Precast beam type scissor stair and construction method thereof

A construction method and technology of prefabricated beams, applied in the direction of stairs, ladder-like structures, pedals, etc., can solve the problems of poor fire performance, excessive building materials, inconvenient transportation, etc., and achieve reduced usage, high durability and wear resistance , Excellent bending and cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

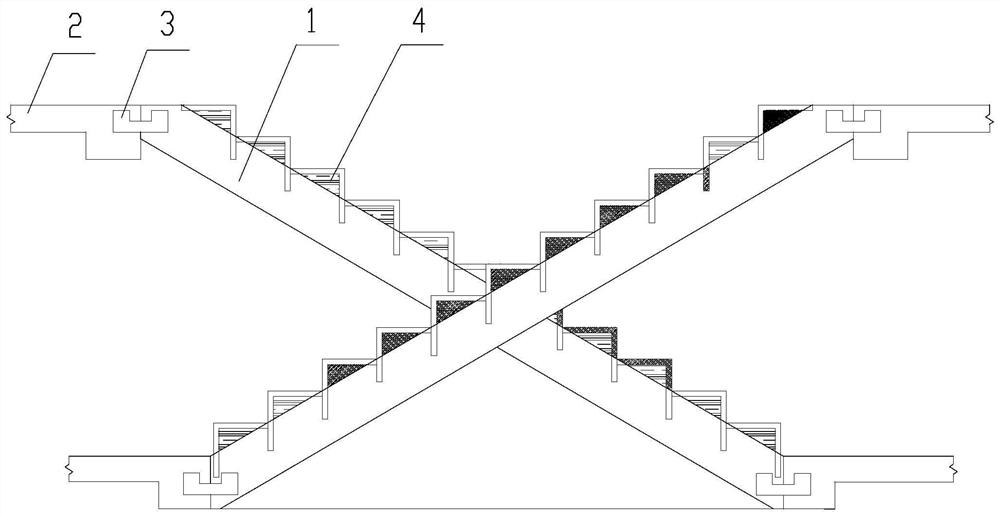

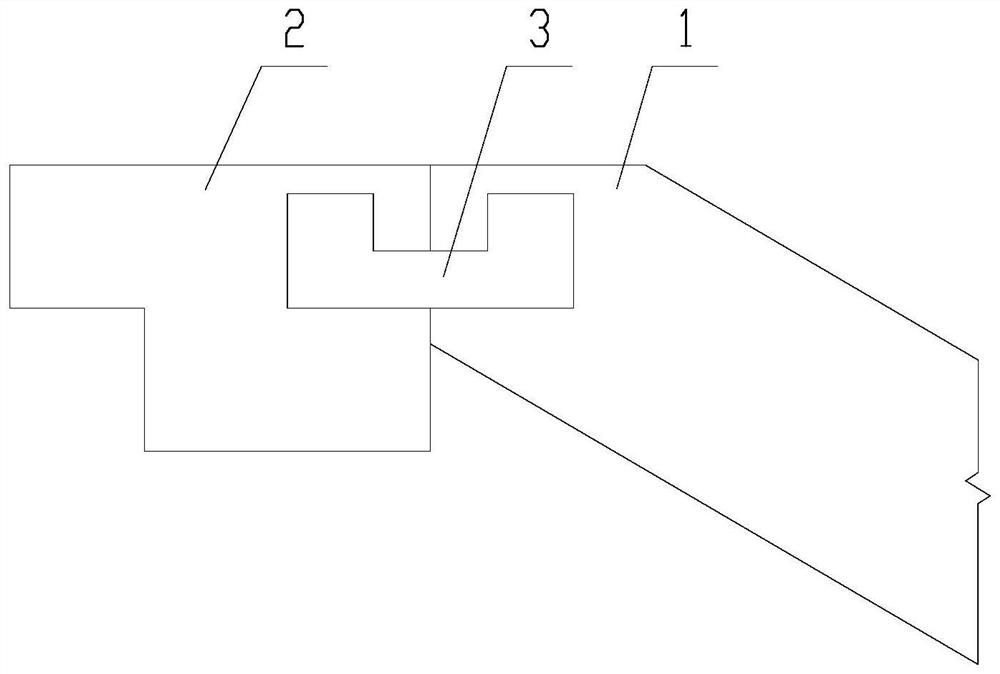

[0069] A prefabricated beam-type scissors staircase, comprising two reversely installed staircase bodies 1 and a beam-type platform slab 2, wherein:

