A kind of preparation method of small molecule sodium hyaluronate

A technology of sodium hyaluronate and small molecules, applied in the field of preparation of small molecule sodium hyaluronate, can solve problems such as easy yellowing, and achieve the effects of promoting degradation, reducing molecular weight and increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

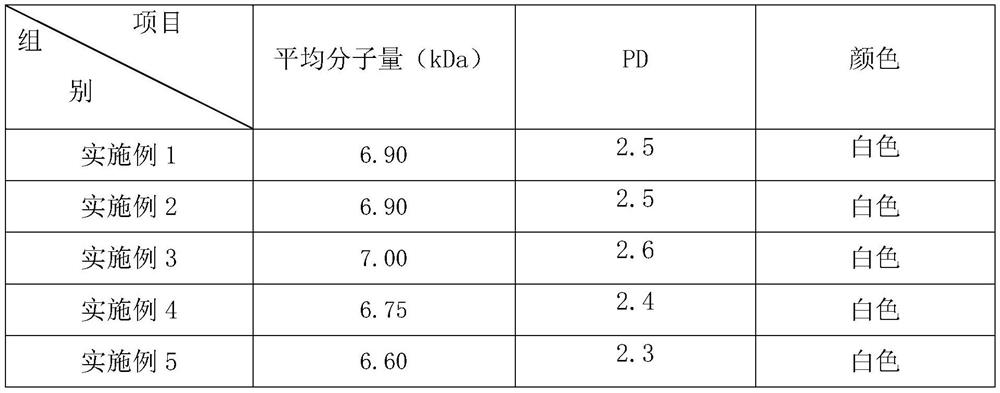

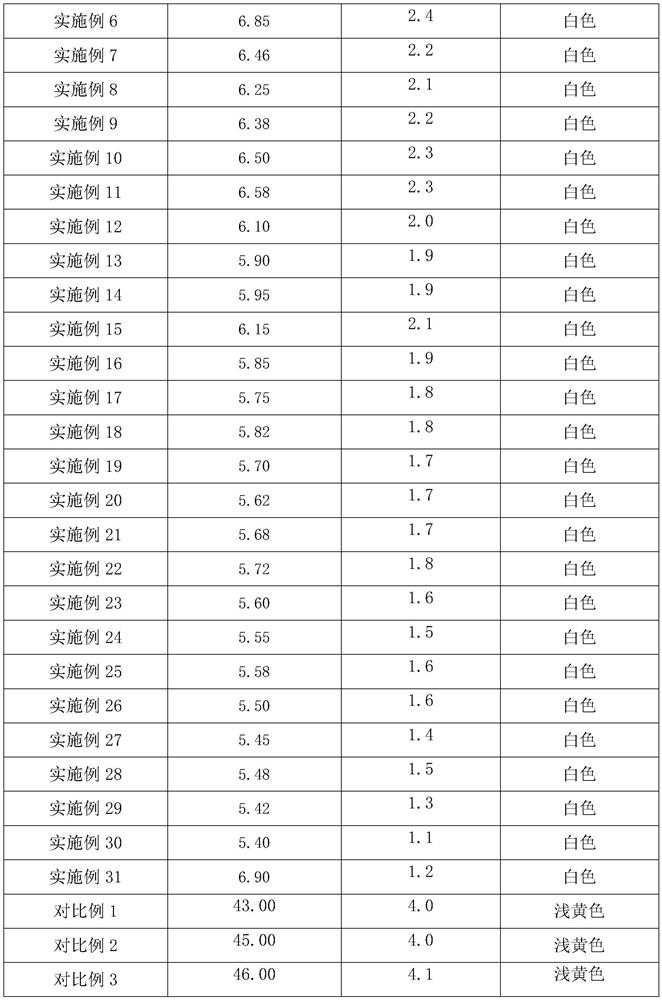

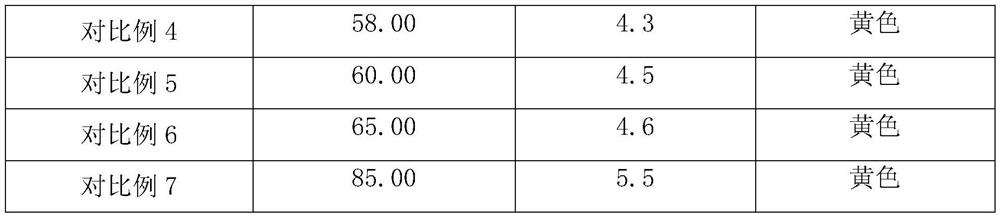

Examples

Embodiment 1

[0044] A preparation method of small molecule sodium hyaluronate, characterized in that it comprises the following steps:

[0045] S1: Add 5L of organic solvent to the ultrasonic high-pressure multifunctional reaction kettle, and dissolve 0.5kg of sodium hyaluronate solid with a molecular weight of 1.2MDa in 5L of organic solvent at a stirring speed of 1000r / min, and stir and mix for 0.5h ; At 40°C, add 0.04L of acetic acid and 0.02L of hydrogen peroxide dropwise to the ultrasonic high-pressure multifunctional reaction kettle in sequence. After the ultrasonic frequency is 15KHz, after ultrasonic stirring for 15min, the stirring speed is 1000r / min. , stirred for 5h to obtain a suspension;

[0046] S2: Under the condition that the drum speed is 1200r / min, the suspension is collected by a centrifuge; Liquid, control the temperature of the ultrasonic high-pressure multifunctional reactor to be -5-0 °C, adjust the pH value of the mixed solution to 9 with 1mol / L sodium hydroxide so...

Embodiment 2

[0051] A method for preparing small-molecule sodium hyaluronate, characterized in that, the difference from Example 1 is that in the preparation process S1 of small-molecule sodium hyaluronate, the organic solvent is 90% methanol aqueous solution, and the mixture is stirred for 6.5 hours; In S2, adjust the pH value of the mixed solution B to 10 with 1mol / L sodium hydroxide solution.

Embodiment 3

[0053] A method for preparing small-molecule sodium hyaluronate, which is characterized in that, the difference from Example 1 is that in the preparation process S1 of small-molecule sodium hyaluronate, the organic solvent is 90% methanol aqueous solution, stirred for 8 hours; S2 , adjust the pH of the mixture B to 11 with 1mol / L sodium hydroxide solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com