Patents

Literature

61 results about "State representation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

State representatives, also known as congressmen and congresswomen, are elected officials who represent specific congressional districts within a state, defined by population. Representatives are elected to two-year terms. ... State representatives in Congress are responsible for creating an annual budget for the government. They may also authorize borrowing to cover budget short falls.

Dynamic device state representation in a user interface

InactiveUS20090217188A1Special data processing applicationsData selectionState dependentRemote system

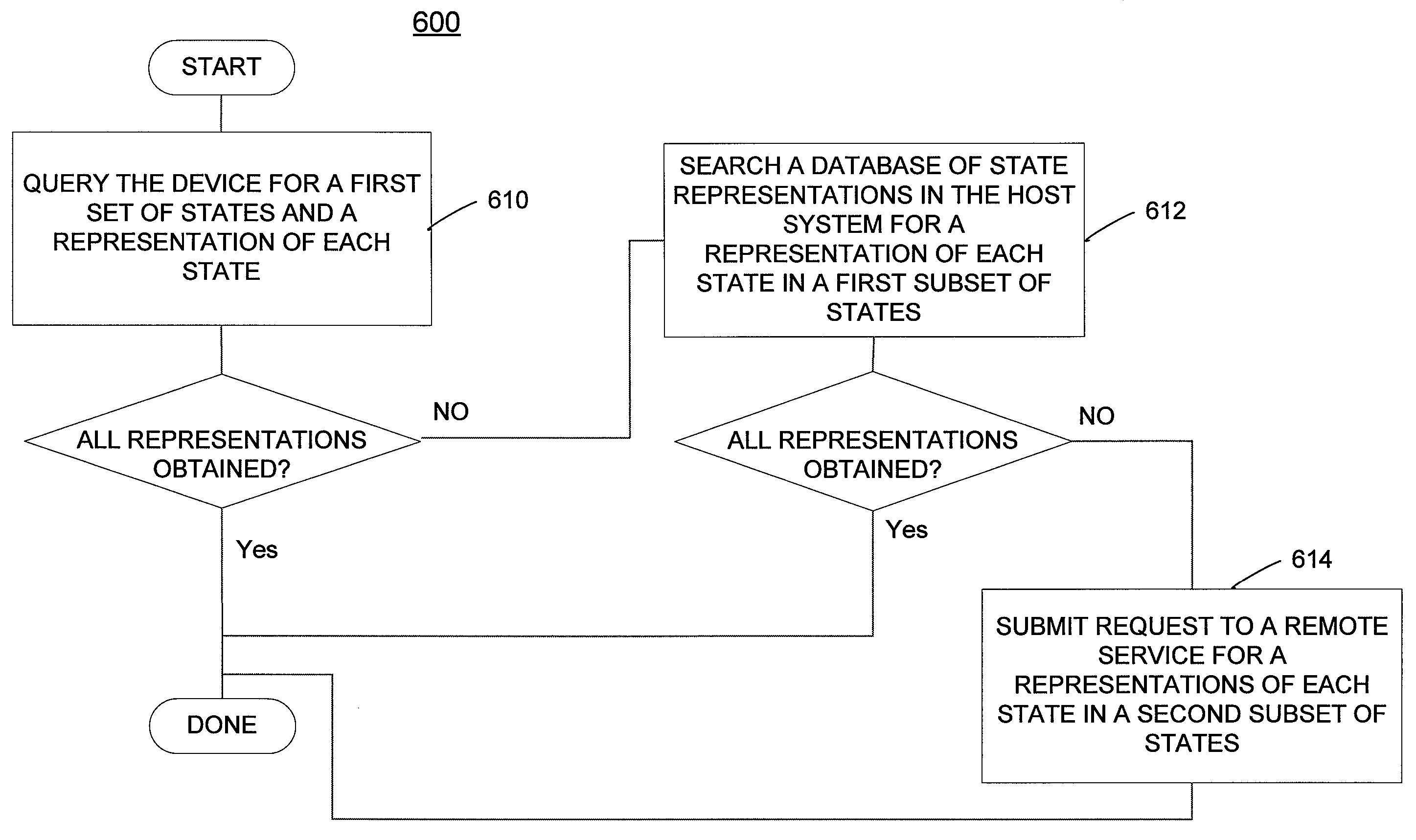

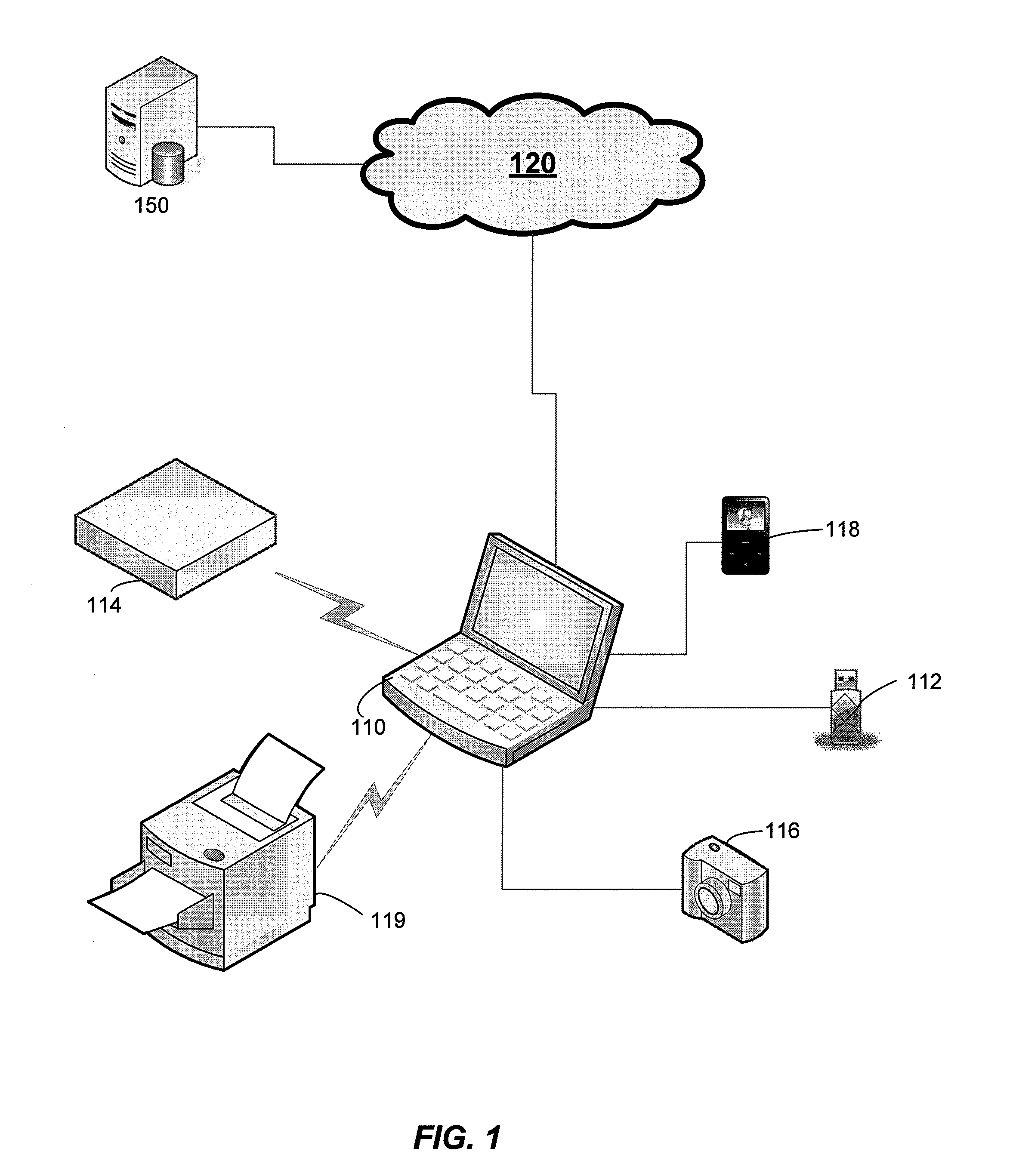

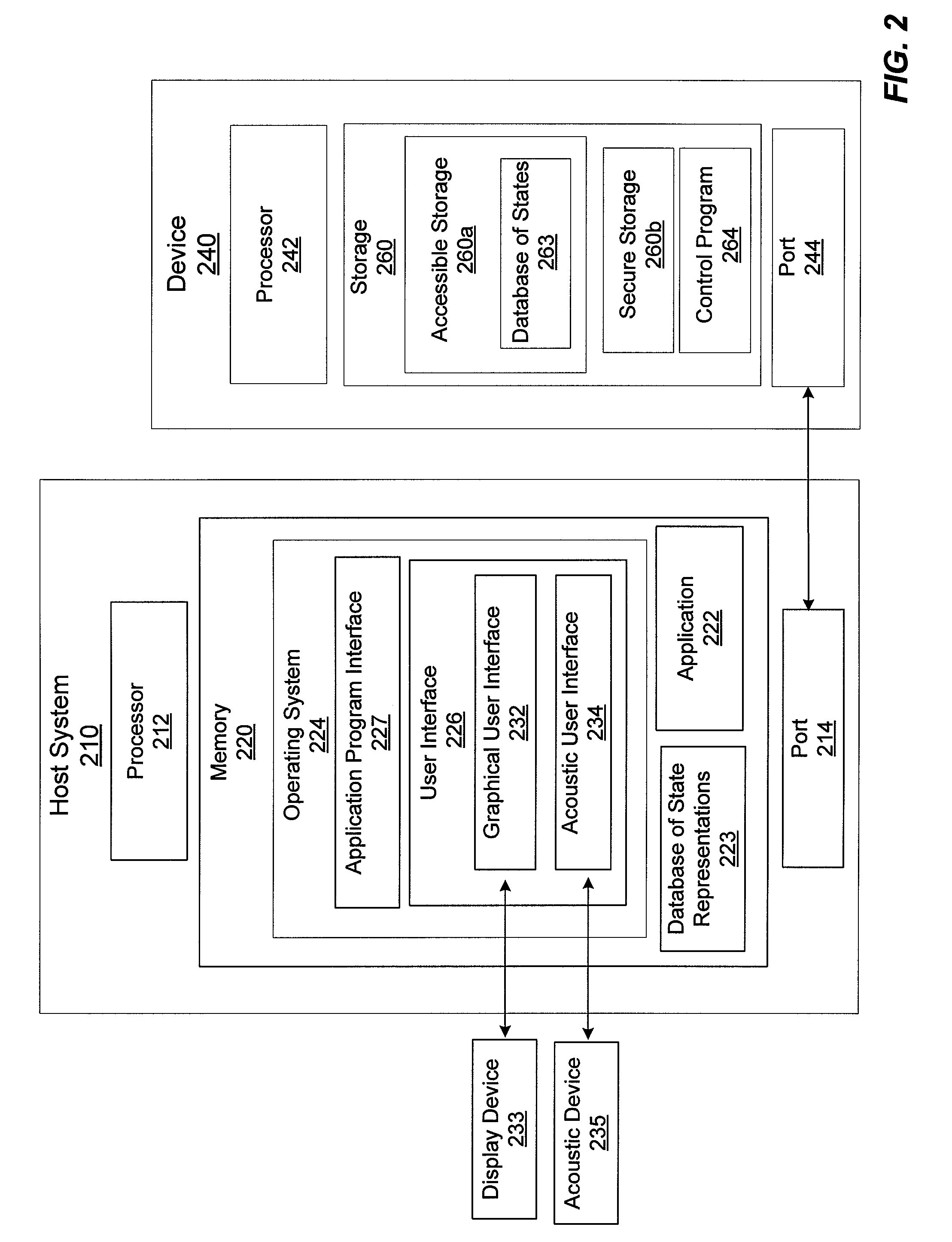

Processes for presenting a current state of a device having device storage connected with a host system are provided. In some processes, device manufacturers or vendors define a set of operational states of a device and provide user interface (UI) elements of a custom representation of each state through information stored in the device storage. Initially, the set of states of the device and UI elements associated with each state are received from the device storage. Information regarding a current state is received from the device, and a representation of the current state, which includes the received UI elements, is presented on the host system. In other processes, UI elements of a representation of each state are obtained from a remote system using device identification information. In other processes, UI elements from the device, from the host system, and / or from a remote system are combined to form a state representation.

