Construction method of low-bearing-capacity soft rock tunnel

A construction method and technology of bearing capacity, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve the problems of continuous overall settlement, extrusion deformation, and self-stabilization of the face of the initial support, so as to improve the accuracy of construction. , The effect of simple construction and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

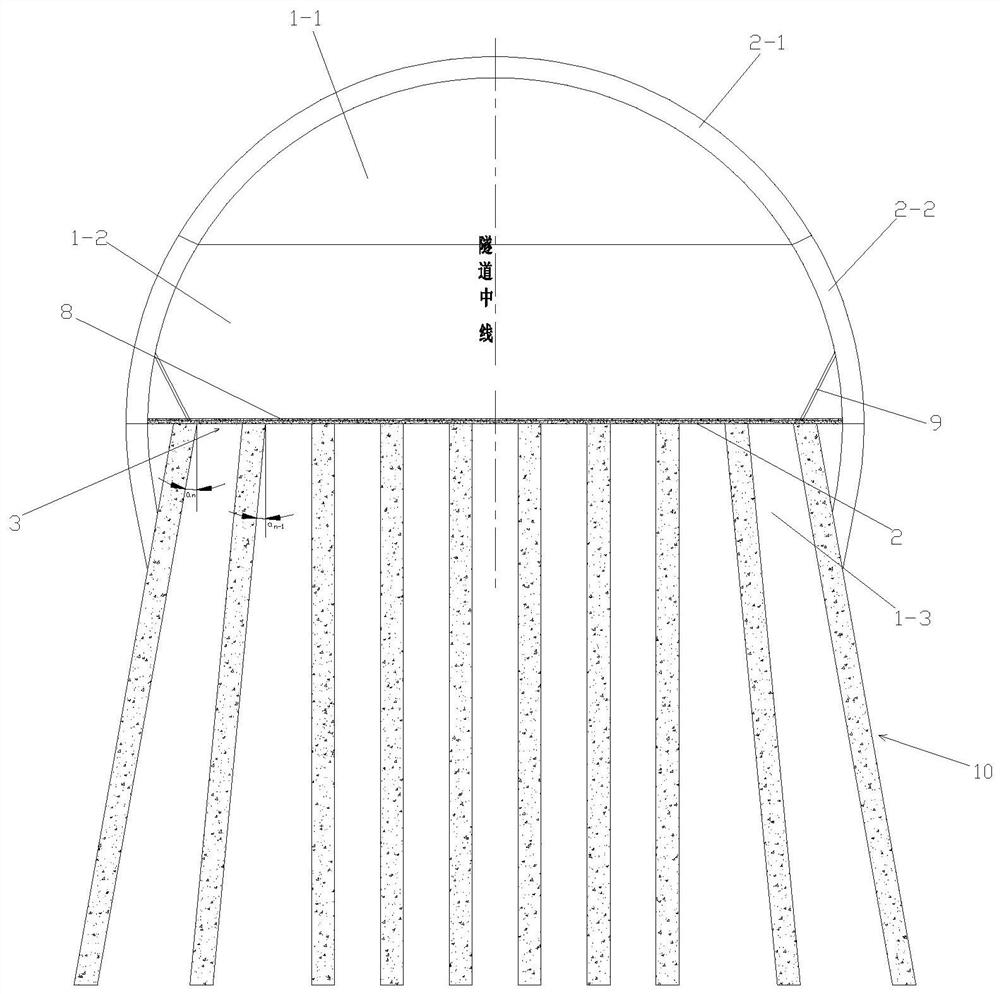

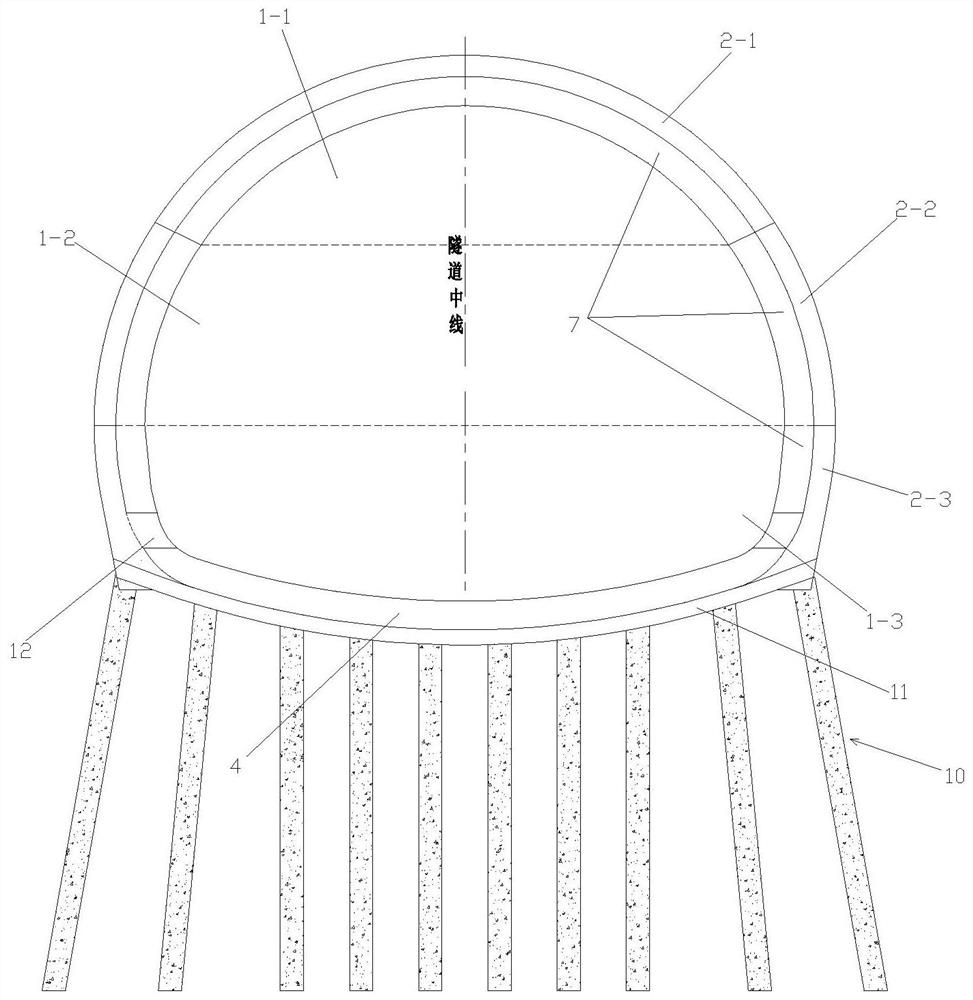

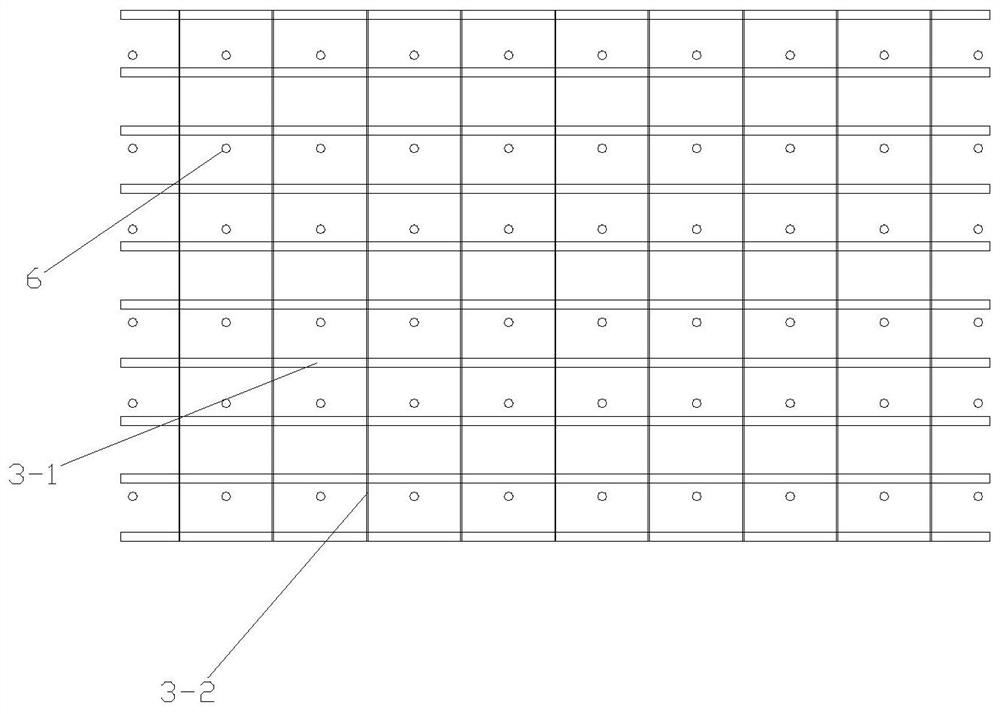

[0056] Such as Figure 1 to Figure 4 The construction method of a soft rock tunnel with low bearing capacity is shown, excavating the soft rock tunnel constructed along the longitudinal extension direction of the tunnel, and during the excavation process, the soft rock tunnel is reinforced with jet grouting piles at the middle steps Step and base, the method comprises the following steps:

[0057] Step 1. Upper step excavation and upper primary support:

[0058] Excavate the upper steps of the soft rock tunnel to be constructed, and simultaneously perform upper primary support 2-1 on the upper cave body 1-1 formed by the excavation of the upper steps during the excavation process of the upper steps;

[0059] Step 2. Temporary inverted arch waist beam structure construction of middle steps:

[0060] Step 201: Excavate the middle bench for the soft rock tunnel to be constructed, and simultaneously carry out the middle primary support 2-2 for the middle cave body 1-2 formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com