Sample loading device and analyzing and sorting equipment comprising same

A sampling device and sorting technology, which is used in the preparation of samples for testing, etc., can solve the problems of inability to realize the temperature of the sample mixture, the inability to maintain the activity of biological particles, and the low degree of automation, so as to reduce pollution or bacteria. The effect of improving the carrying rate, improving the analysis and sorting performance, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

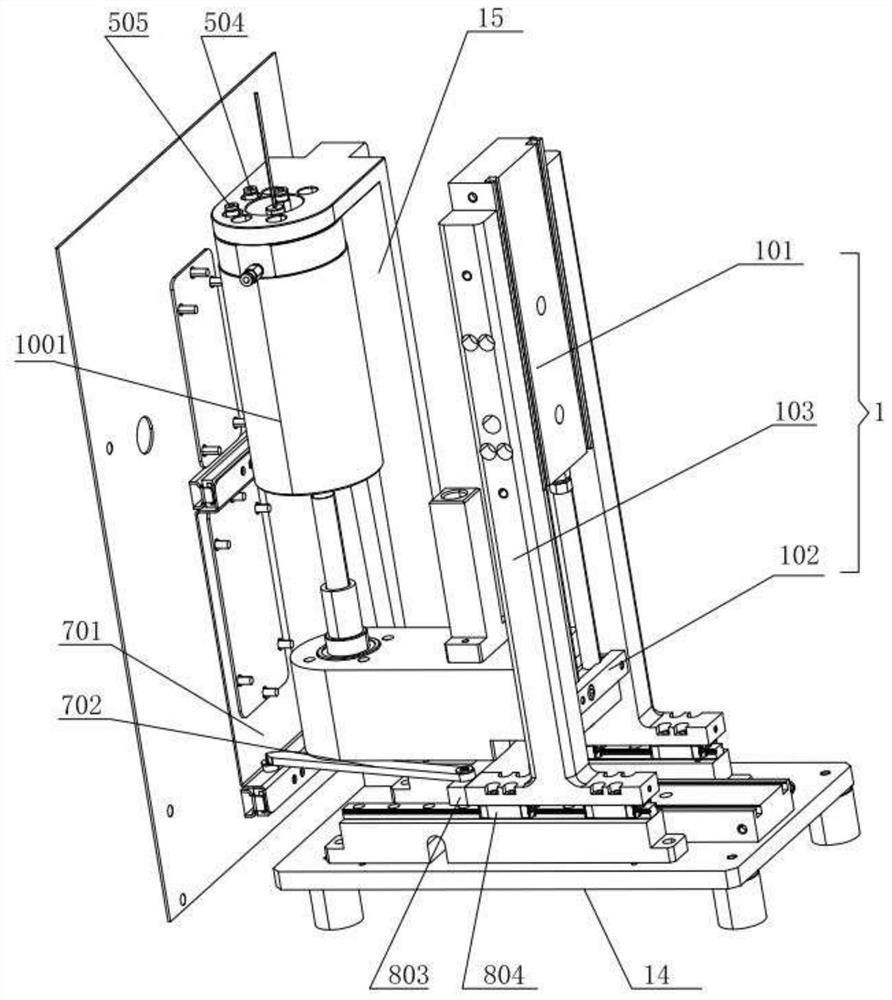

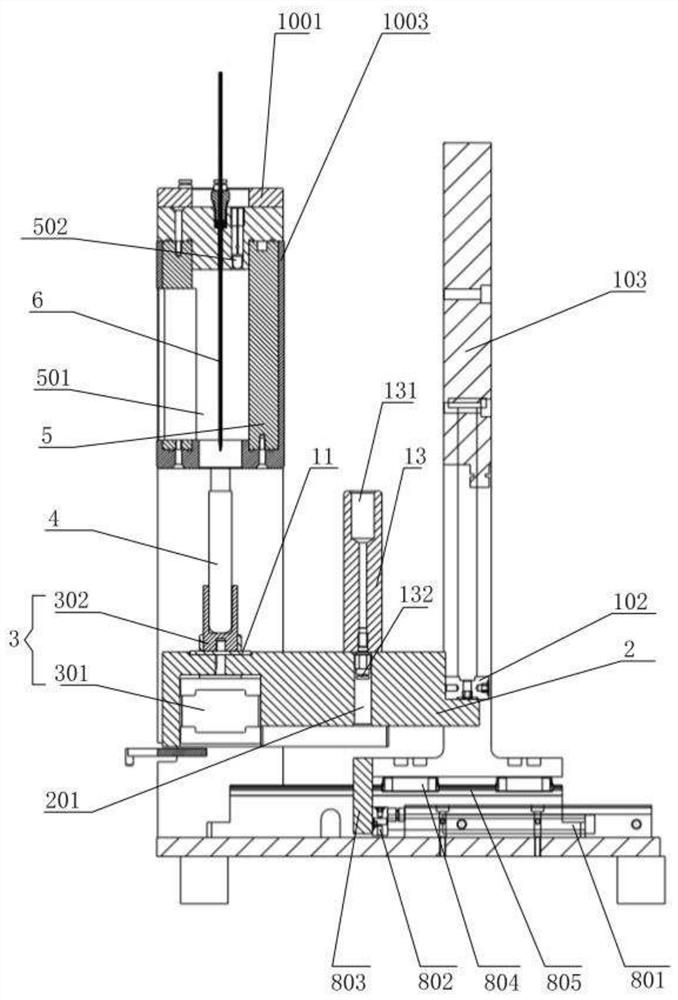

[0044] Please refer to figure 1The sample loading device in Embodiment 1 of the present invention includes a first drive device 1, a test tube carrier 2, a bin body 5, and a sample feeding device 6, the first drive device 1 is connected to the test tube carrier 2, and the test tube carrier 2 is used to carry the test tube 4, the interior of the test tube 4 can place the sample liquid, and the sample feeding device 6 is arranged in the chamber body 5.

[0045] Please refer to figure 1 and figure 2 , first describe the specific structure of the first driving device 1 as follows:

[0046] The first driving device 1 includes a first cylinder 101, the piston rod of the first cylinder 101 is connected with the first piston 102, and the first cylinder 101 can drive the piston rod and the first piston rod connected with the piston rod after ventilation. The piston 102 moves up and down in the vertical direction, wherein the movable stroke of the piston rod driven by the first cyli...

Embodiment 2

[0079] The second embodiment is mostly the same in structure and working process as the first embodiment, and the differences are as follows:

[0080] Please refer to Figure 10 , in order to realize that a part of the test tube carrier 2 is no longer suspended in the air and the installation is stable, in the second embodiment of the present invention, the first driving device 1 no longer drives the test tube carrier to move vertically, and the first driving device 1 drives the test tube carrier 2 moves in the horizontal direction, and the tail of the test tube carrier 2 is connected to the output end of the first driving device 1. Preferably, the first driving device 1 specifically adopts a cylinder and is arranged in the horizontal direction, wherein the first driving device 1 Several supporting bases 16 are arranged at the bottom to ensure the stability of the first driving device 1 . A pair of second guide rails 171 are connected to the bottom of the test tube carrier 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com