Owner:MICROSOFT TECH LICENSING LLC

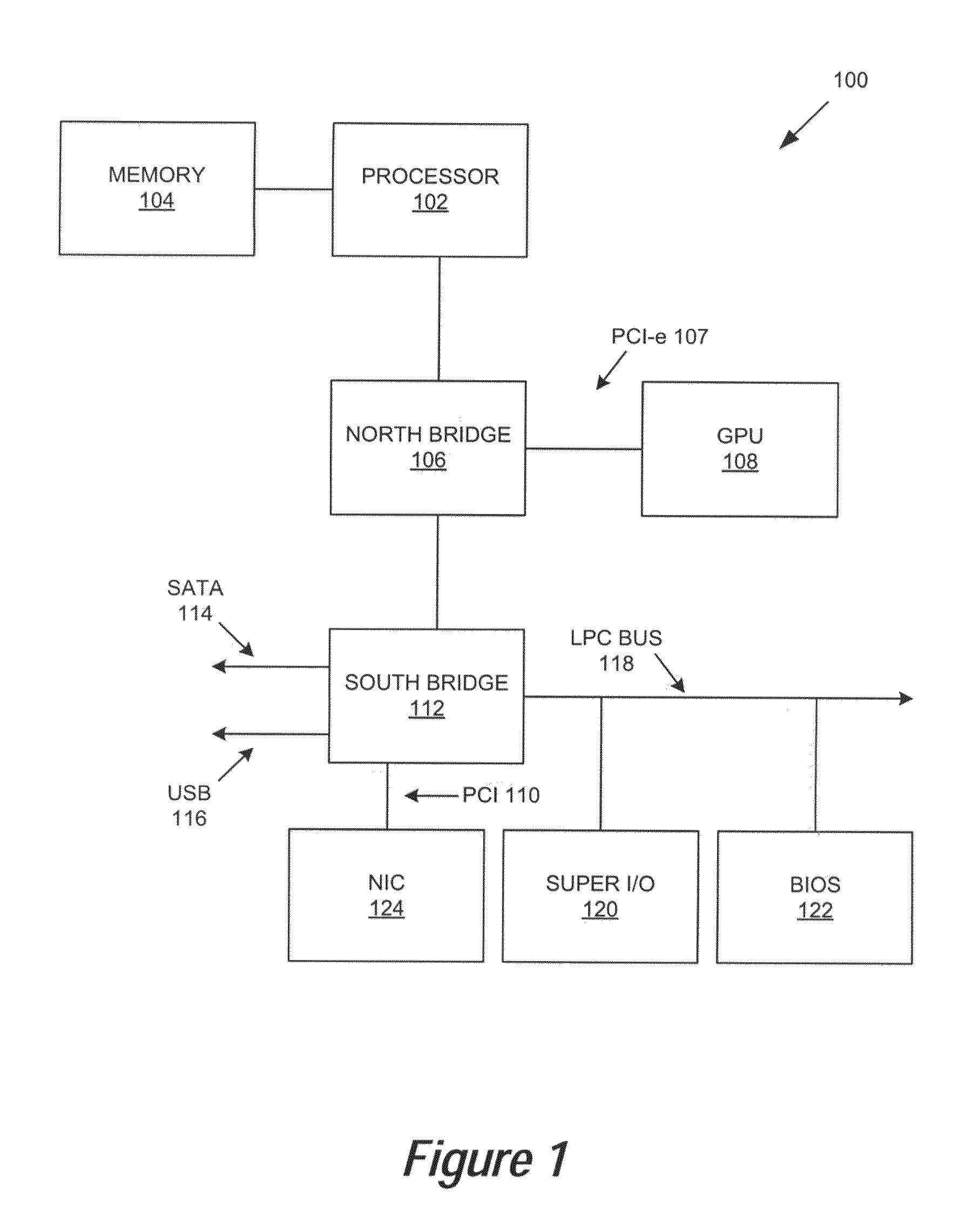

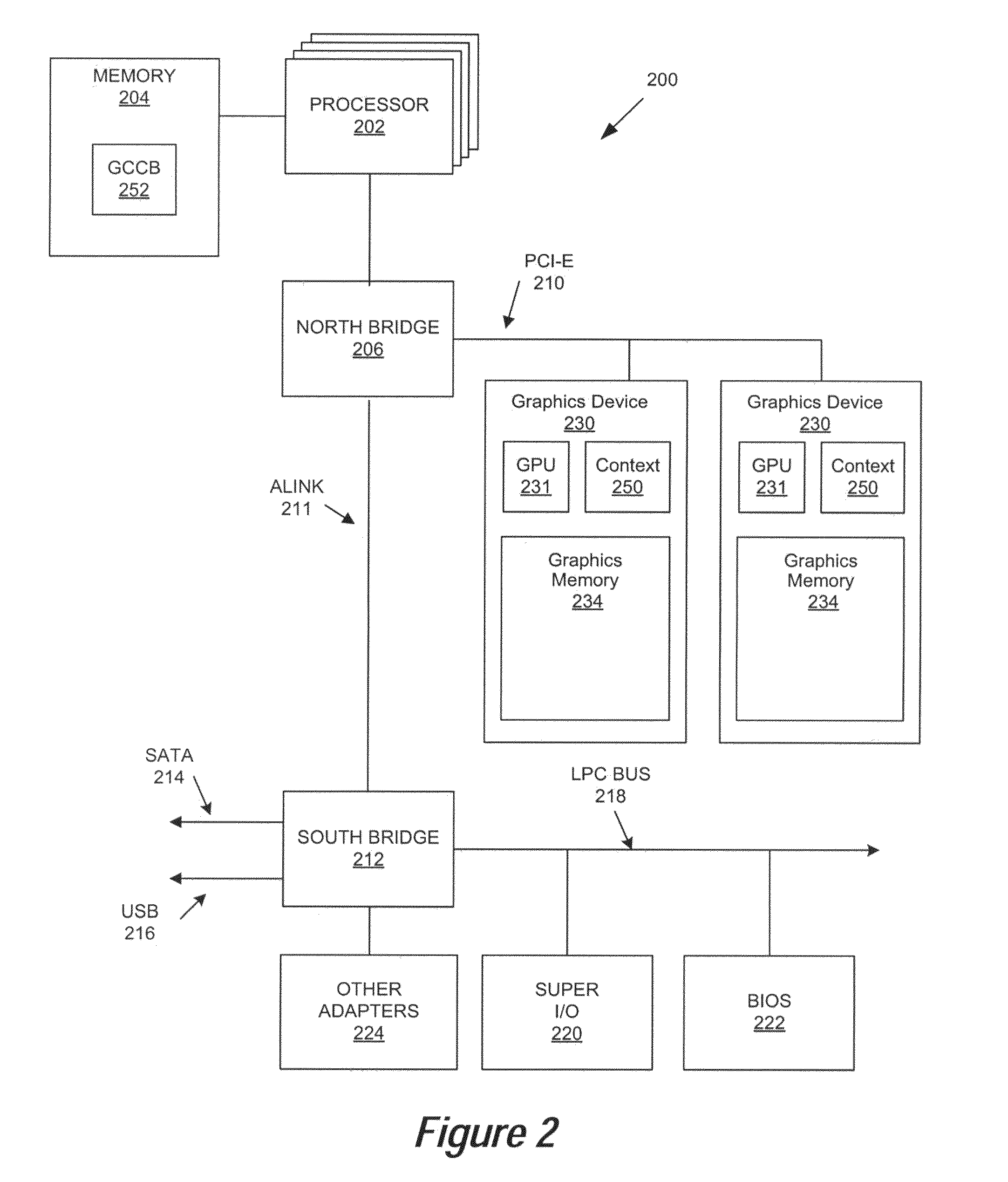

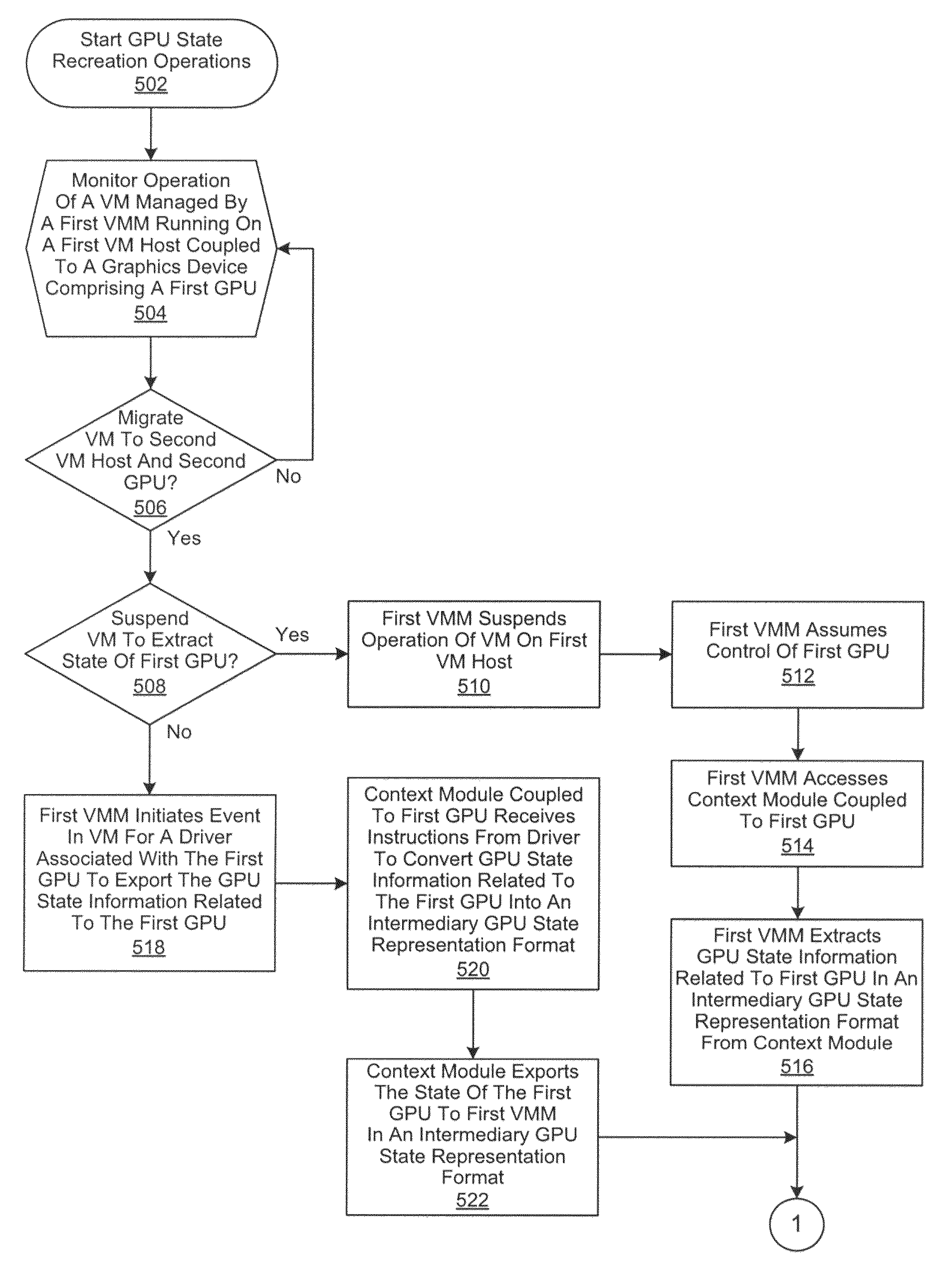

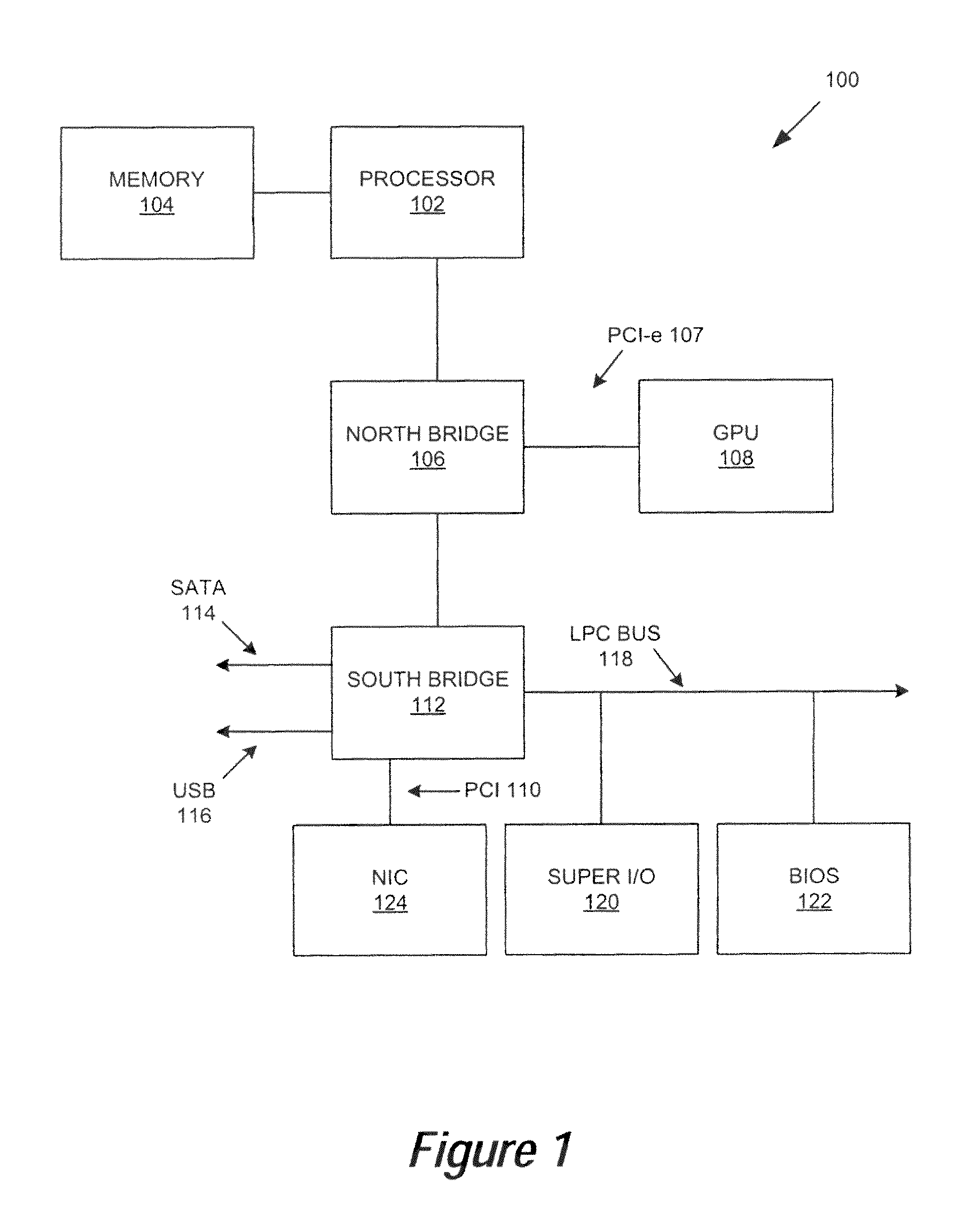

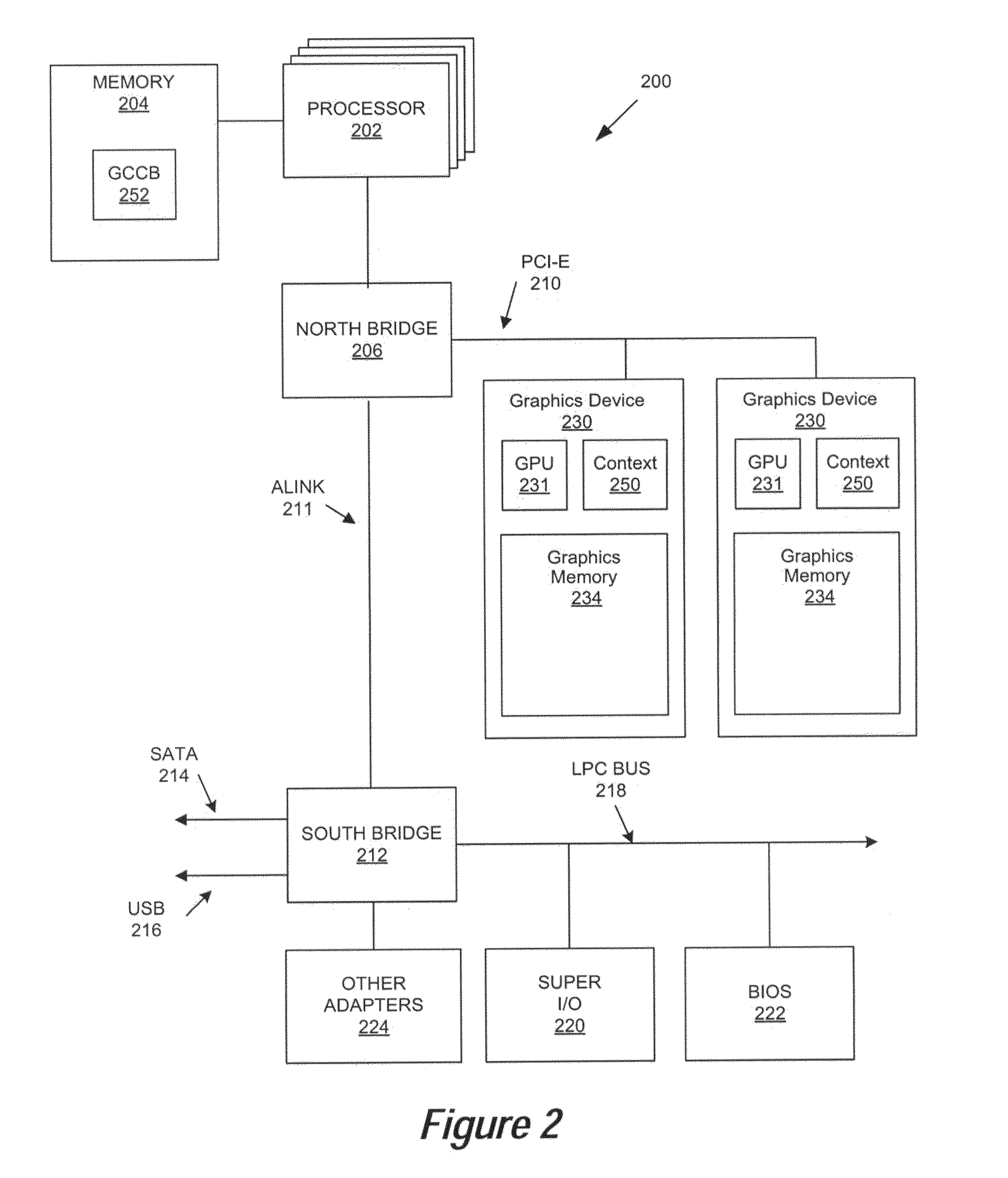

Saving, Transferring and Recreating GPU Context Information Across Heterogeneous GPUs During Hot Migration of a Virtual Machine

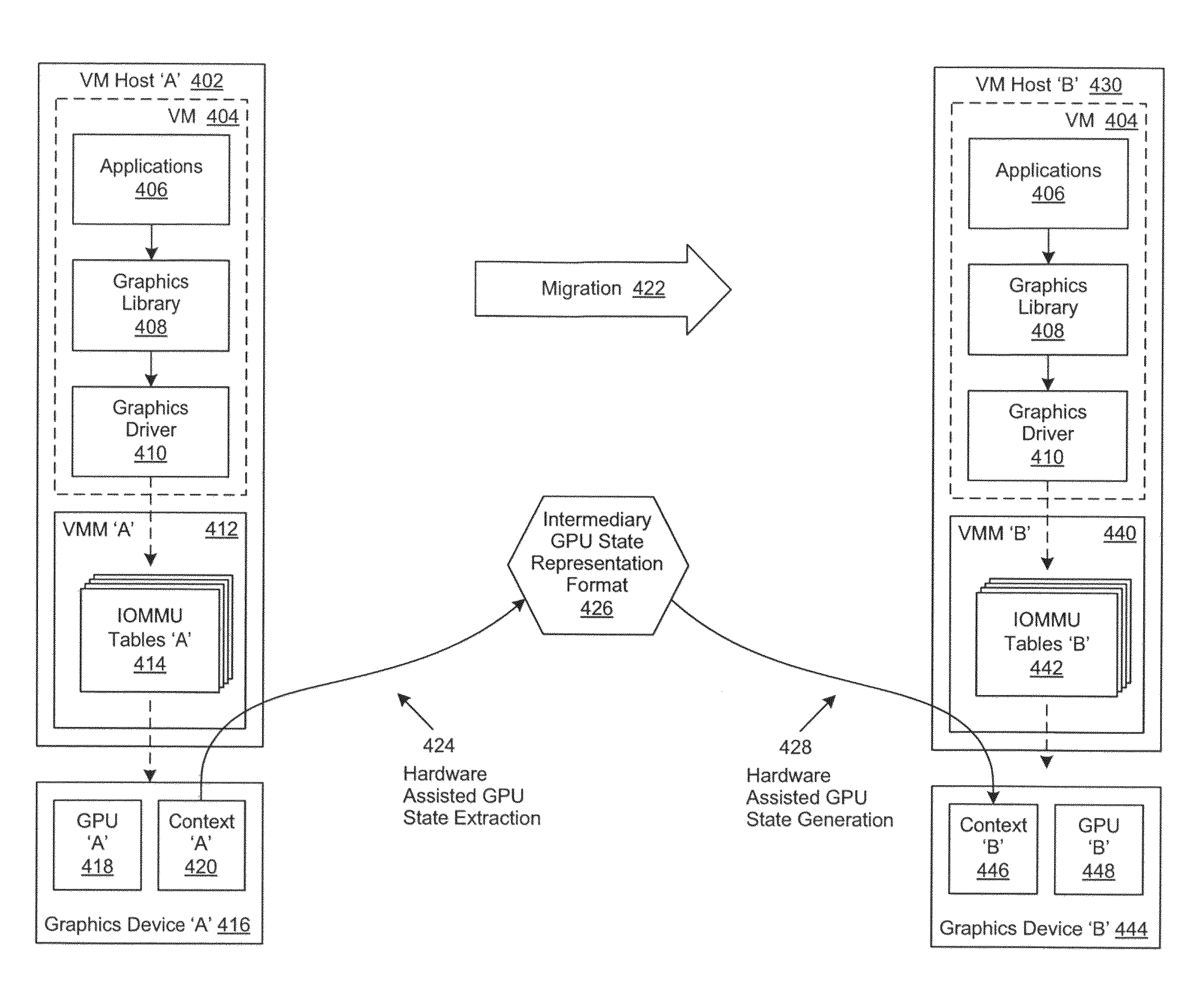

A system and method are disclosed for recreating graphics processing unit (GPU) state information associated with a migrated virtual machine (VM). A VM running on a first VM host coupled to a first graphics device, comprising a first GPU, is migrated to a second VM host coupled to a second graphics device, in turn comprising a second GPU. A context module coupled to the first GPU reads its GPU state information in its native GPU state representation format and then converts the GPU state information into an intermediary GPU state representation format. The GPU state information is conveyed in the intermediary GPU state representation format to the second VM host, where it is received by a context module coupled to the second GPU. The context module converts the GPU state information related to the first GPU from the intermediary GPU state representation format to the native GPU state representation format of the second GPU. Once converted, the GPU state information of the first GPU is restored to the second GPU in its native GPU state representation format.

Owner:ADVANCED MICRO DEVICES INC

State self-checking method of combined speed measuring and positioning system for train

ActiveCN101949955AImprove status detection performanceReduce redundant modulusWave based measurement systemsTesting/calibration of speed/acceleration/shock measurement devicesTransfer modelRadar

The invention provides a state self-checking method of a combined speed measuring and positioning system for a train, which comprises the following steps: judging the state of a speed sensor by using the respective multi-path information of the speed sensor for carrying out the redundant check; judging the measuring state of the speed sensor by taking radar measuring data as reference; judging the measuring state of a radar sensor according to the measuring data of the speed sensor and the output state word of a radar; and determining a system structure reconstruction scheme based on a system state transfer model according to the state judging results of the speed sensor and the radar, outputting speed measuring and positioning information which does not contain invalid or fault sensor or radar measuring results, and giving system state information representation or giving state representation of invalid measuring output when all sensors are invalid. The method of the invention improves the state detection performance of the sensors, reduces the complexity of the combined system, and can further save the engineering expenses and the maintenance cost.

