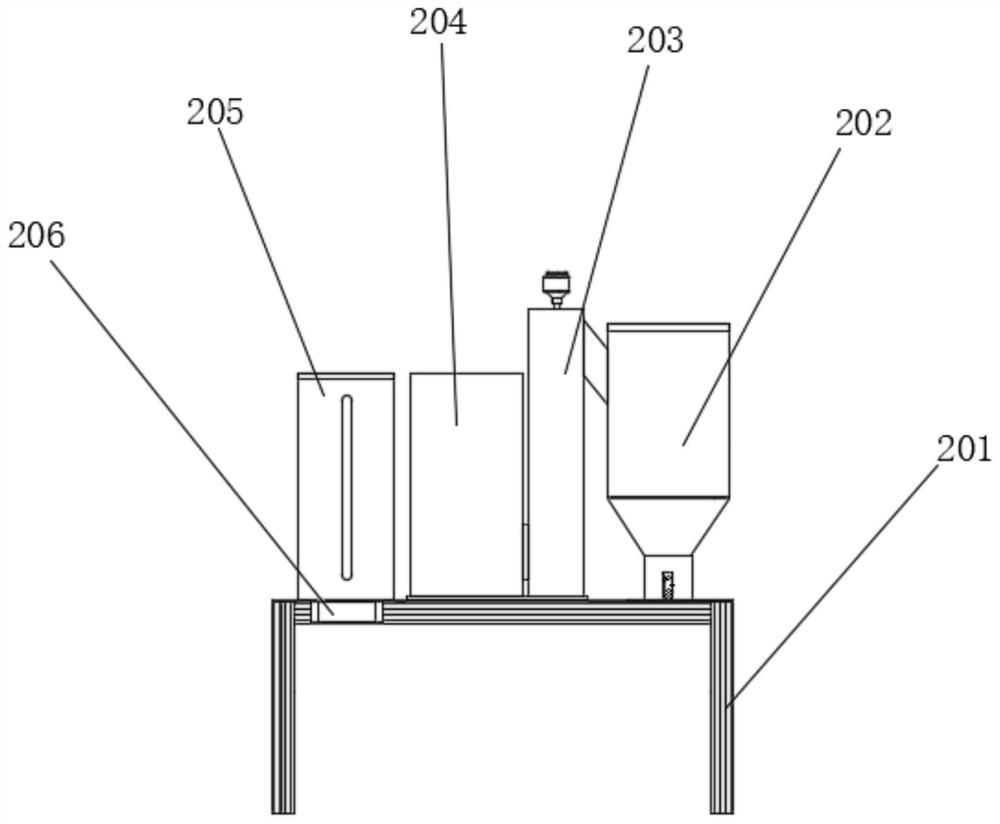

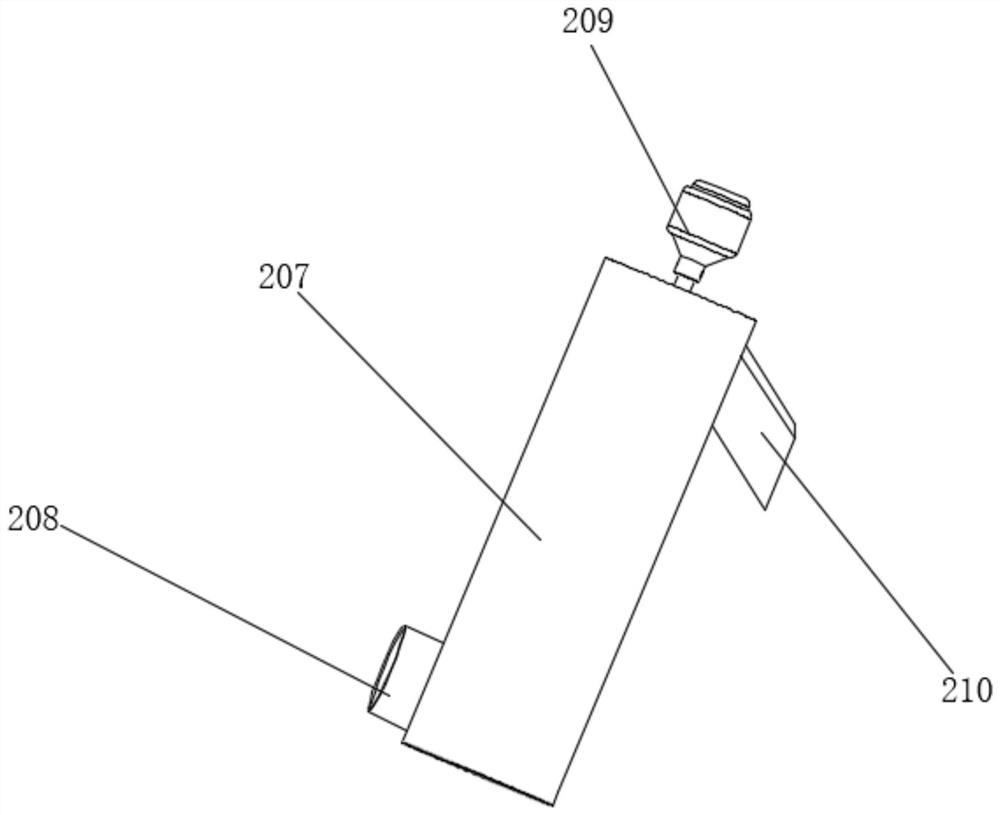

[0034] see Figure 1-7 As shown, this embodiment is a packaging device, including a conveyor 100, a filling and capping mechanism 200, a capping mechanism 300, a first positioning mechanism 400, a second positioning mechanism 500, a first limiting mechanism 600, a second limiting mechanism mechanism 700, the top of the conveyor 100 near the middle is provided with a filling and capping mechanism 200, and the conveyor 100 is equipped with a second positioning mechanism 500 on both sides below the filling and capping mechanism 200, so A first limit mechanism 600 is installed on one side of the conveyor 100 close to one end of the filling capping mechanism 200, the conveyor 100 runs through the capping mechanism 300, and a second limit mechanism is installed on one side of the conveyor 100. A positioning mechanism 700, the capping mechanism 300 is located between the first limiting mechanism 600 and the second limiting mechanism 700, and the first positioning mechanism 400 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com