An ultra-quiet polypropylene piping material

A polypropylene and ultra-quiet technology, which is applied in the field of polypropylene pipe materials with ultra-quiet effects, can solve the problems of poor dispersion and compatibility of inorganic fillers, limited quiet effect of pipes, and reduced mechanical properties of pipes, so as to achieve good mechanical properties. Performance, improved compatibility, improved mute effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

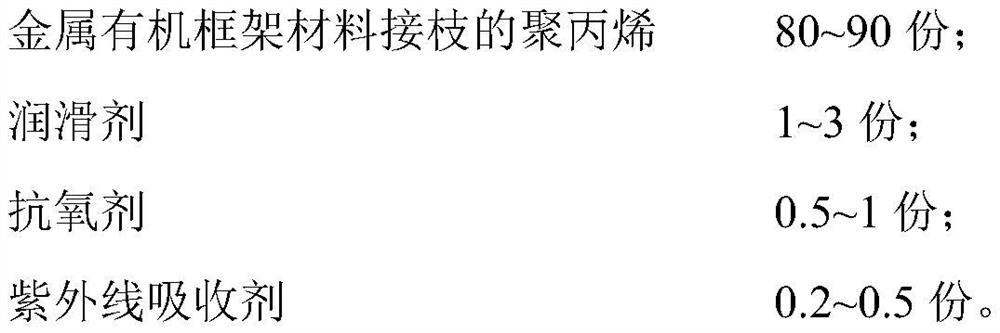

[0032] A kind of polypropylene pipeline material with ultra-quiet effect, in parts by weight, the raw materials include:

[0033]

[0034] Wherein, the preparation method of the polypropylene grafted by the metal organic framework comprises the following steps:

[0035] (1) ZrCl with a molar ratio of 1:1.5 4 and 2-aminoterephthalic acid dissolved in the solvent N,N-dimethylformamide, ZrCl 4 The mass volume ratio of N,N-dimethylformamide and N,N-dimethylformamide is 1g:120mL; add hydrochloric acid with a mass concentration of 36%, and a volume ratio of N,N-dimethylformamide of 1:55, and ultrasonically disperse for 25min. Then heated to 130°C to react for 36h, cooled to room temperature, filtered, washed and dried the product to obtain a metal organic framework material;

[0036] (2) Add the metal-organic framework material to dichloromethane, ultrasonically disperse evenly, and then add methacrylic anhydride. The ratio of metal-organic framework material, dichloromethane a...

Embodiment 2

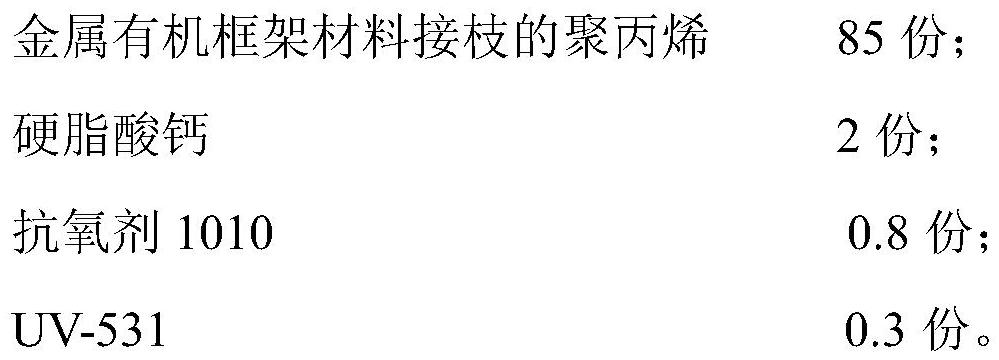

[0040] A kind of polypropylene pipeline material with ultra-quiet effect, in parts by weight, the raw materials include:

[0041]

[0042]

[0043] Wherein, the preparation method of the polypropylene grafted by the metal organic framework comprises the following steps:

[0044] (1) ZrCl with a molar ratio of 1:1 4 and 2-aminoterephthalic acid dissolved in the solvent N,N-dimethylformamide, ZrCl 4 The mass volume ratio of N,N-dimethylformamide and N,N-dimethylformamide is 1g:100mL; add hydrochloric acid with a mass concentration of 35% and a volume ratio of N,N-dimethylformamide of 1:50, and ultrasonically disperse for 20min. Then heated to 120°C to react for 48h, cooled to room temperature, filtered, washed and dried the product to obtain a metal organic framework material;

[0045] (2) Add the metal-organic framework material to dichloromethane, ultrasonically disperse evenly, and then add methacrylic anhydride. The ratio of metal-organic framework material, dichloro...

Embodiment 3

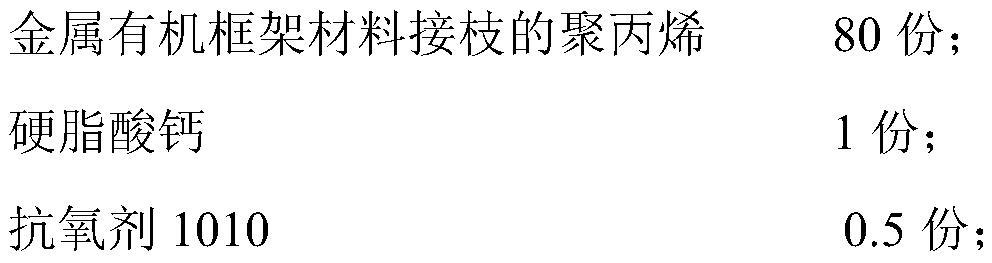

[0049] A kind of polypropylene pipeline material with ultra-quiet effect, in parts by weight, the raw materials include:

[0050]

[0051] Wherein, the preparation method of the polypropylene grafted by the metal organic framework comprises the following steps:

[0052] (1) ZrCl with a molar ratio of 1:2 4 and 2-aminoterephthalic acid dissolved in the solvent N,N-dimethylformamide, ZrCl 4 The mass volume ratio of N,N-dimethylformamide and N,N-dimethylformamide is 1g:150mL; add hydrochloric acid with a mass concentration of 37%, and a volume ratio of N,N-dimethylformamide of 1:60, and ultrasonically disperse for 30min. Then heated to 140°C for 24 hours, cooled to room temperature, filtered, washed, and dried to obtain a metal-organic framework material;

[0053] (2) Add the metal-organic framework material to dichloromethane, and methacrylic anhydride is added after ultrasonic dispersion is uniform. The ratio of metal-organic framework material, dichloromethane and methacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com