Owner:TRAFFIC CONTROL TECH CO LTD

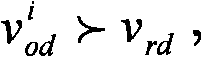

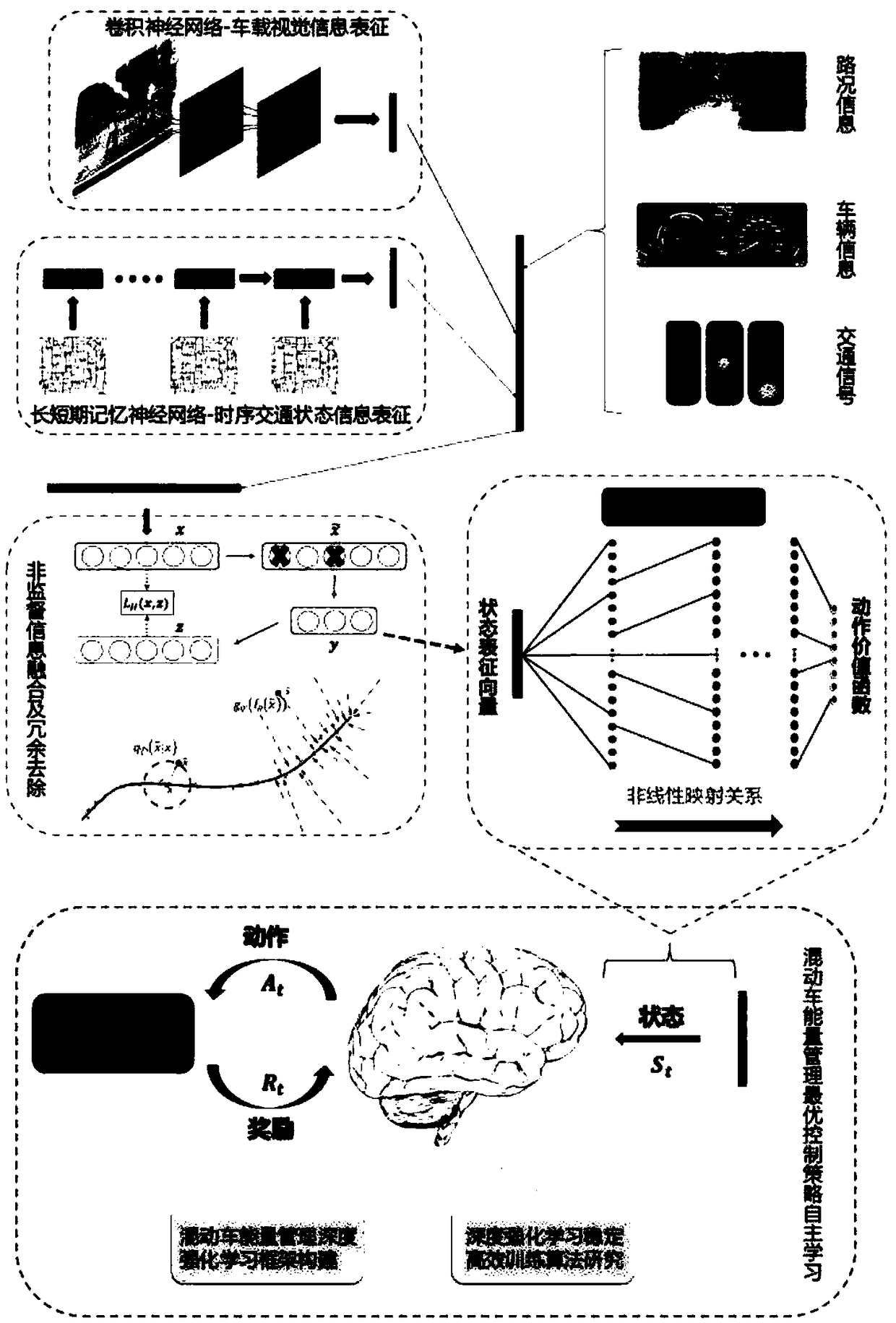

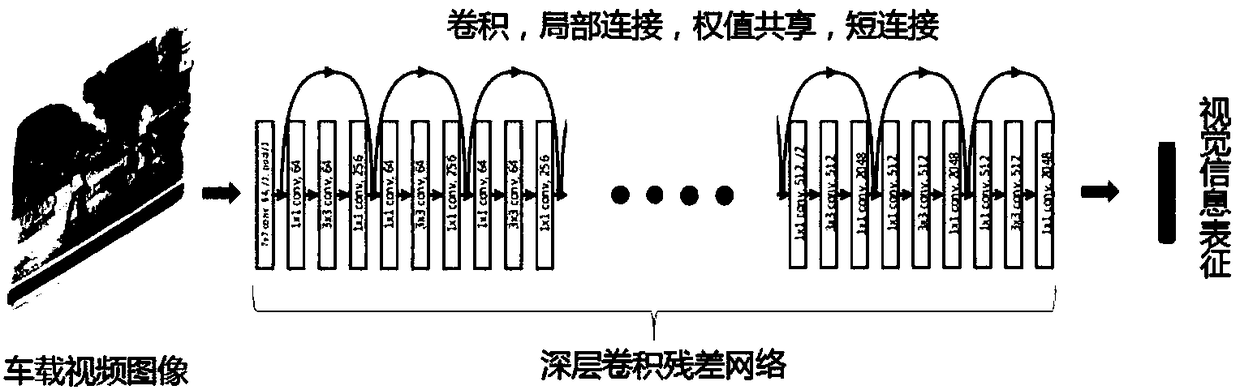

Plug-in hybrid electric vehicle energy management method based on deep reinforcement learning

ActiveCN108427985ATap into energy-saving potentialForecastingNeural architecturesDimensionality reductionState representation

The invention puts forward a plug-in hybrid electric vehicle energy management method based on deep reinforcement learning. The method comprises the following steps that: carrying out representation extraction on multisource high-dimension driving working condition information, and processing the high-dimension driving working condition information into a low-dimension representation vector; utilizing a redundant information rejection algorithm to carry out dimensionality reduction and fusion processing on obtained working condition state representation, including a low-dimensional representation vector, the own state information of a vehicle, a gradient and the like, to obtain low-dimensional continuous working condition information; constructing a plug-in hybrid electric vehicle energy management framework based on the deep reinforcement learning, and inputting the low-dimensional continuous working condition information to finish offline training; and utilizing a trained strategy tocontrol energy distribution, providing an approach for comprehensively considering the influence of multisource high-dimensional driving working condition information on a plug-in hybrid electric vehicle energy management effect, and utilizing a reinforcement learning autonomic learning optimal energy distribution scheme to mine the energy saving potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Saving, transferring and recreating GPU context information across heterogeneous GPUs during hot migration of a virtual machine

A system and method are disclosed for recreating graphics processing unit (GPU) state information associated with a migrated virtual machine (VM). A VM running on a first VM host coupled to a first graphics device, comprising a first GPU, is migrated to a second VM host coupled to a second graphics device, in turn comprising a second GPU. A context module coupled to the first GPU reads its GPU state information in its native GPU state representation format and then converts the GPU state information into an intermediary GPU state representation format. The GPU state information is conveyed in the intermediary GPU state representation format to the second VM host, where it is received by a context module coupled to the second GPU. The context module converts the GPU state information related to the first GPU from the intermediary GPU state representation format to the native GPU state representation format of the second GPU. Once converted, the GPU state information of the first GPU is restored to the second GPU in its native GPU state representation format.

Owner:ADVANCED MICRO DEVICES INC

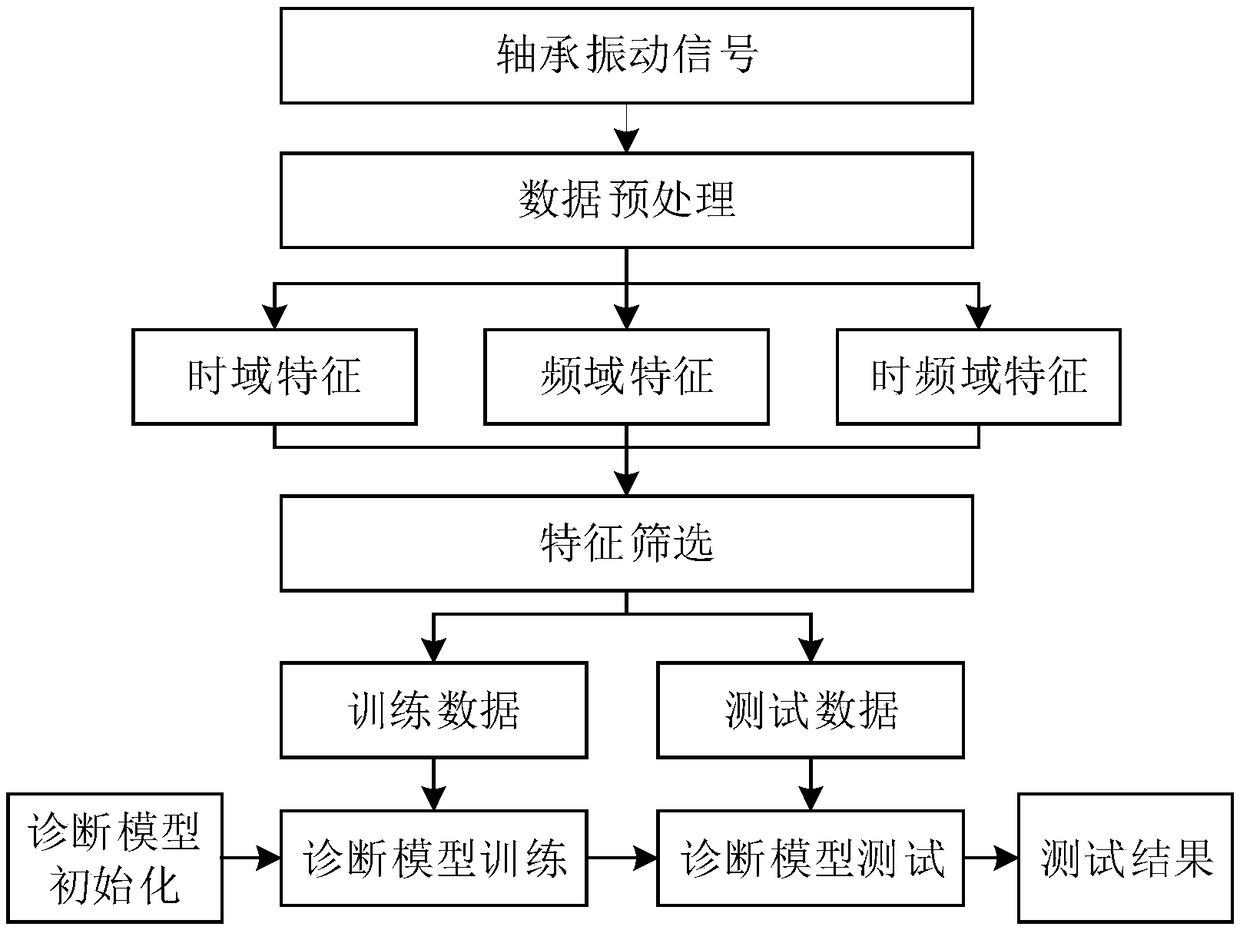

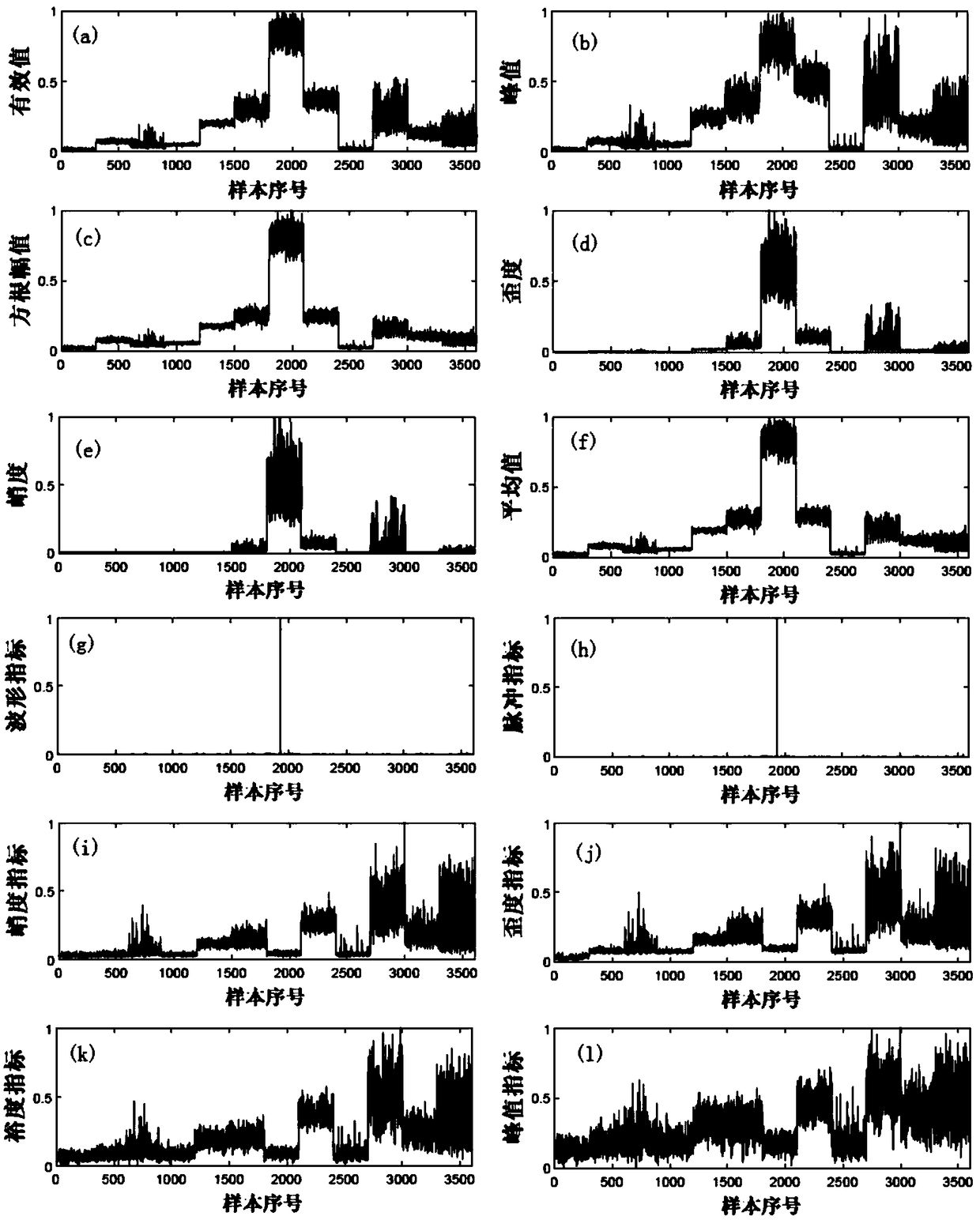

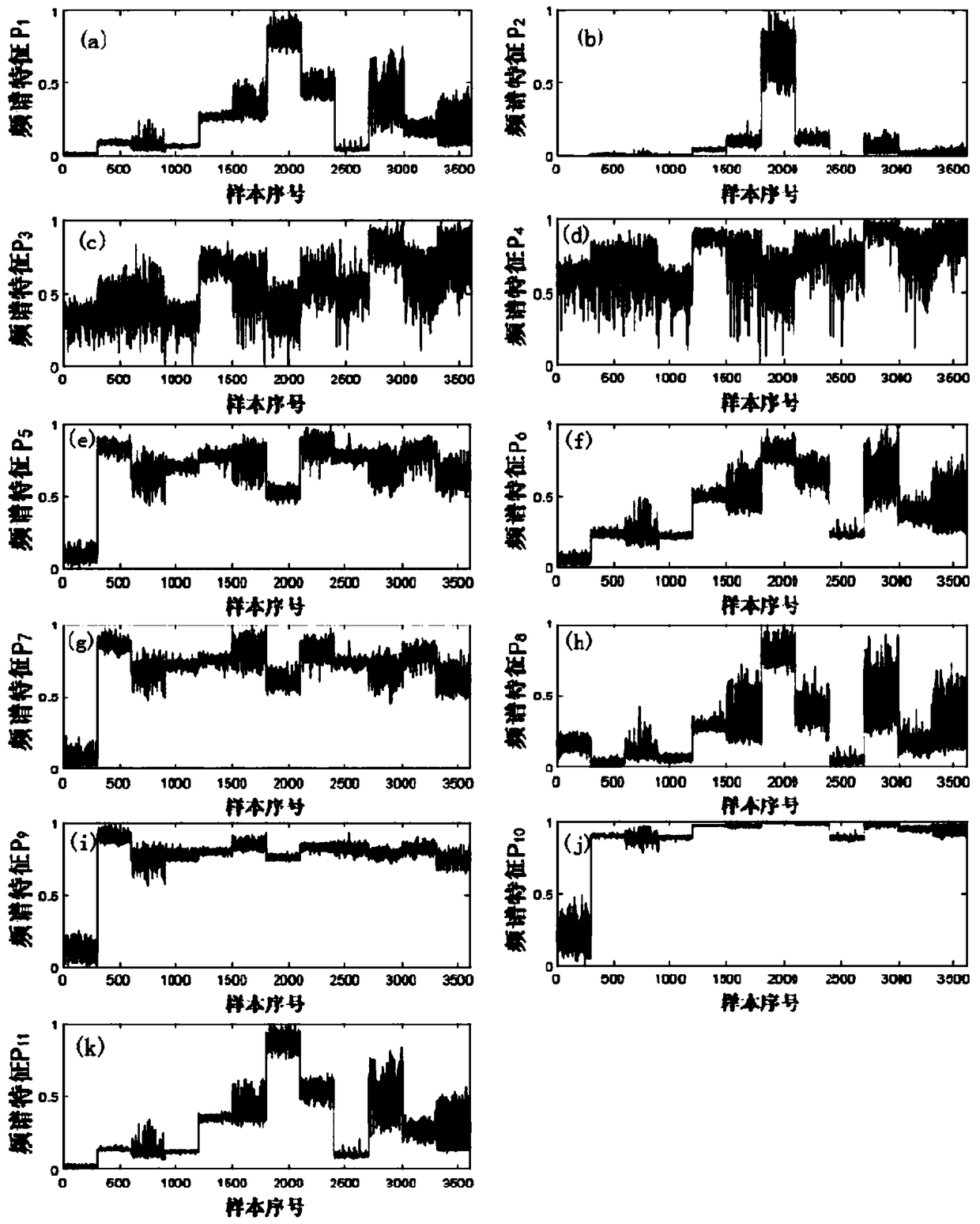

Rolling bearing fault diagnosing method and equipment based on CEEMDAN and CFSFDP

InactiveCN109100143AOvercome Mode Aliasing PhenomenonImprove adaptabilityMachine bearings testingTime domainTest sample

The invention discloses a rolling bearing fault diagnosing method and equipment based on CEEMDAN and CFSFDP, belonging to the field of fault diagnosis of rotary machines. The method comprises the steps of acquiring vibration signals of a bearing in a normal state and different fault mode states so as to obtain sample points of the vibration signals of different states, decomposing by using CEEMDANto obtain time and frequency domains characteristics of bearing diagnosis and screening out bearing state representation parameters along with the time domain and frequency domain characteristics, dividing the representation parameters into training samples and a test samples, then using a table CFSFDP algorithm as a bearing fault diagnosis model, inputting the training samples into the bearing fault diagnosis model, clustering output results, obtaining clustering amount, clustering center points of each type, and state types corresponding to the clustering center points, and inspecting the trained diagnosis model by using test samples. The method and equipment can identify different bearing fault types and fault degrees accurately and effectively.

