In-tunnel fabricated bridge structure and construction method thereof

A bridge structure and assembly technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as insufficient bridge efficiency, hidden safety hazards, and multiple installation structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

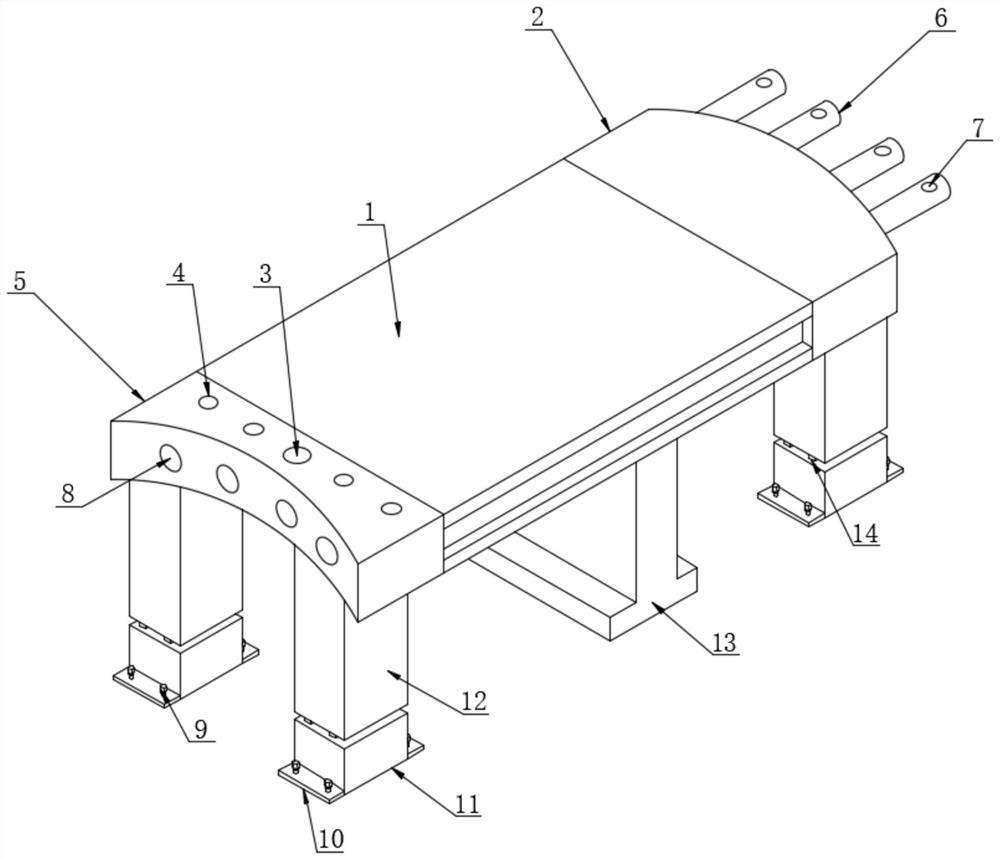

[0046]see Figure 1-Figure 6 , the present invention provides a technical solution:

[0047] An assembled bridge structure in a tunnel and a construction method thereof, comprising: a bridge deck 1, an installation mechanism, a damping mechanism and a watering mechanism.

[0048] Wherein, the installation mechanism is installed on the bridge deck 1, the shock absorbing mechanism is installed on the bottom of the installation mechanism, and the watering mechanism is installed on the installation mechanism.

