Flexible job shop scheduling method based on deep reinforcement learning and multi-agent graph

A technology of reinforcement learning and workshop scheduling, applied in machine learning, instruments, manufacturing computing systems, etc., can solve the problems of lack of specific details of machines and operations, too simple representation of factory production environment status, and difficulty in generating satisfactory scheduling solutions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

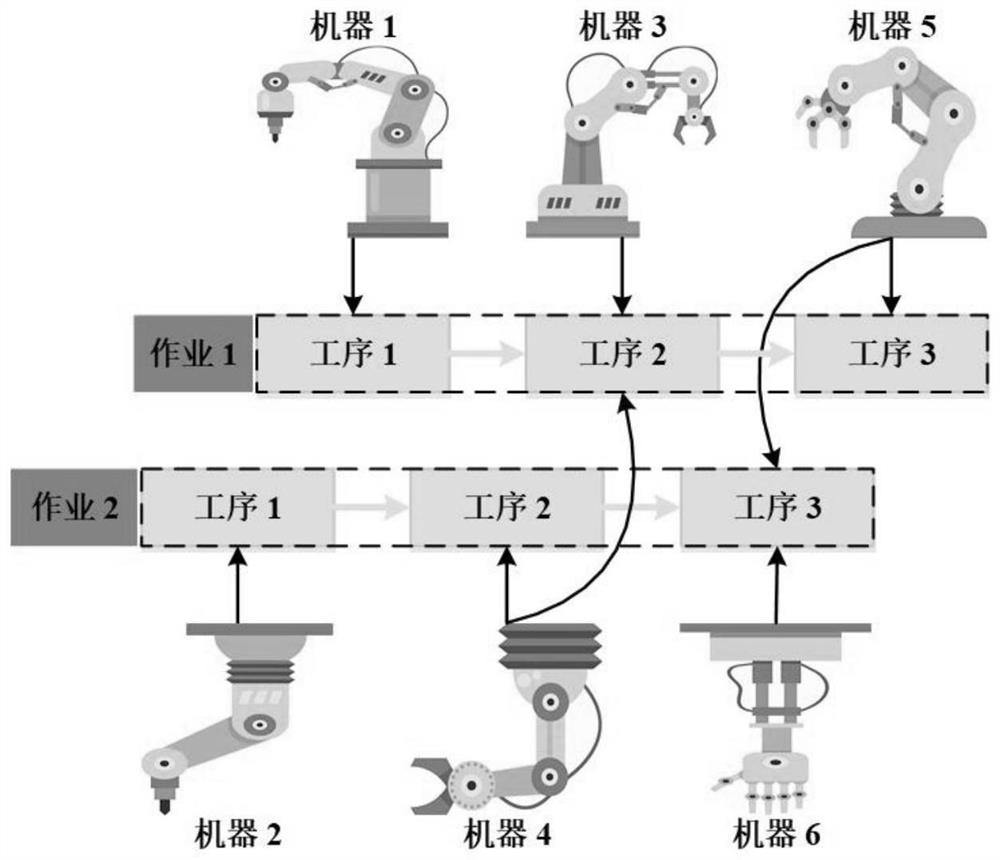

[0039] An embodiment of the present invention provides a flexible job shop scheduling method based on deep reinforcement learning and multi-agent graphs, including the following steps:

[0040] Step a. Associate each machine or each job with the agent of reinforcement learning, and build a multi-agent graph according to the process relationship between the machine and the job, including the process sequence between machines and the current process of the job, specifically through Build in the following way:

[0041] Definition 1 (multi-agent graph): Given a machine set M, a job set J, a machine set for each process k of each job j∈J They form a multi-agent graph G=(I, E s ,E u ,E v ,E w ), I is the node set, that is, the agent set:

[0042] I=M∪J; (1)

[0043] E. s is a set of directed edges between machines, representing the static relationship between adjacent processes of machines:

[0044]

[0045] E. u is the undirected edge set of machines and jobs, represen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com