Owner:HUAZHONG UNIV OF SCI & TECH

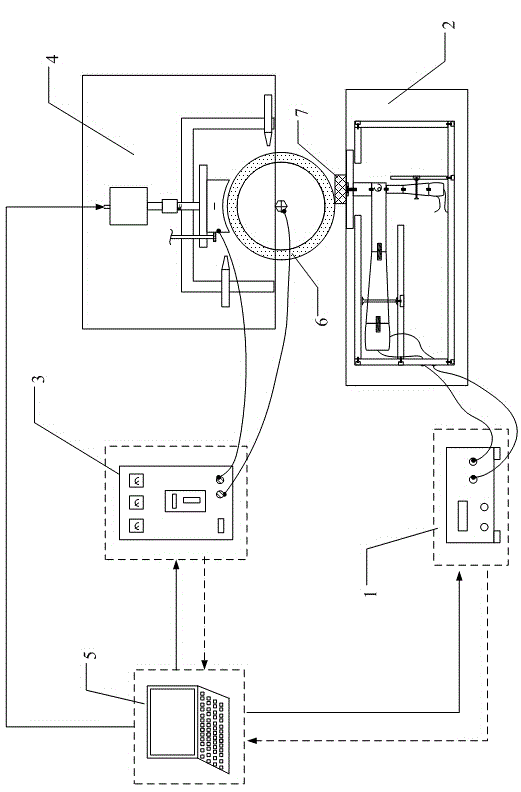

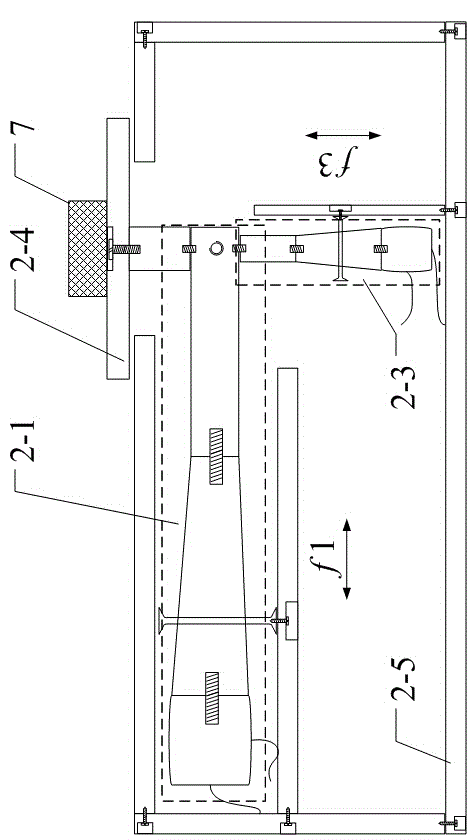

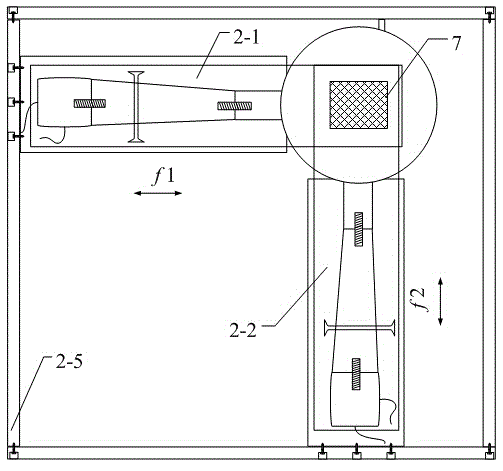

Ultrasonic 3D vibration and ELID (Electrolytic In-process Dressing) combined precision grinding system and method

ActiveCN104526471AGood effectProtruding uniform outer layer of sharpening abrasive grainsUltrasonic cavitationSingle process

The invention provides ultrasonic 3D vibration and ELID (Electrolytic In-process Dressing) combined precision grinding system and method. The grinding system comprises a multi-channel ultrasonic generator, an ultrasonic objective table, an automatic distance adjusting electrode, a high frequency DC pulse power supply and a computer monitoring system; the computer monitoring system is used for synchronously acquiring ELID and 3D ultrasonic vibration state representation signal, observing the working state and mutual influence degree of each combination process, and then automatically or manually performing feedback control, so as to enable the two processes to be dynamically harmoniously and optimally matched; when in grinding and processing, a grinding wheel contacts with the grinding surface of a workpiece to cause an electrolyte ultrasonic cavitation phenomenon which can effectively prompt the actual grinding effect of the grinding wheel, and the grinding force is stable. According to the system and method, the ultrasonic grinding processing technology and the ELID grinding technology are combined and supplement each other in advantages, so as the overcome the defects of single process; the technical support is provided for the application of the efficient processing of ultra-smooth surface of a hard and brittle material in the high-tech fields such as national defense and aerospace.

Owner:KEYIZHAN INTELLIGENT EQUIP CO LTD +1

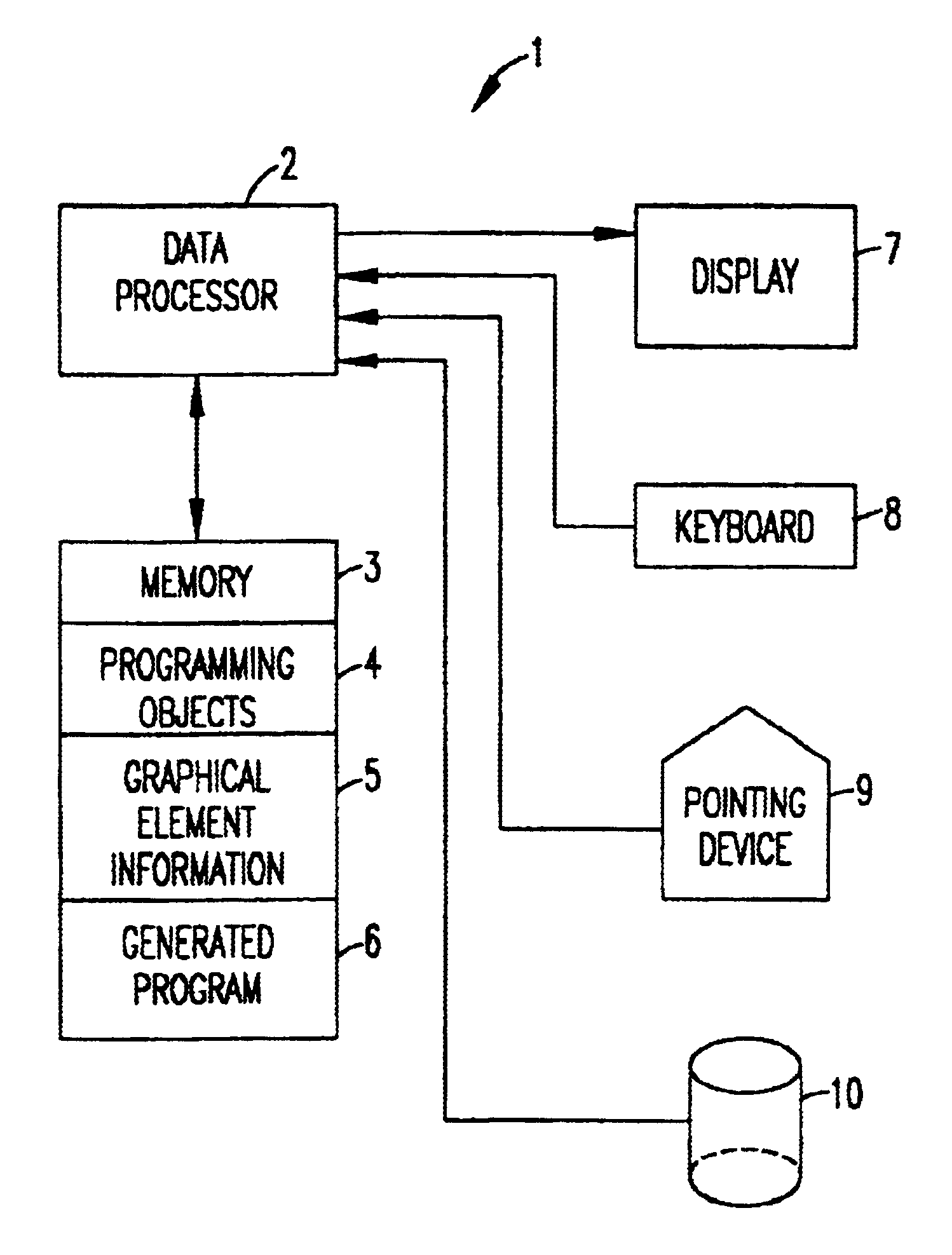

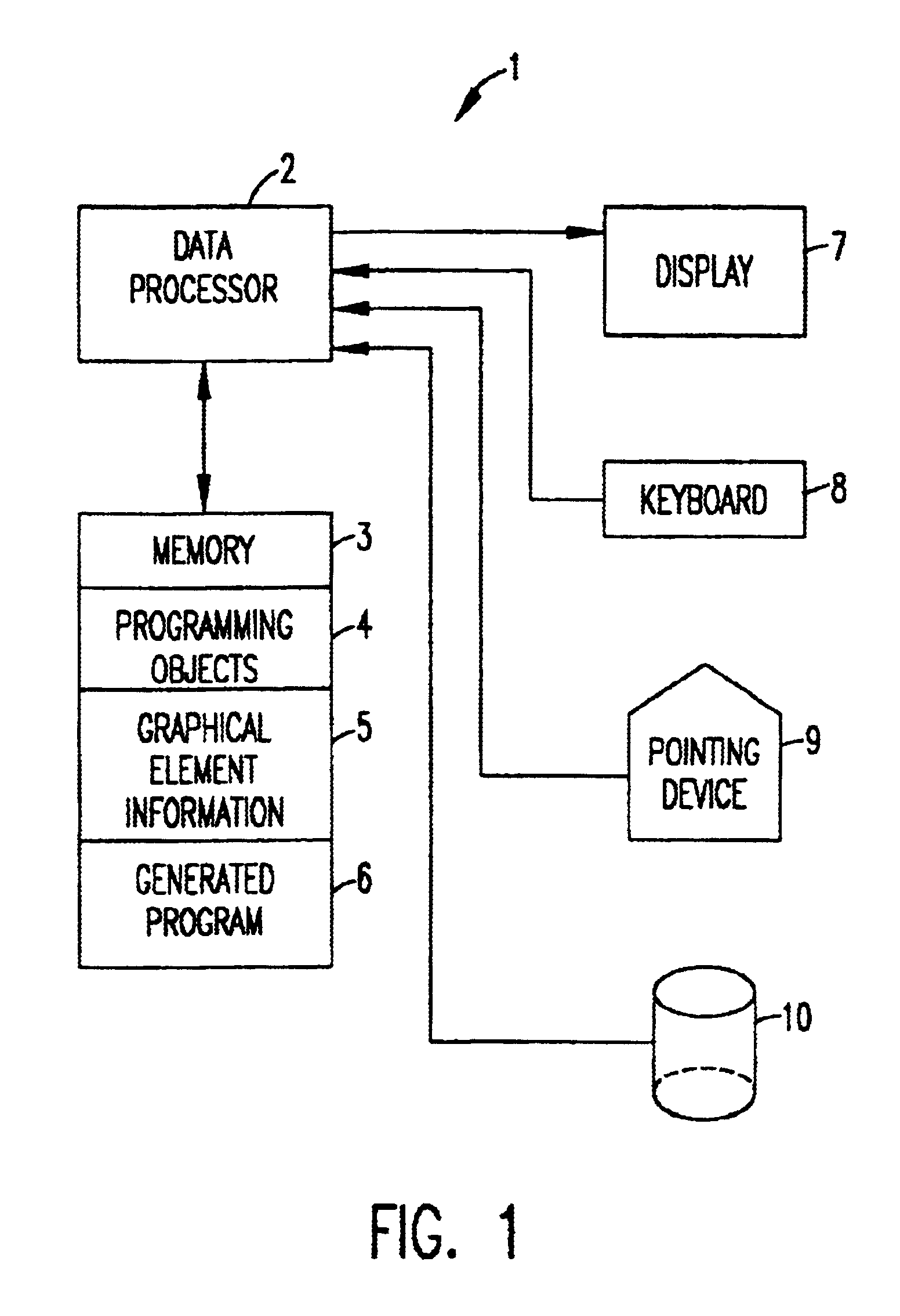

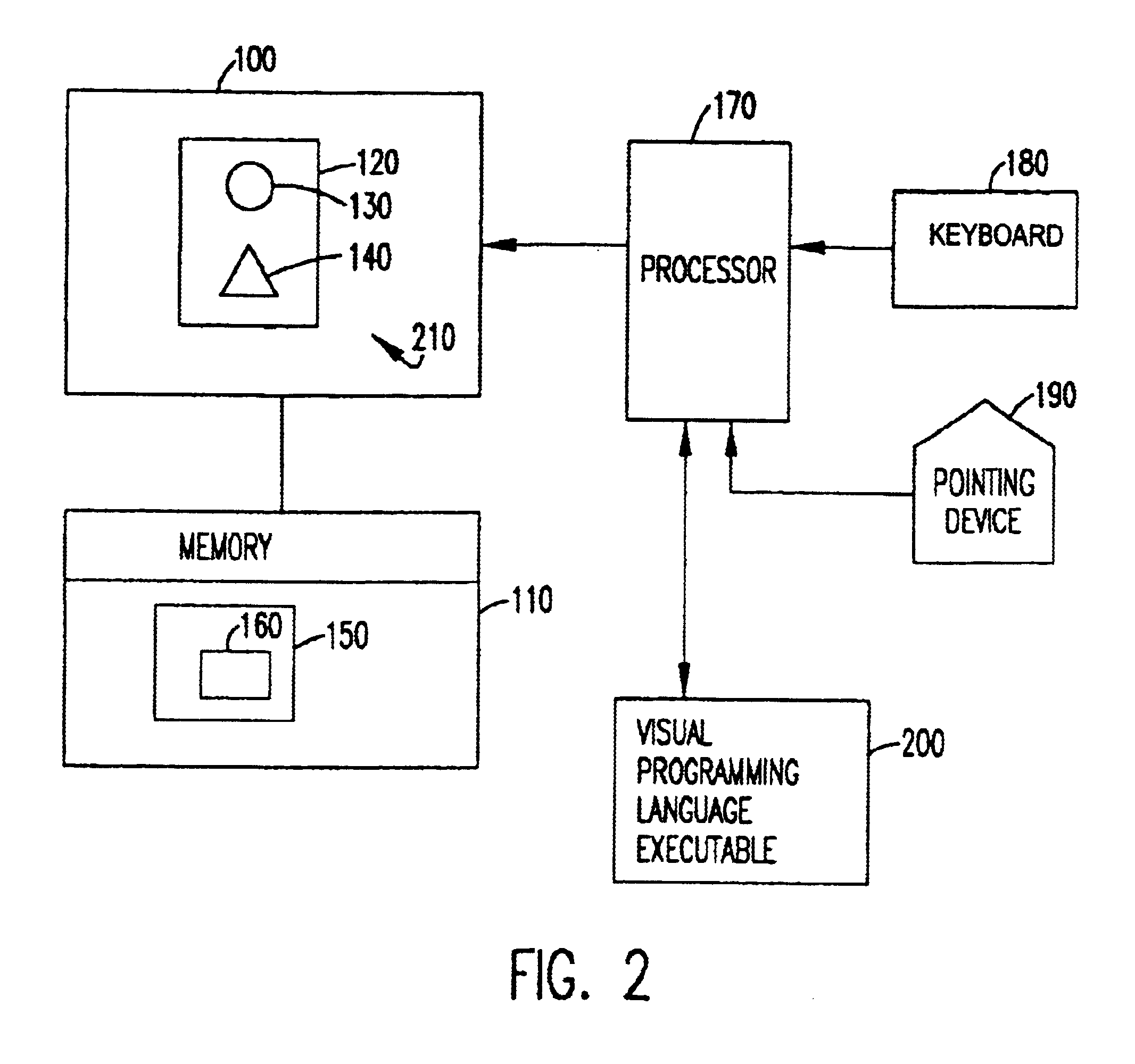

System and method for managing programming object visual representations participating in alternative execution paths

InactiveUS6683624B1Data processing applicationsCathode-ray tube indicatorsProgramming languageState space

A method and apparatus for depicting programming state of programming objects through a combination of associating semantic stat space with programming objects, updating semantic state through affiliated state updates with each programming action, and resolving the alternative programming states with a convergence operator defined on the semantic state space of the programming object type. The state reflection process is further defined in cases where the visual programming object participates in multiple execution paths, as would be the case in, for example, an IF statement wherein the variable is used on both the Left and Right sides. More particularly, this technique resolves these differing states back into a single state representation for the programming object.