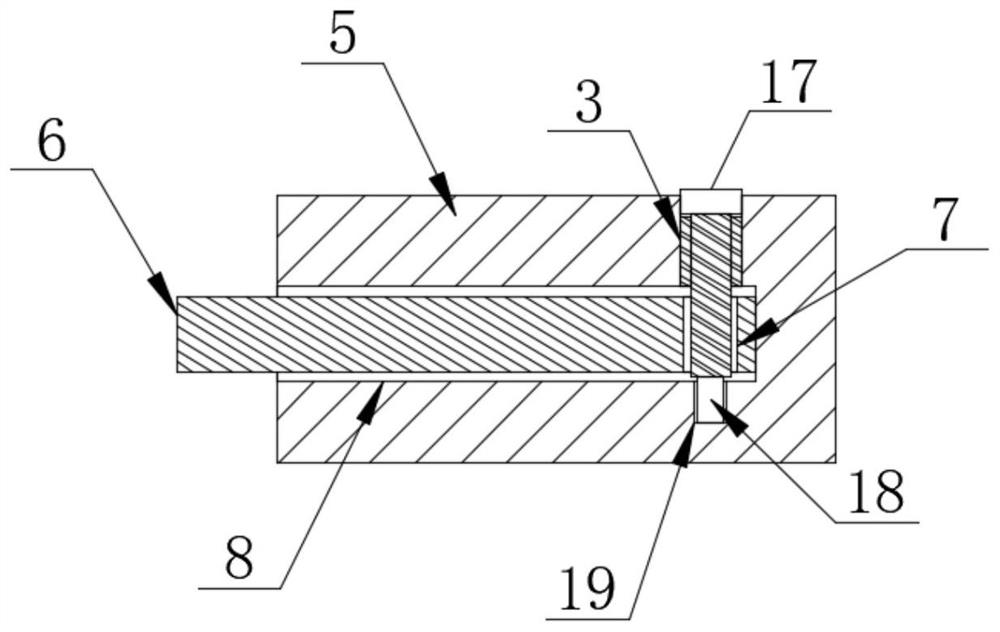

[0049] Among them, such as Figure 1-Figure 6 As shown, in order to complete the quick connection installation between multiple bridge structure bodies and increase the splicing efficiency of the bridge structure, the bridge installation mechanism is installed on the bridge deck 1. The installation mechanism includes a prefabricated convex beam 2 and a prefabricated concave beam 5. The bridge deck 1 One side of the bridge deck 1 is fixedly connected to the prefabricated c...

Embodiment 2

[0059] see Figure 1-Figure 6 , the present invention also provides a construction method for a prefabricated bridge structure in a tunnel, comprising the following steps:

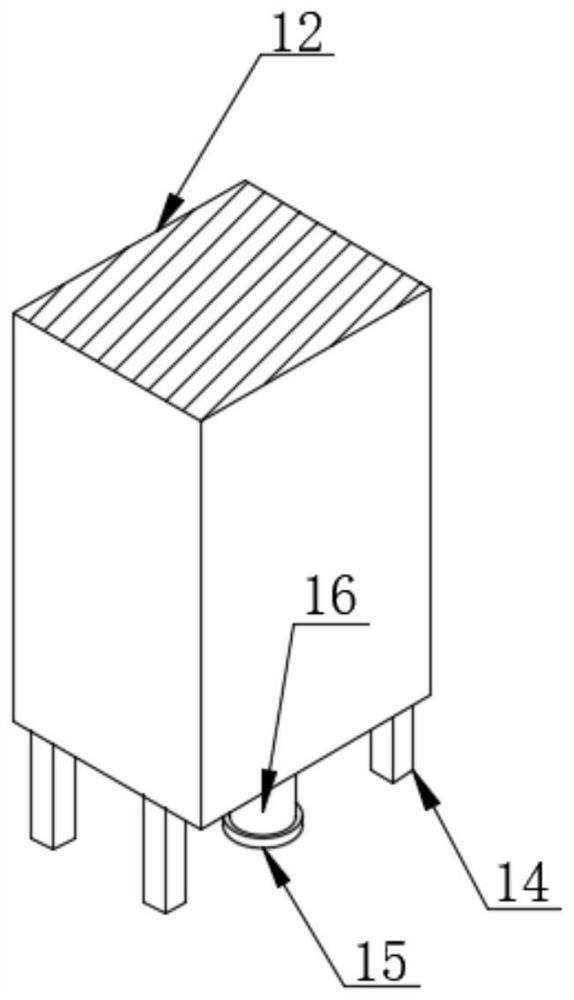

[0060] S1, the pier column 11 is placed on the installation place of the tunnel bridge, by pouring concrete at the bottom of the pier column 11, the concrete covers the inserting column 27, the first stirrup 26 and the second stirrup 28, and the guide column in the four pillars 12 14 and the movable column 16 are respectively slidably installed inside the second chute 21 and the first chute 20 of the pier column 11, so that the column 12 is installed on the pier column 11;

[0061] S2. After the pillars 12 are installed, install the prefabricated concave beam 5 on the top of two of the pillars 12 and the prefabricated convex beam 2 on the top of the other two pillars 12, and between the prefabricated concave beam 5 and the prefabricated convex beam 2 The bridge deck 1 is installed, and the support frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com