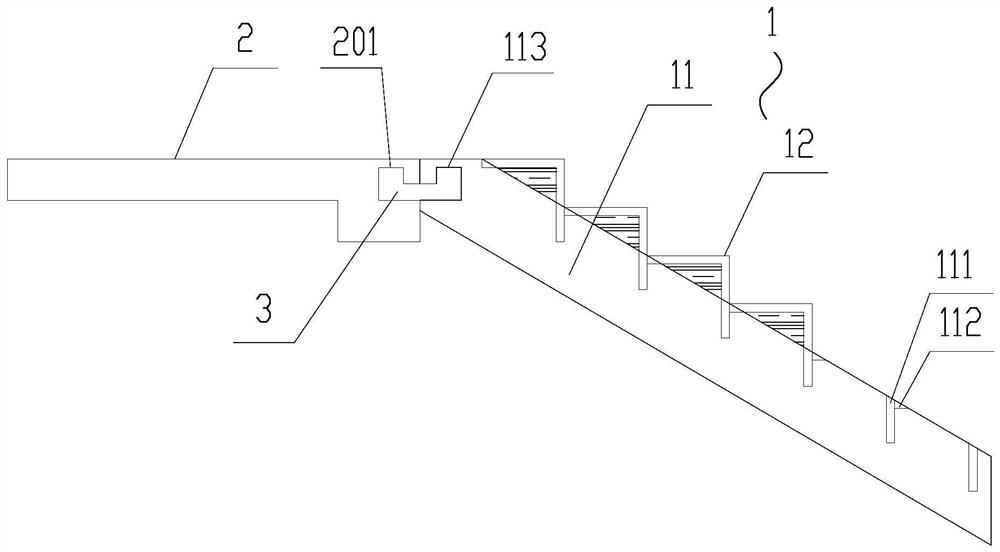

[0070] The stair body 1 includes a stair section 11 and an L-shaped tread plate 12. The front of the stair section is provided with a vertical step hole I111 and a flat hole I112 on the kick surface. In the hole I112, the vertical end of the L-shaped step plate 12 is installed in the step vertical hole I111 of the stair section 11. The ladder section 11 and the beam platform slab 2 are poured from prestressed tendons, reinforced mesh, ultra-high performance concrete, gypsum powder, and gypsum fibers. The volume ratio is: 1:1:0.004; and the hollow between the L-shaped step plate 12 and the step section 11 is filled with sound-absorbing material 4, and the sound-absorbing material 4 is made of ceramsite material or sponge material.

[0071] The beam-type platform slab 2 is fixedly connected to the wall, and the beam-type platform...

Embodiment 2

[0073] A prefabricated beam-type scissors staircase, its basic structure is the same as that of Embodiment 1, the difference is that: the staircase body 1 also includes a stair lengthening part 13, and the stair lengthening part 13 is made of prestressed tendons and reinforcement mesh , ultra-high performance concrete, gypsum powder, and gypsum fiber, the volume ratio between the ultra-high performance concrete, gypsum powder, and gypsum fiber is: 1:1:0.003; Stepping vertical hole II131; the tail of the ladder section 11 has a kicking surface flat hole II114, and the ladder section extension part 13 and the tail of the ladder section 11 pass through the L-shaped tread plate installed in the stepping vertical hole II131 and the kicking surface flat hole II114 12 connected together; it can effectively make up for the insufficient length of the ladder section caused by the calculation deviation. A reinforced steel plate 132 is pasted on the back side of the joint; and the hollow ...

Embodiment 3

[0081] A prefabricated beam-type scissors staircase, the basic structure of which is the same as that of Embodiment 2, the difference is that: the staircase also includes a beam 5 and a support column 6; one end of the beam 5 is connected to the wall, and the other end sequentially traverses the The two reversely installed stair sections are then fixed on the wall on the other side; the support column 6 is formed by pouring jacks and ultra-high performance concrete, the top of the support column 6 is connected to the back of the stair section, and the support column The bottom of 6 is fixed on the floor.

[0082] The specific structure of the prefabricated beam type scissors staircase described in the present embodiment three is as follows:

[0083] A prefabricated beam-type scissors staircase, including two reversely installed staircase bodies 1, beam-type platform slabs 2, beams 5 and support columns 6, wherein:

[0084] The stair body 1 includes a stair section 11, an L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com