Owner:IBM CORP

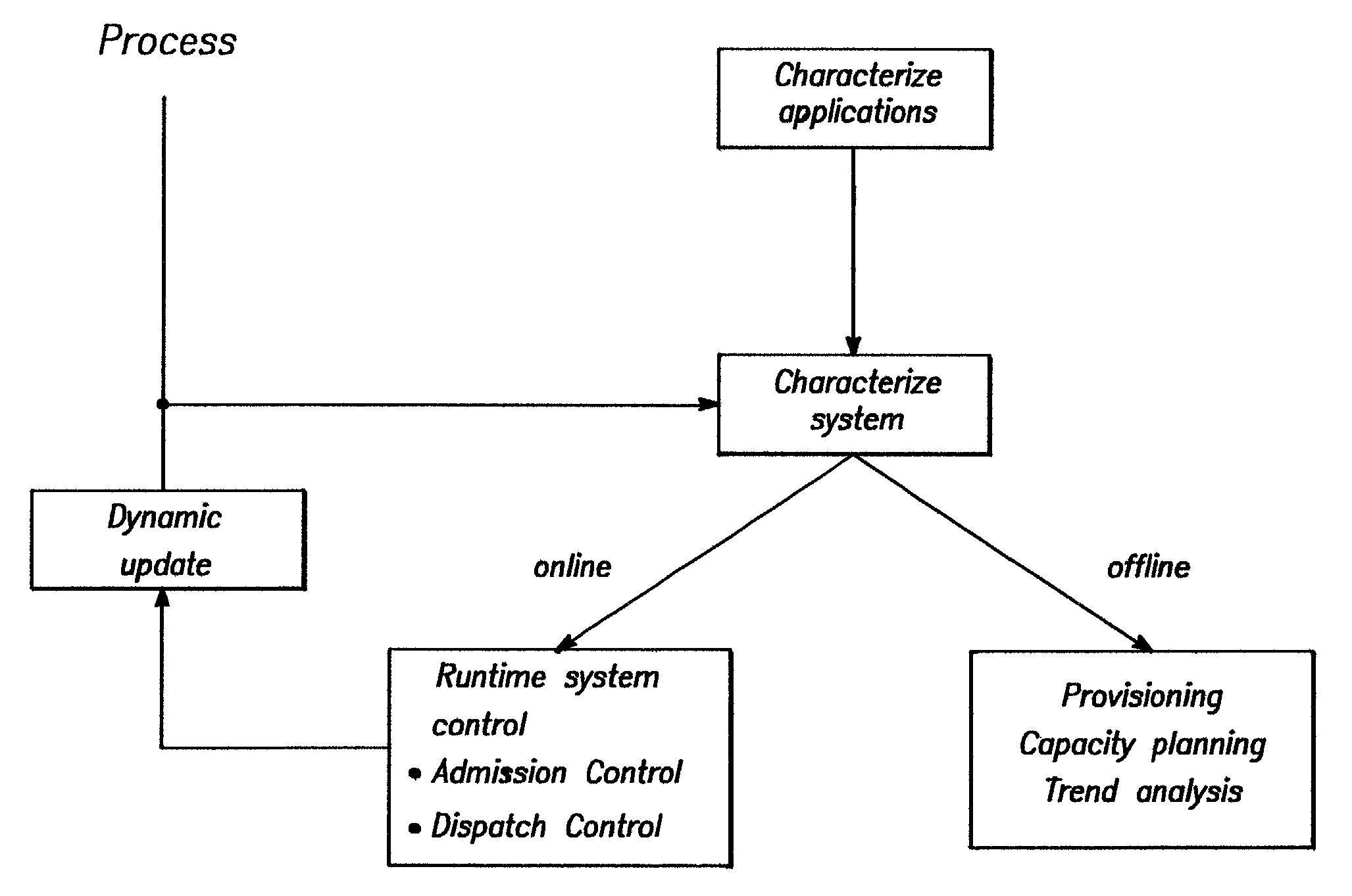

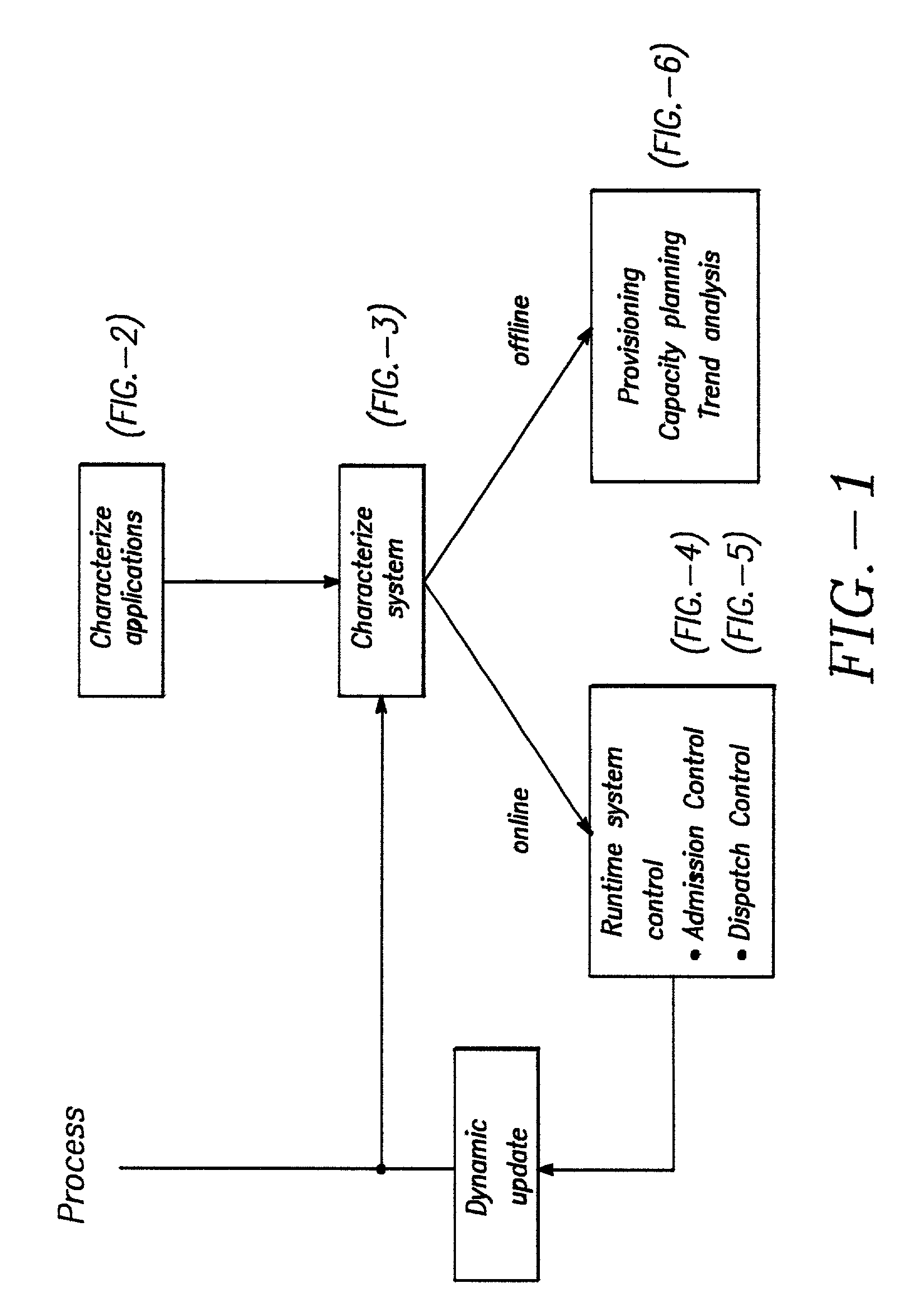

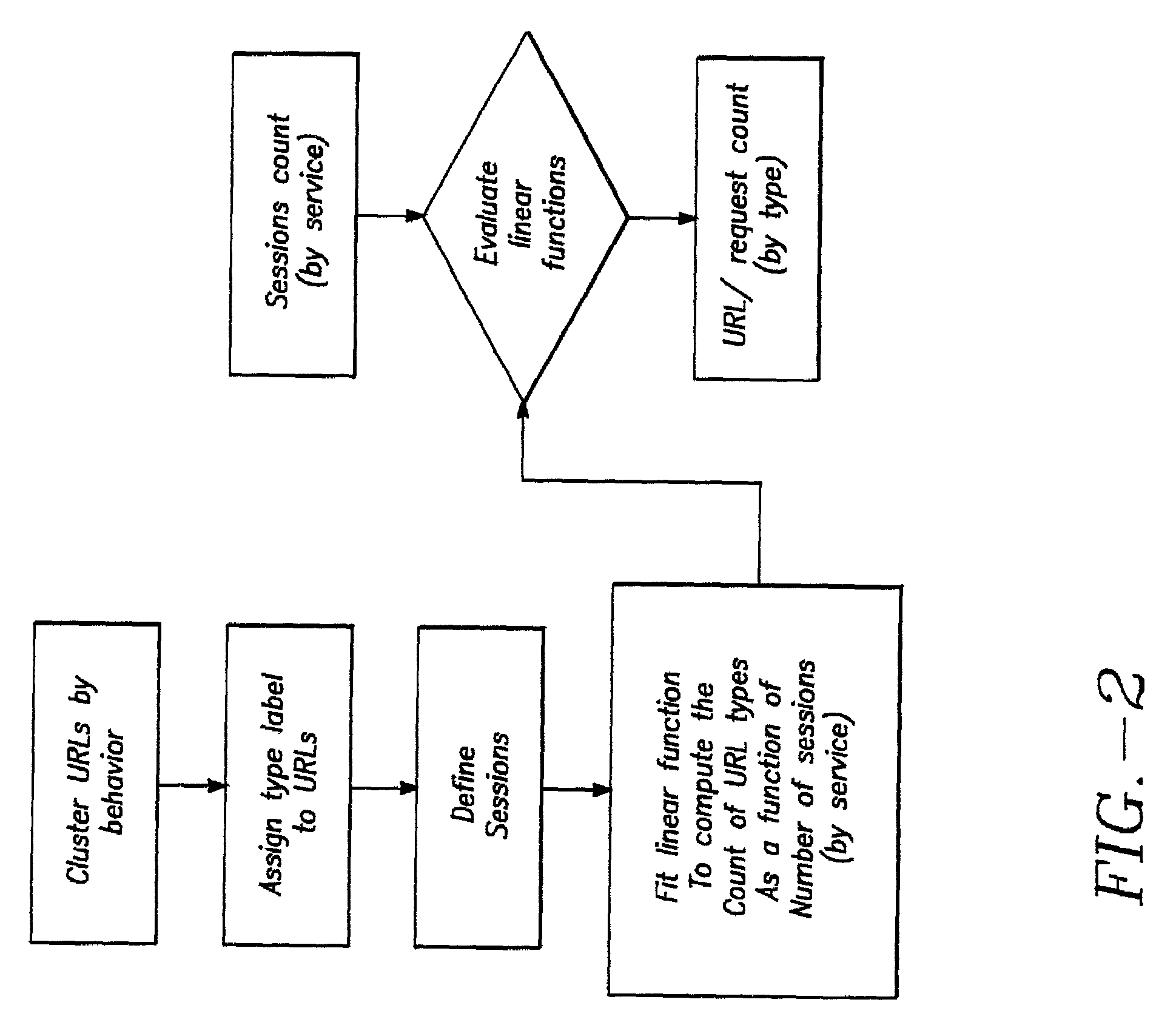

System and method for modeling information system capacity and accepting sessions in an information system

InactiveUS7113986B2Improved ability to alleviate quality of service problemEnergy efficient ICTResource allocationCurrent loadSystem capacity

A method for accepting a session in an information system server includes generating a representation of the session. The representation includes a first plurality of parameters that define a proposed additional load of the session on the information system server. A determination is made of a current state representation of the information system server. The current state representation is defined by a second plurality of parameters. The current state representation defines a current load on the information system server at a time instant. A determination is made of a headroom representation for the current state of the information system. The headroom representation is defined by a distance between a model surface.

Owner:ENTRUST

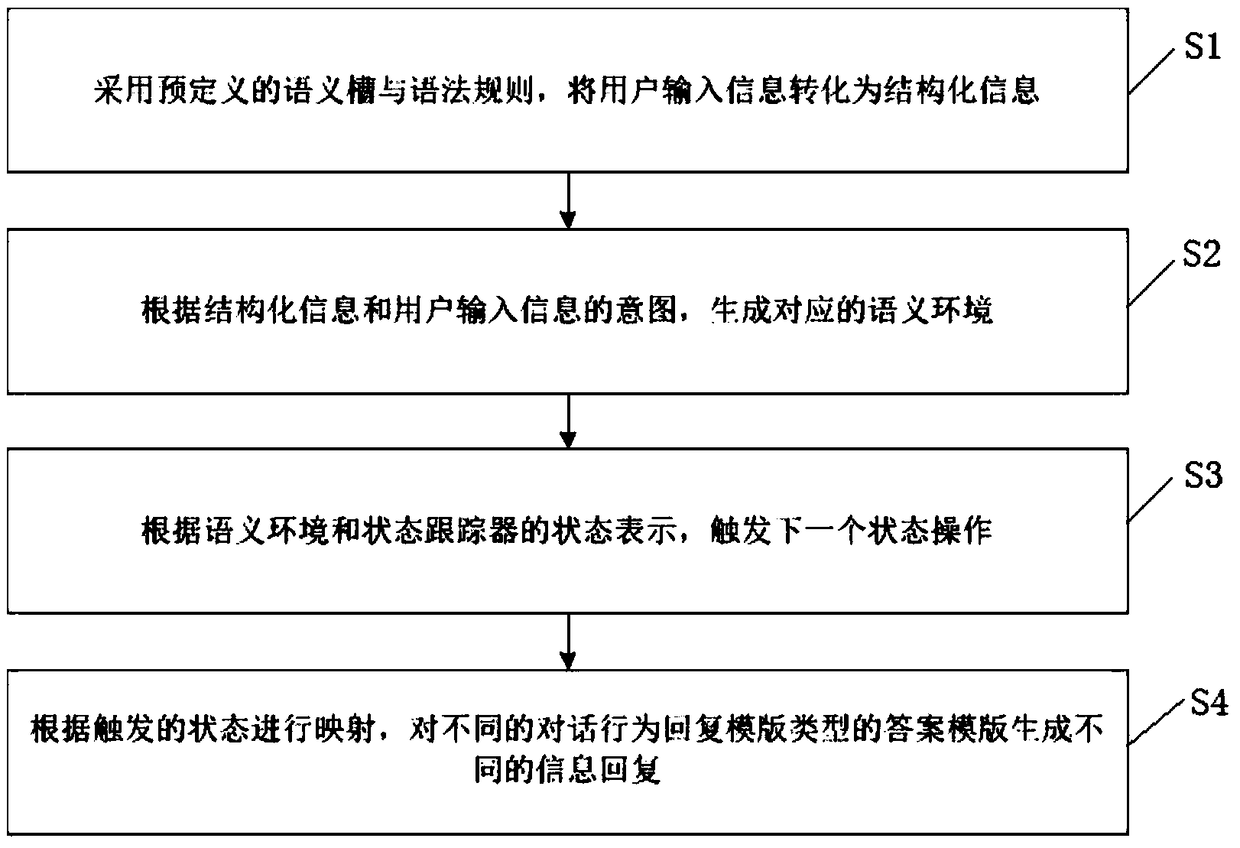

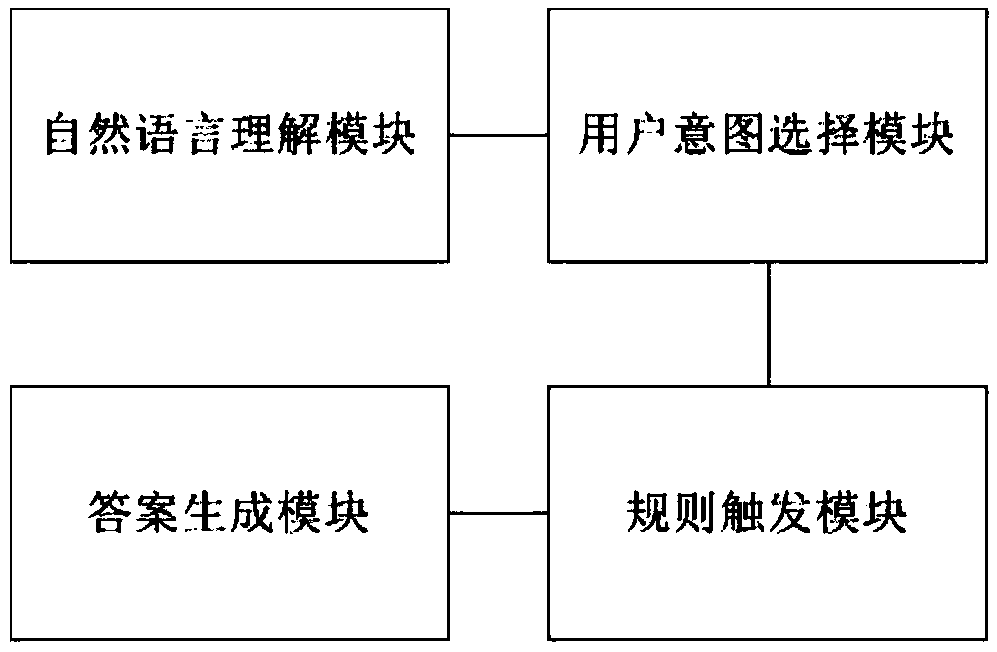

A method and system for strategy rule dialogue advance and intention discrimination

InactiveCN109241250AEffective assistanceText database queryingSpecial data processing applicationsDialogue actsUser input

The invention discloses a strategy rule dialogue advancing and intention judging method and system. The method comprises the following steps: S1, adopting predefined semantic slot and grammatical rules to convert user input information into structured information; S2, generating a corresponding semantic environment according to the intention of the structured information and the user input information; S3, triggering the next state operation according to the semantic environment and the state representation of the state tracker; S4, mapping according to the triggered state operation to generate different information replies to different conversation behavior replies templates. The invention can predefine semantic slot, for different conversations, retrieve Background Database, the system generates the semantic environment, triggers the operation according to the corresponding rules, pushes forward the multi-round dialogues with the user, judges the user's intention from the dialogues,and continuously decides the next optimal action according to the current state during the dialogues, so as to assist the user to complete the task of obtaining information or services most effectively.

Owner:南京瓦尔基里网络科技有限公司

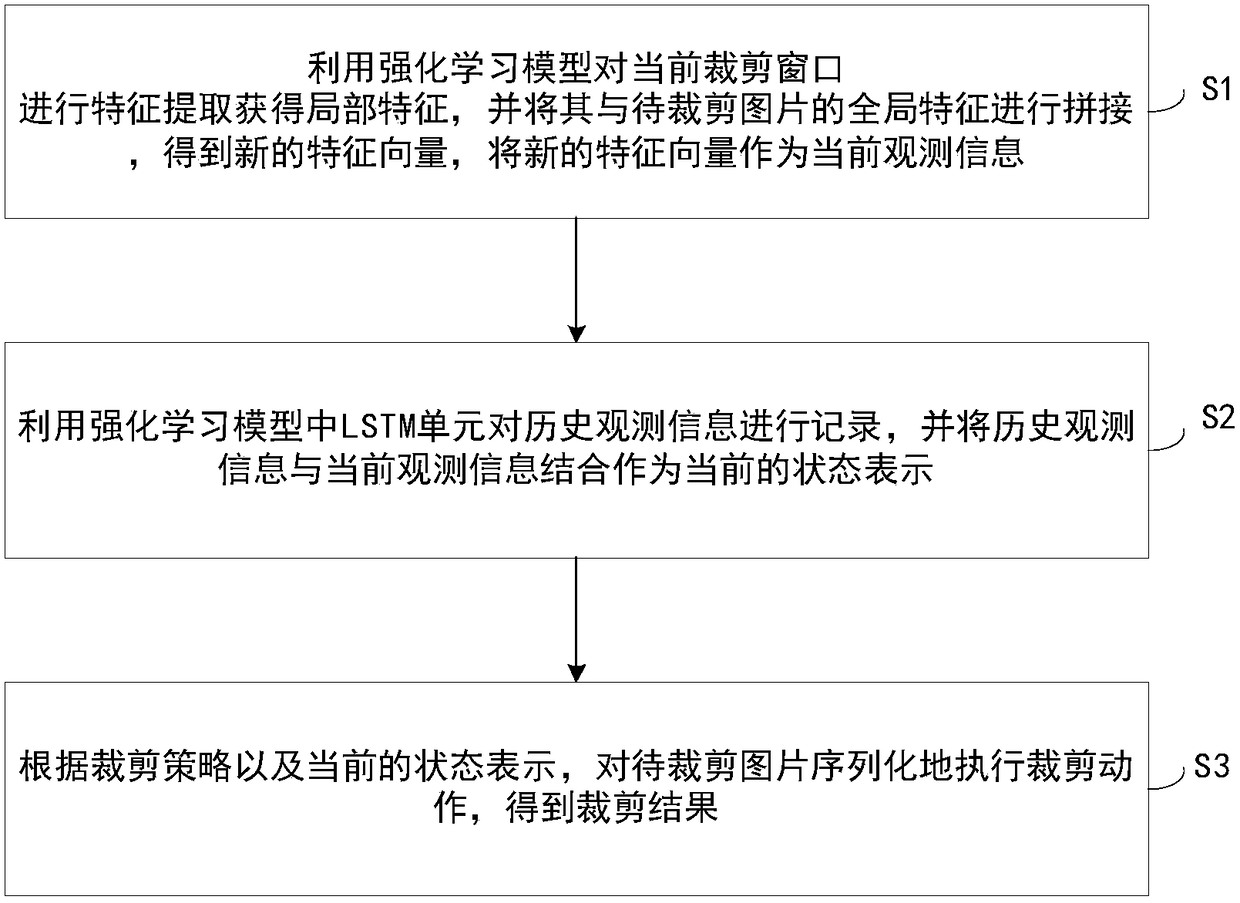

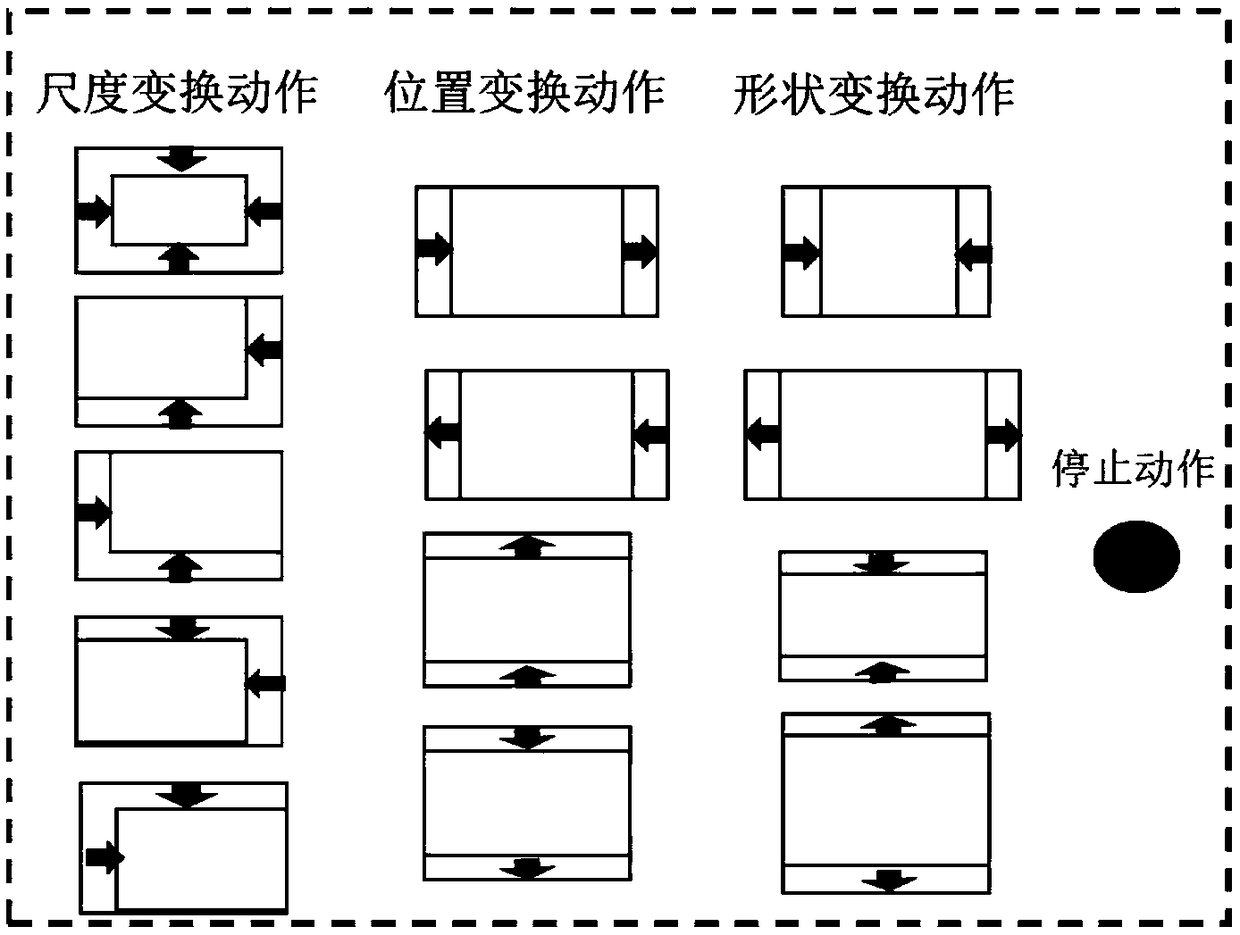

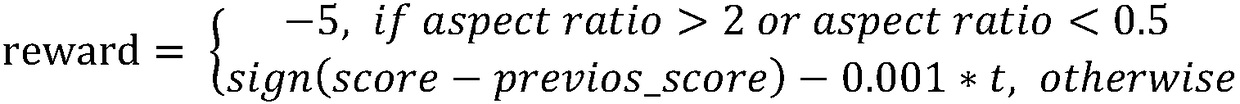

Reinforcement learning based automatic picture cutting method and device

ActiveCN108154464AReduce the amount of calculationReduce computing timeImage enhancementImage analysisFeature vectorImaging processing

The invention provides a reinforcement learning based automatic picture cutting method and device, relates to the field of image processing, and aims at obtaining an accurate picture cutting result rapidly. The method comprises the steps that a reinforcement learning model is used to carry out feature extraction on a present cutting window to obtain a local feature, the local feature is spliced toa global feature of the picture to be cut to obtain a new characteristic vector, and the new characteristic vector serves as present observation information; historical observation information obtained via the reinforcement learning model and the present observation information are combined and serve as present state representation; and according to a cutting strategy and the present state representation, a cutting motion is carried out on the picture to be cut sequentially, and a cutting result is obtained. The reinforcement learning model is a model which is established on the basis of a convolutional neural network. The method and device can be used to obtain the accurate picture cutting result rapidly.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

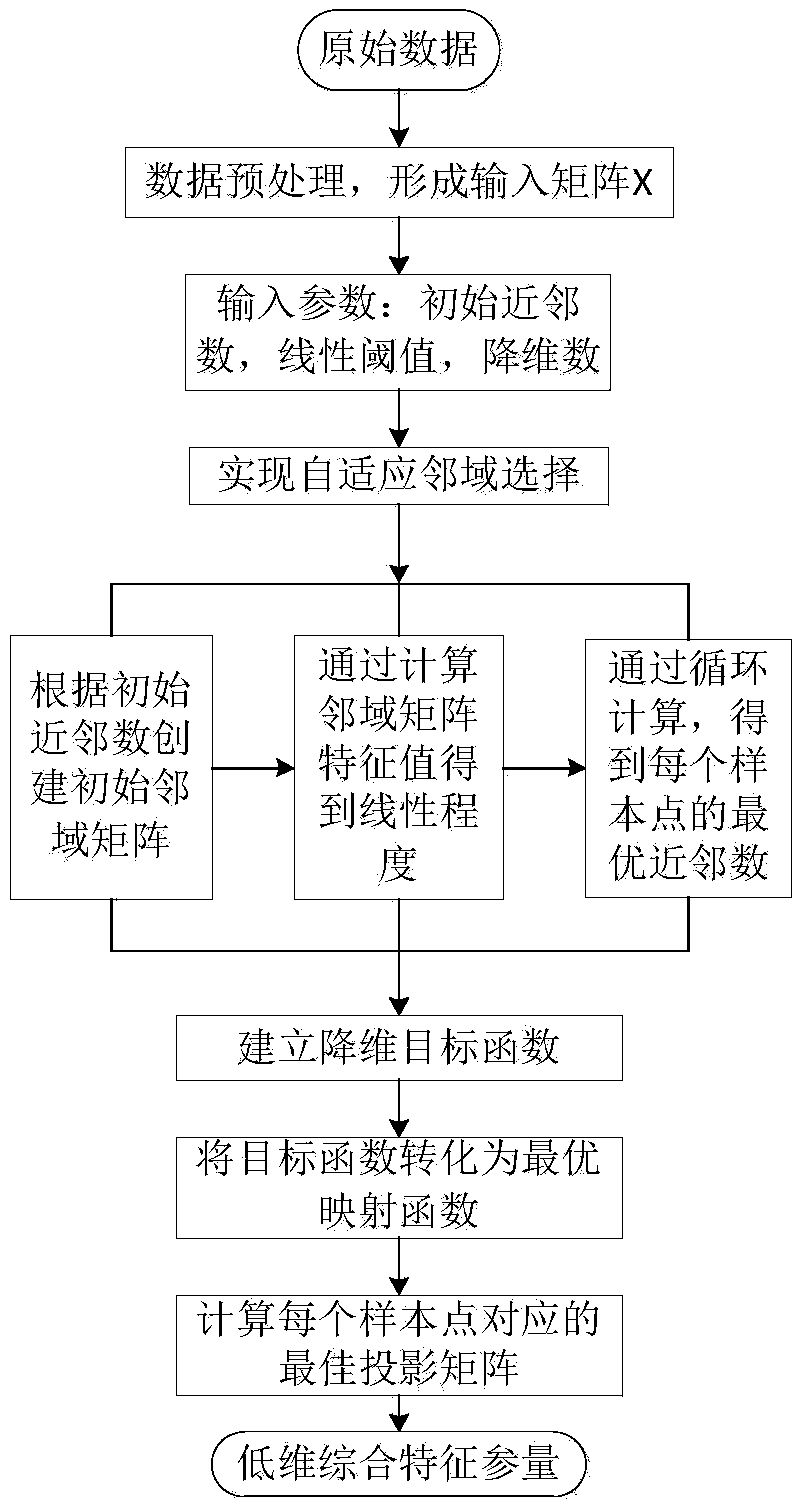

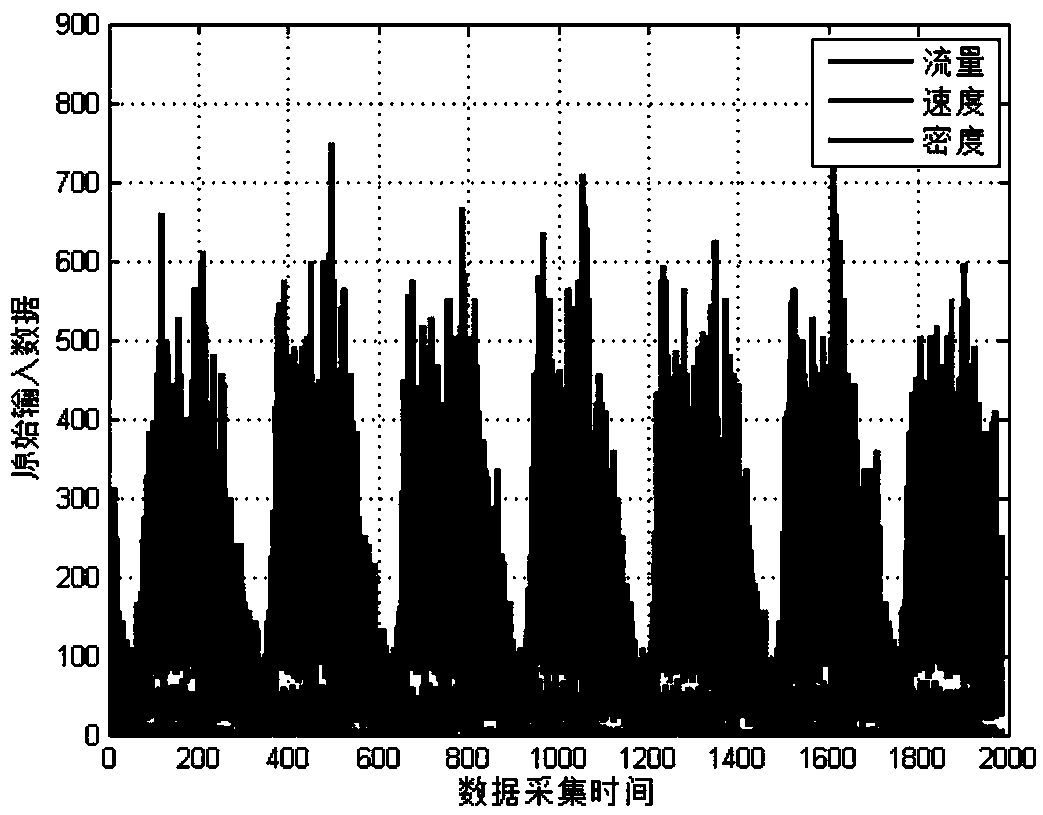

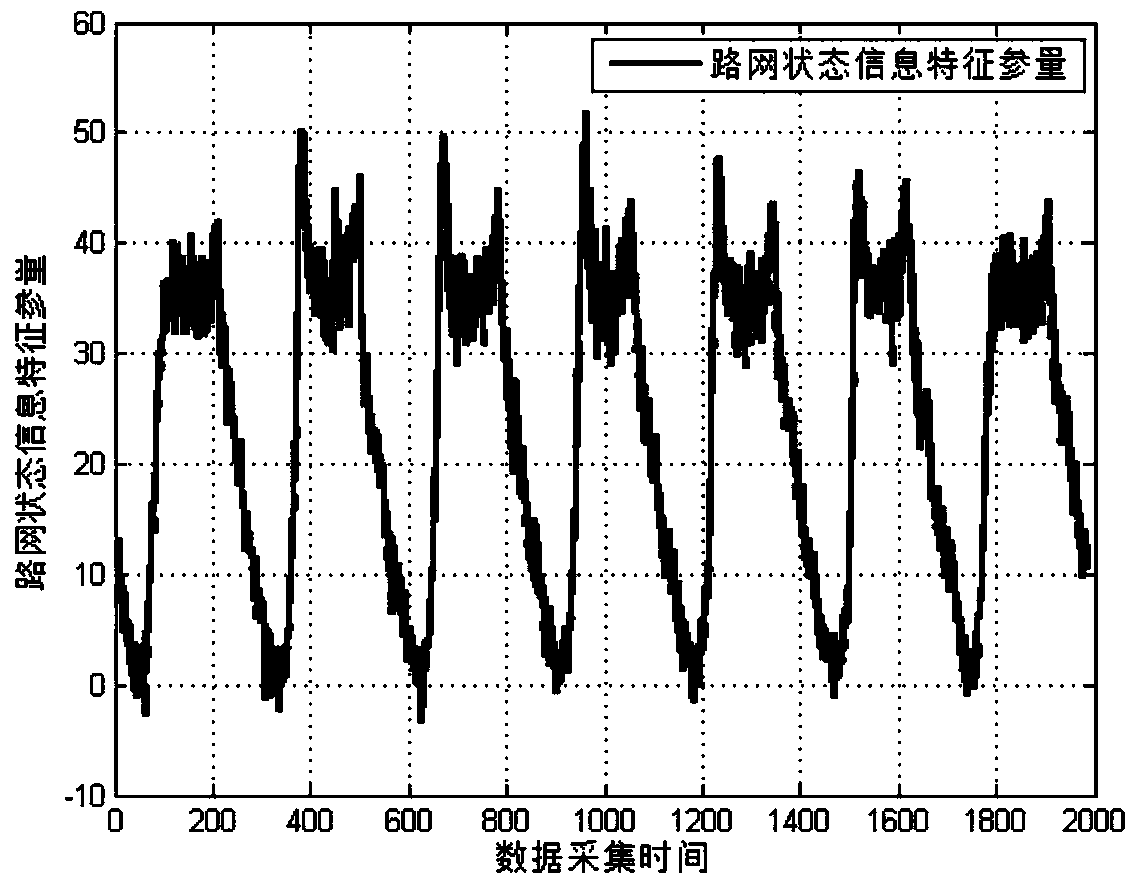

Urban region road network running state characteristic information extraction method

The invention discloses an urban region road network running state characteristic information extraction method. The method comprises steps that, step 1, the road network data is acquired; step 2, a road network data input matrix is constructed; step 3, adaptive neighborhood selection is carried out; step 4, characteristic information extraction is carried out; and step 5, visual representation of the road network running state characteristic information is carried out. The method is suitable for urban region road network characteristic information extraction and road network running state representation, on the basis of road network flow, speed and density data, an adaptive neighborhood selection manifold learning method is utilized to extract the road network running characteristic information, the road network running characteristic information has macroscopic property, accuracy, sensitivity and practicality, a macroscopic road network running state can be timely represented, and analysis and decision bases are provided for traffic managers.

Owner:BEIHANG UNIV

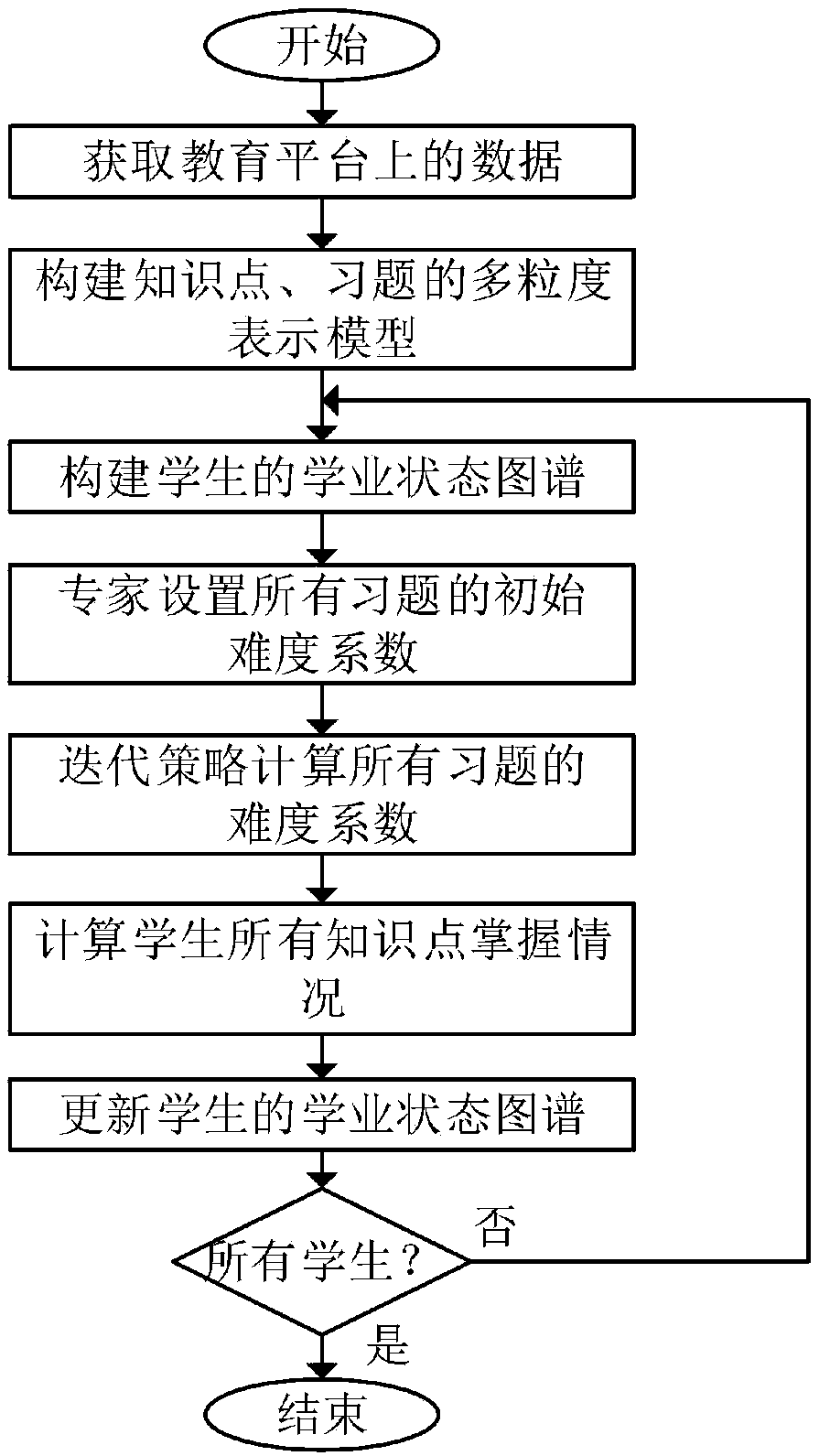

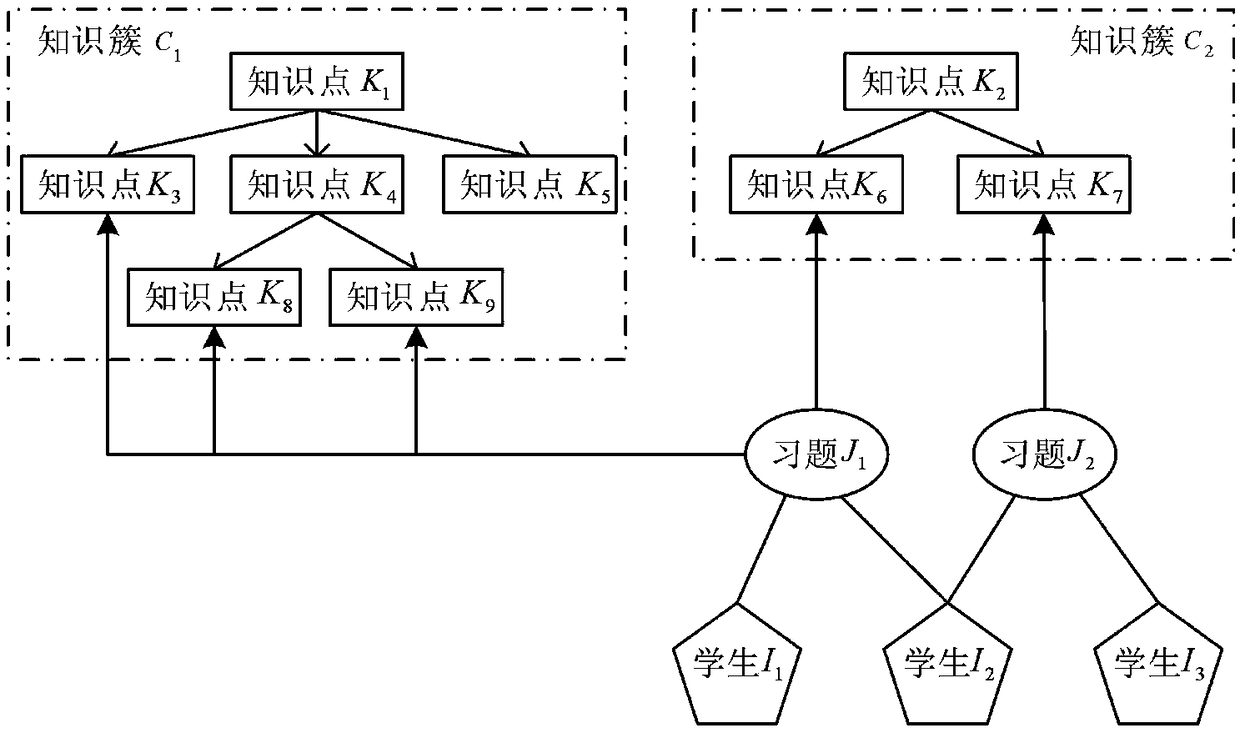

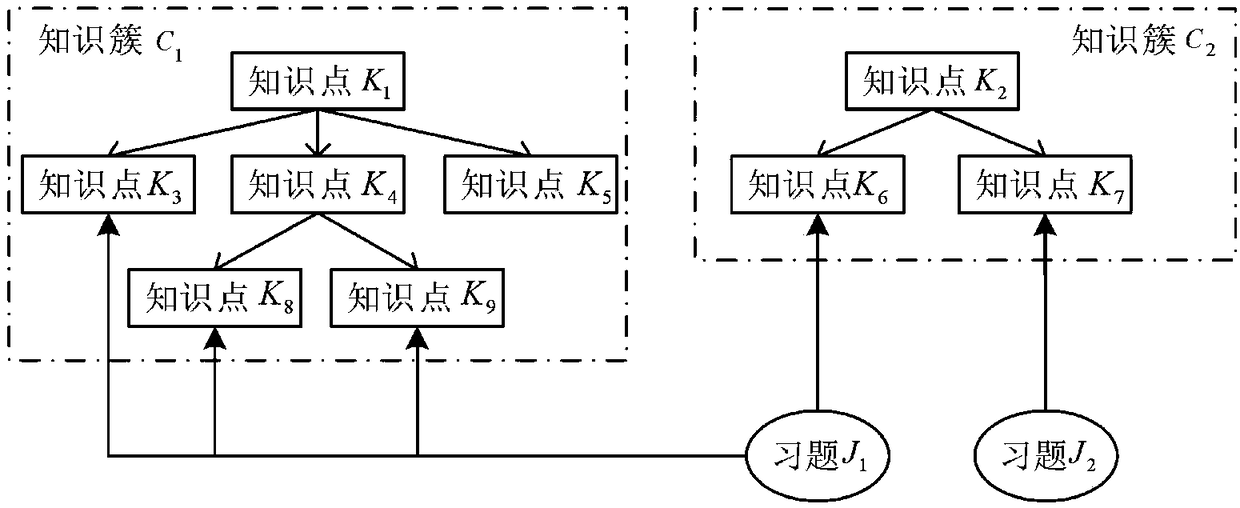

A cognitive diagnostic method for a cognitive process of a student

ActiveCN109191345ASolve the non-grained hierarchyAll-round analysisData processing applicationsOther databases indexingPhysical medicine and rehabilitationGranularity

The invention discloses a cognitive diagnostic method for a cognitive process of a student, comprising the following steps: constructing a multi-granularity representation model of knowledge points and exercises, constructing a learning state representation model of a student node, and analyzing the cognitive diagnosis of the student node. The invention can use the method of knowledge map to express the academic state of the students in multi-granularity, so as to analyze the mastery degree of the corresponding knowledge points of the students according to the answers of the students accordingto the different cognitive processes of the students.

Owner:HEFEI UNIV OF TECH

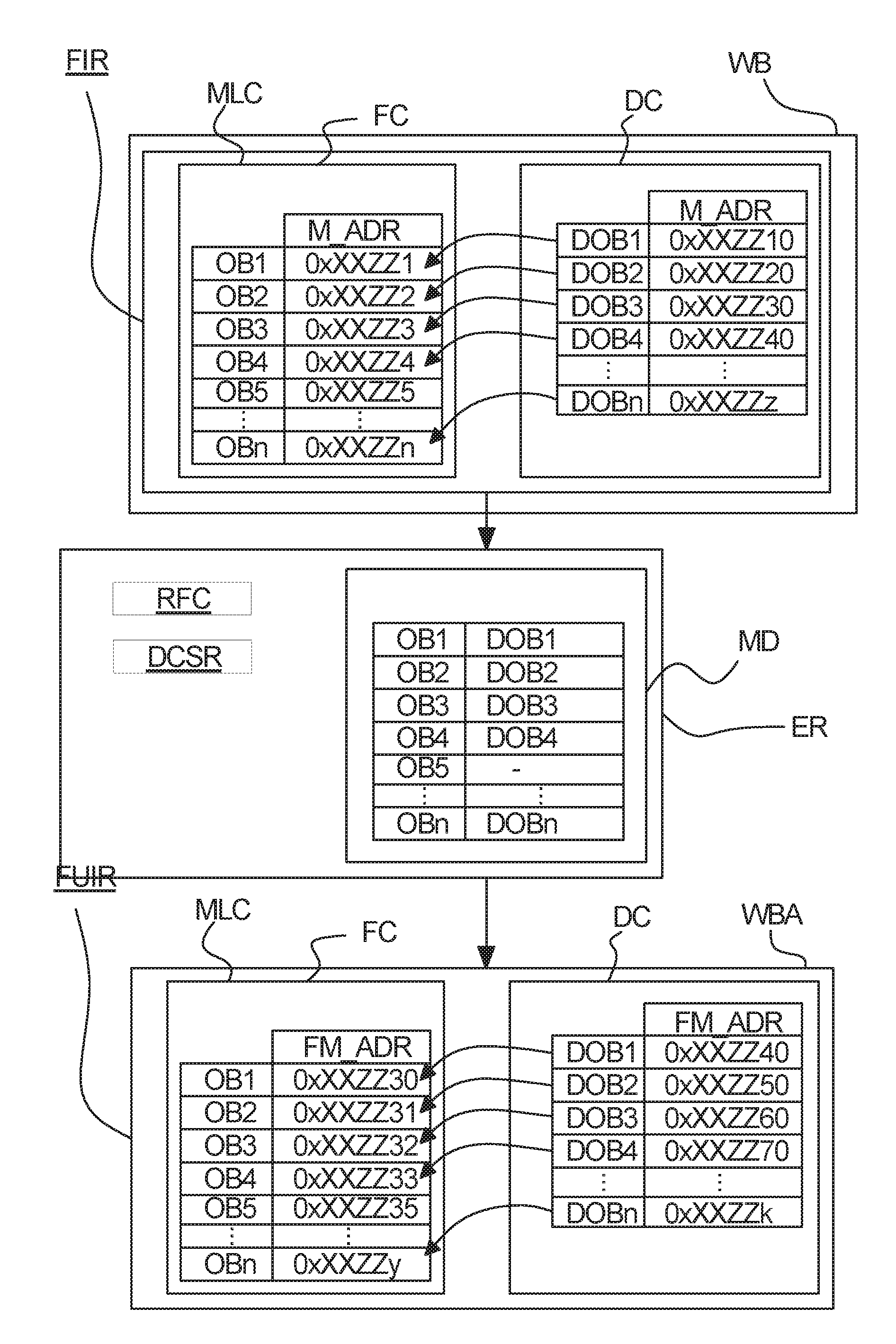

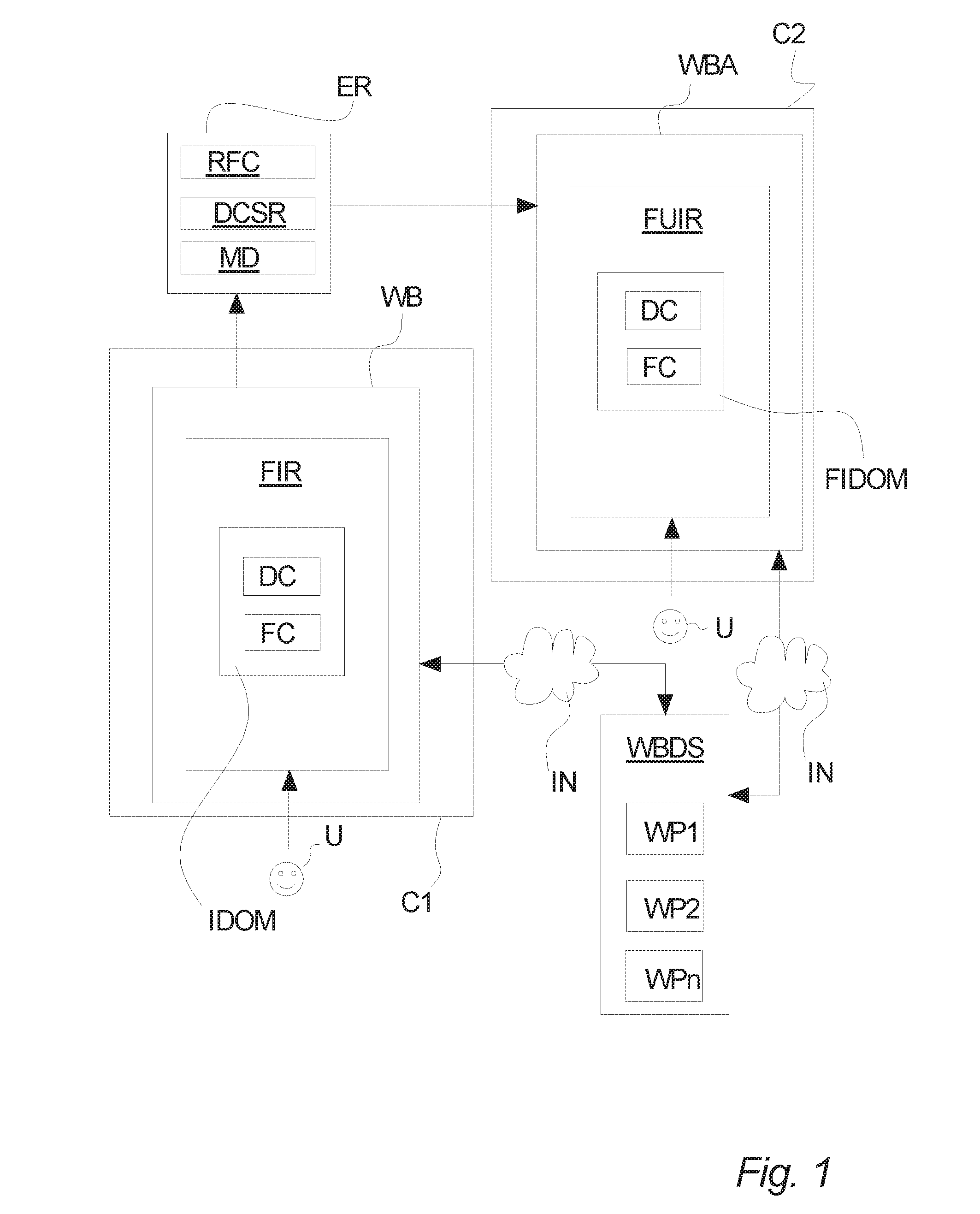

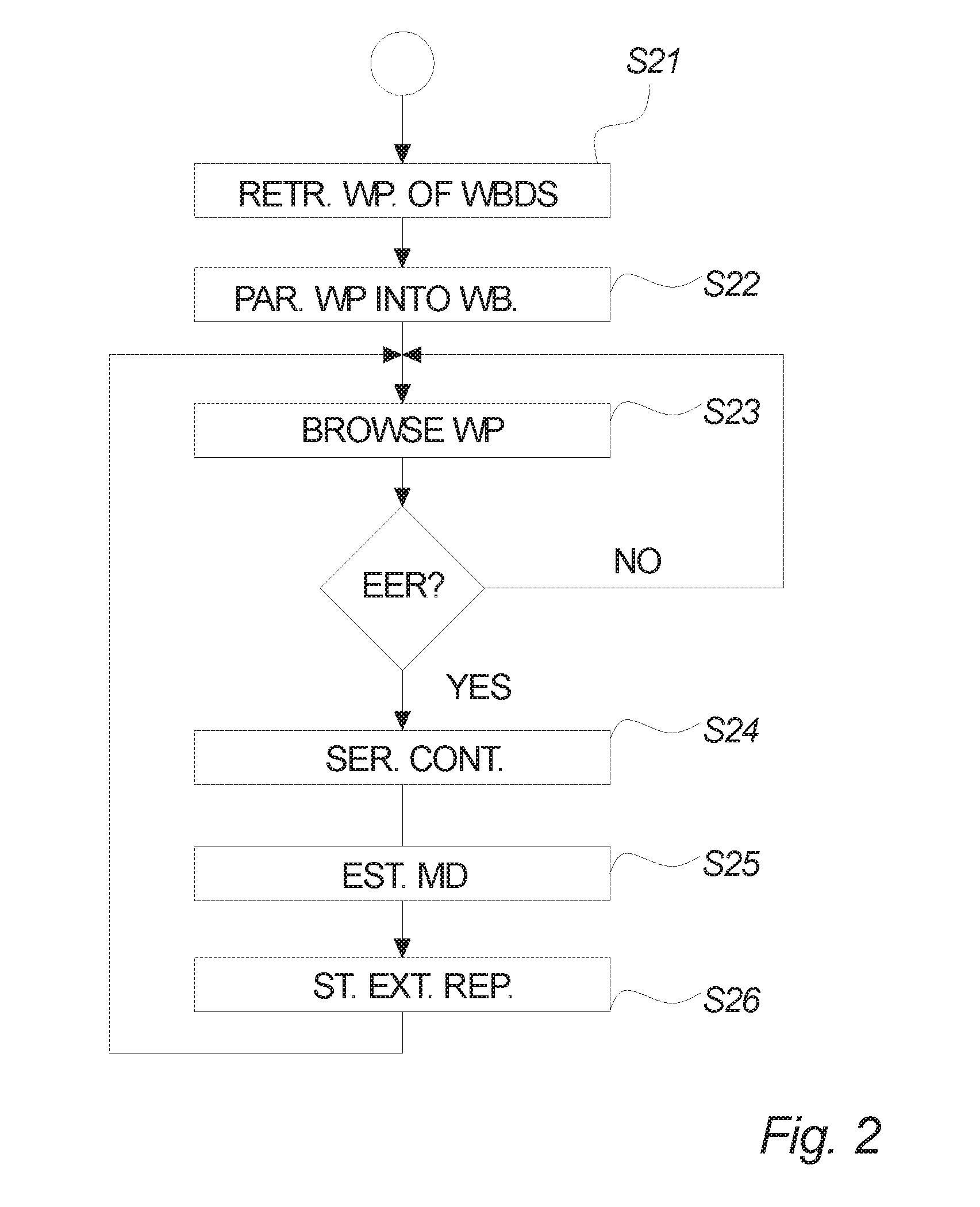

Establishment of state representation of a web page represented in a web browser

InactiveUS20170004221A1Website content managementSpecial data processing applicationsWeb browserData source

The presently disclosed inventive concepts relate to establishing a state representation of a web page represented in a web browser. This concept includes processing a web page retrieved from a web based data source; establishing a resulting first internal browser state representation of the web page; establishing an external representation representing a state of the first internal representation; establishing a representation of a first content of the first internal browser state representation; establishing a dynamic content state representation which represents the state of the dynamic content of the first internal browser state representation; establishing mapping data comprising relationships between the dynamic content and the first content; and making the external representation available to a web browser application so as to establish a further internal representation of the web page in the web browser application at a state corresponding to the state of the first internal browser state representation.

Owner:KAPOW TECH

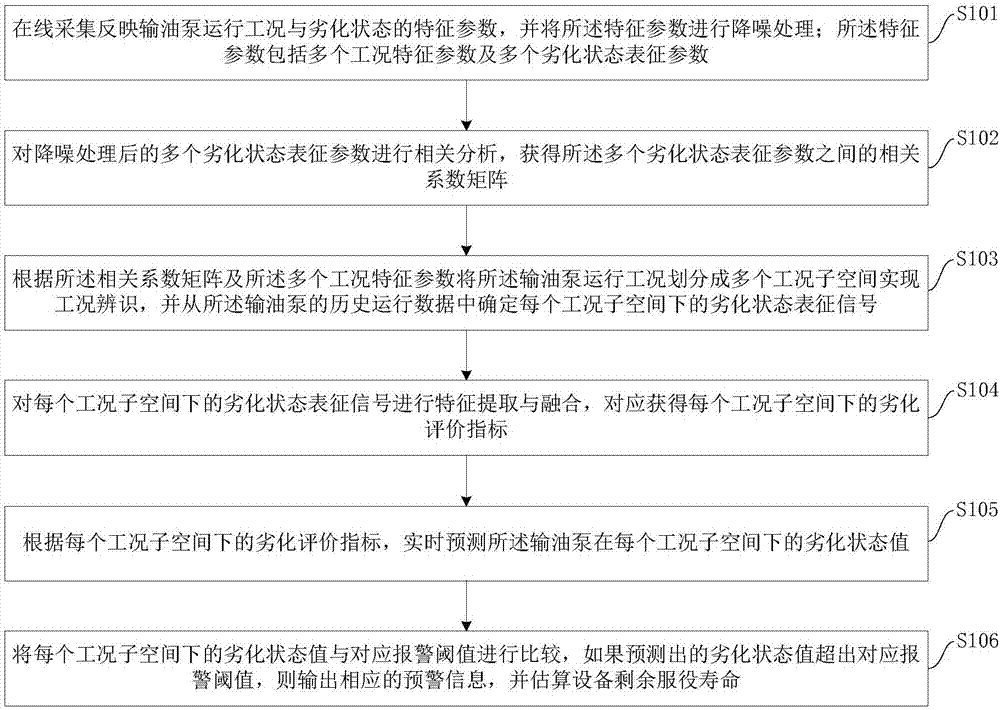

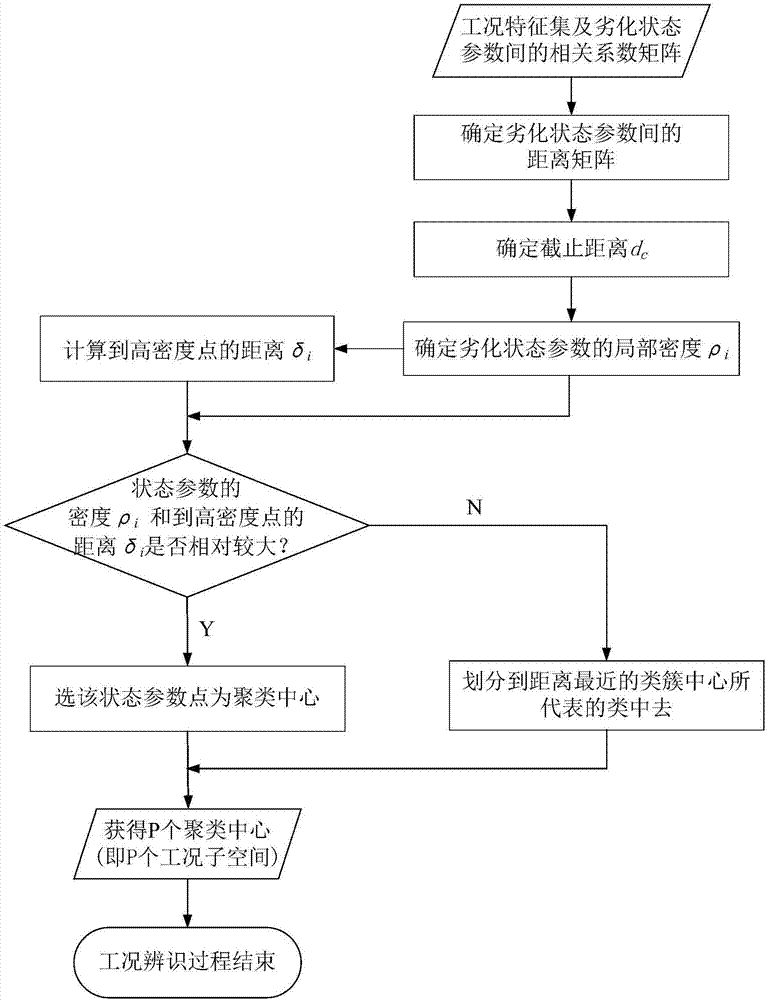

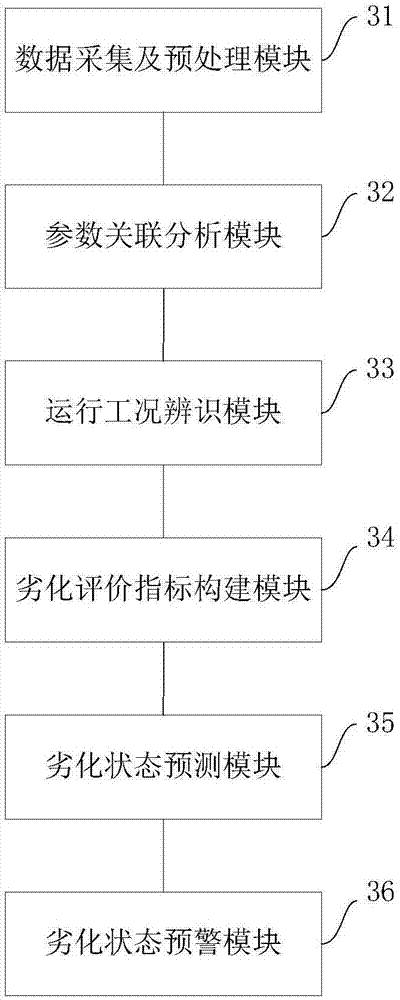

Adaptive state early warning system and method of working conditions of oil transmission pump

The invention provides an adaptive state early warning system and method of working conditions of an oil transmission pump. The method comprises steps of carrying out online acquisition on characteristic parameters of operation working stations and deterioration states of the oil transmission pump, wherein the characteristic parameters comprise working condition characteristic parameters and deterioration state representation parameters; carrying out related analysis on the deterioration state representation parameters to acquire related coefficients between the deterioration state representation parameters; according to the related coefficients and the working condition characteristic parameters, dividing the working conditions of the oil transmission pump into multiple working condition sub-spaces, determining deterioration state representation signals of the working condition sub-spaces from history operation data of the oil transmission pump, and carrying out characteristic extraction and fusion on the deterioration state representation signals to acquire a deterioration evaluation index in each working condition sub-space; and according to the deterioration evaluation index in each working condition sub-space, predicating a deterioration state value in each working condition sub-space of the oil transmission pump in real time, comparing the deterioration state values with a corresponding alarming threshold and if the deterioration state values exceed the alarming threshold, outputting corresponding alarming information. According to the invention, deterioration states of the oil transmission pump can be precisely predicated under variable operation working conditions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

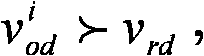

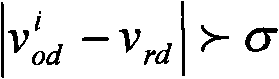

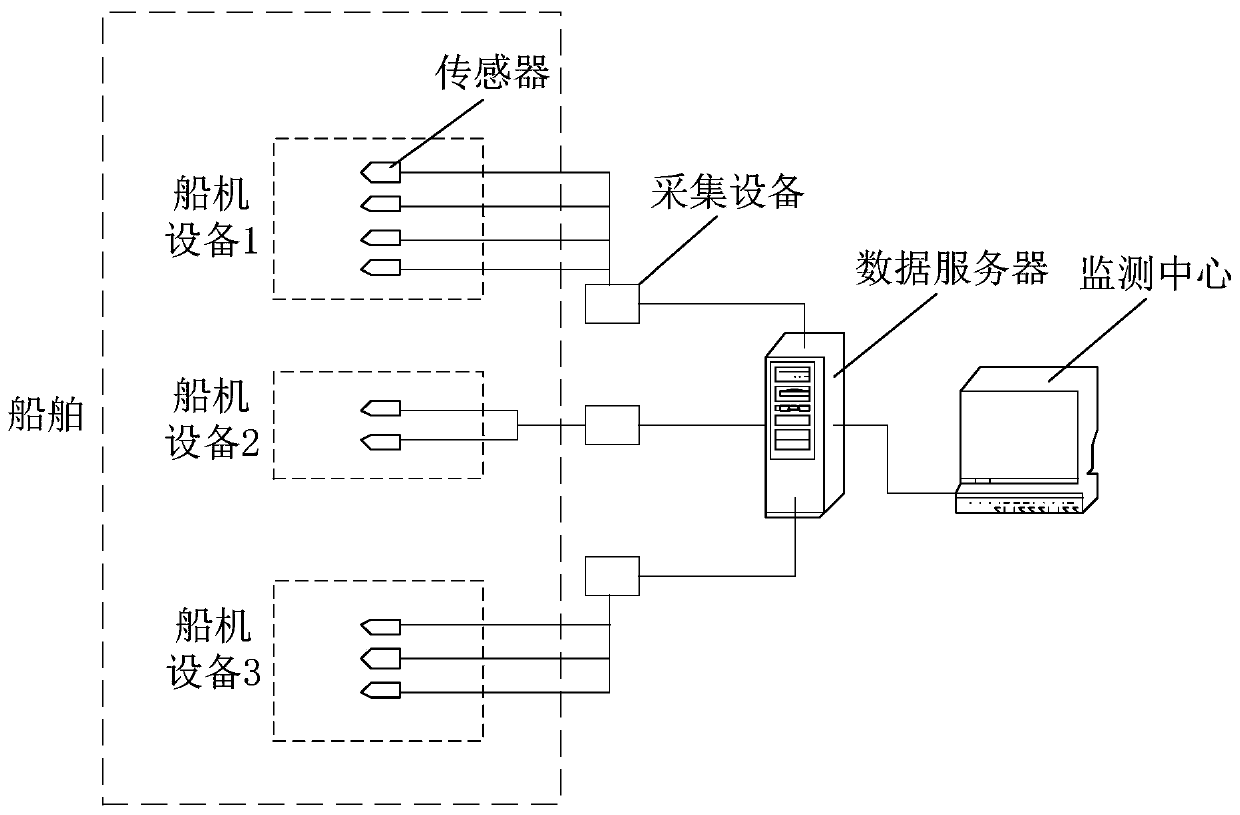

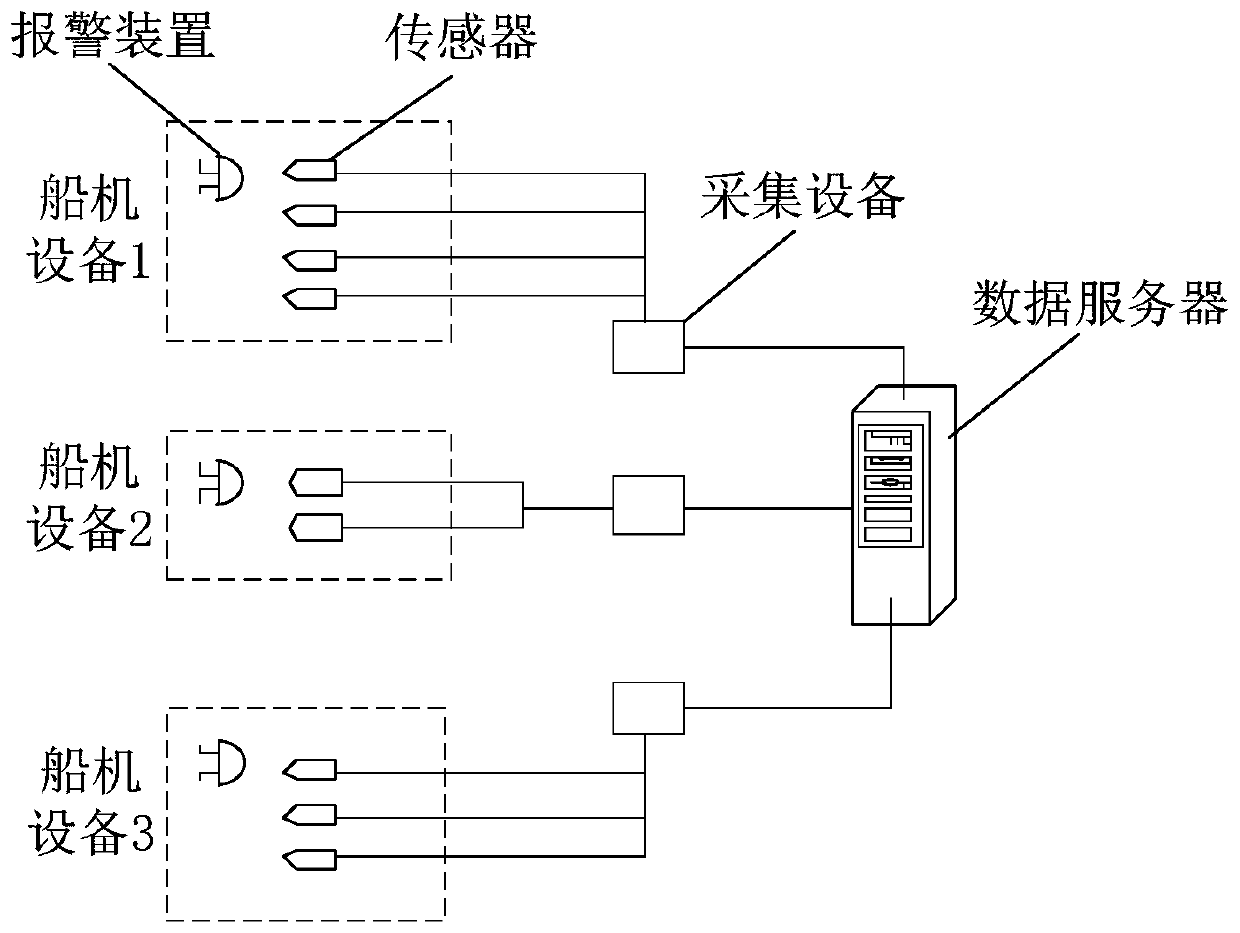

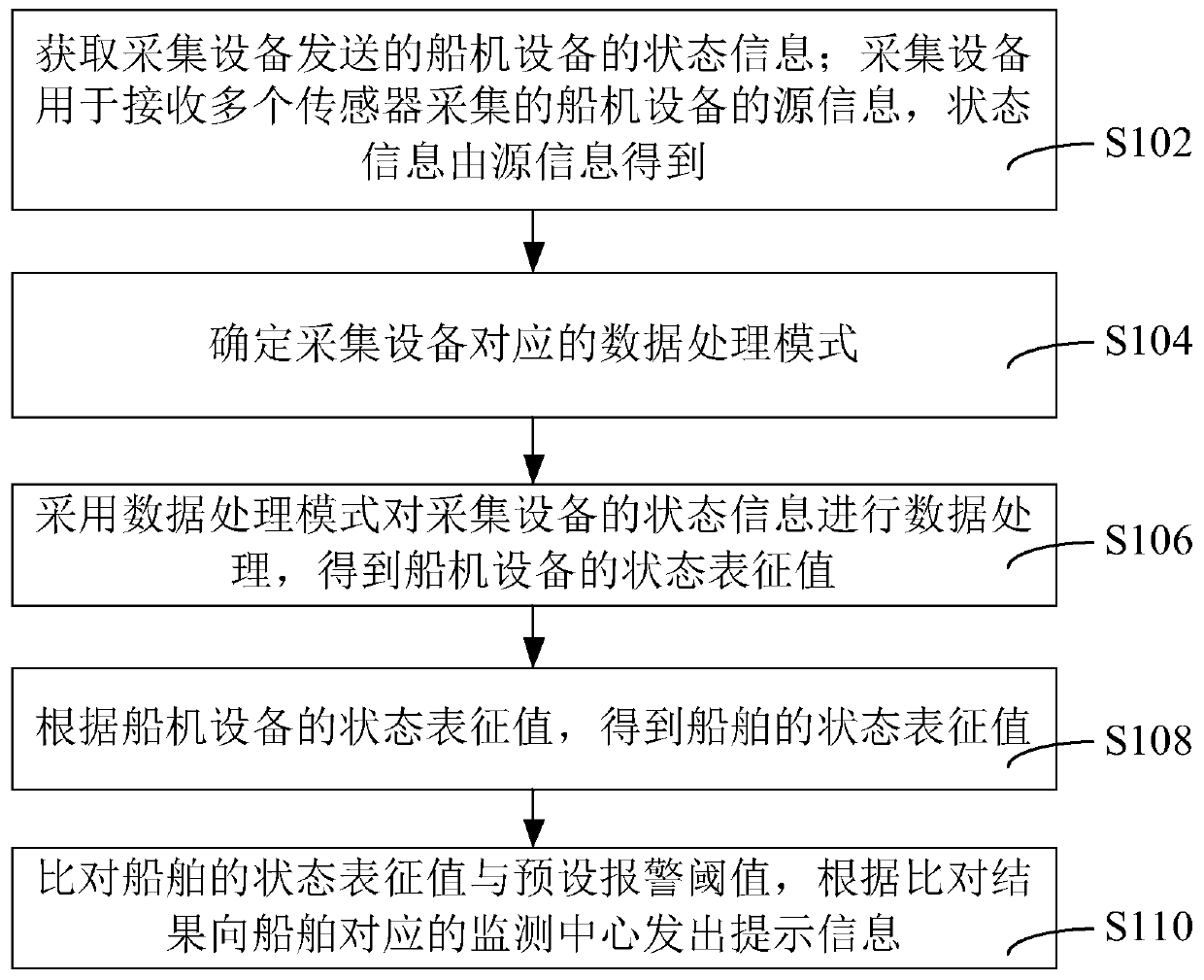

Ship monitoring method, device and system, and storage medium

ActiveCN110085006ARealize real-time monitoringEasy to maintain in timeVisible signalling systemsAlarmsState representationMonitoring methods

The invention relates to a ship monitoring method, device and system, and a storage medium. The method comprises the following steps: acquiring state information of ship-borne equipment sent by acquisition equipment, wherein the acquisition equipment is used for receiving source information of ship-borne equipment acquired by a plurality of sensors, and the state information is obtained from the source information; determining a data processing mode corresponding to the acquisition equipment; performing data processing on the state information of the acquisition equipment by adopting the dataprocessing mode to obtain a state representation value of the ship-borne equipment; obtaining a state representation value of the ship according to the state representation value of the ship-borne equipment; and comparing the state representation value of the ship with a preset alarm threshold value, and sending prompt information to a monitoring center corresponding to the ship according to a comparison result. By adopting the method, the influence of external environment and subjective factors can be avoided, and the monitoring result is accurate; A real-time monitoring of the working stateof a ship is realized, the timely maintenance of the ship is facilitated, and the efficiency is high.

Owner:CCCC GUANGZHOU DREDGING +1

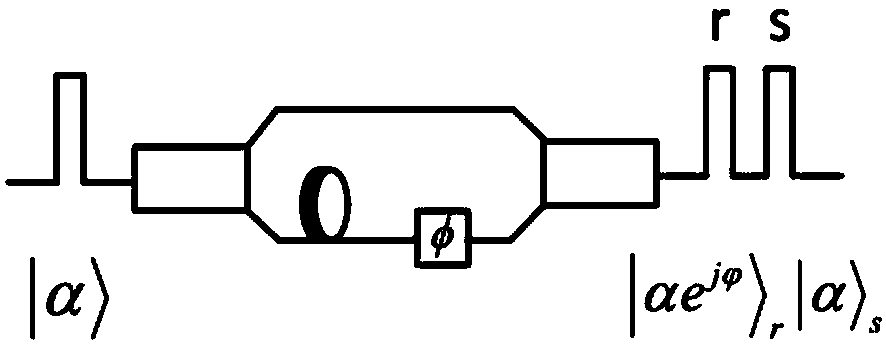

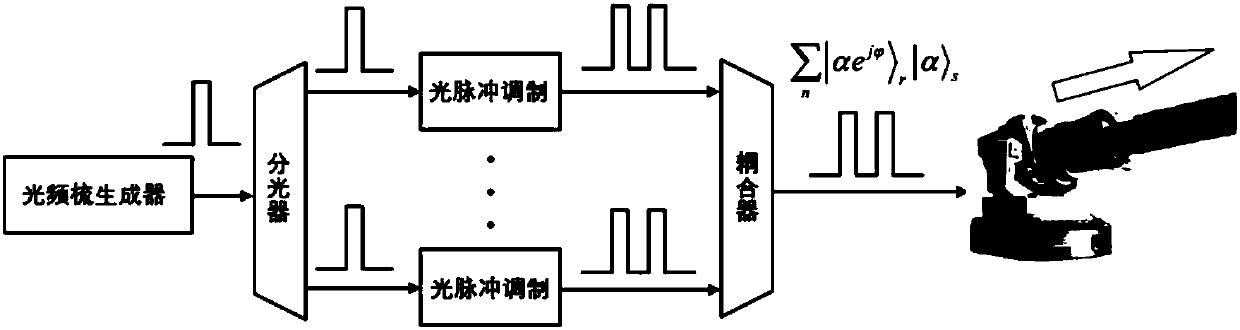

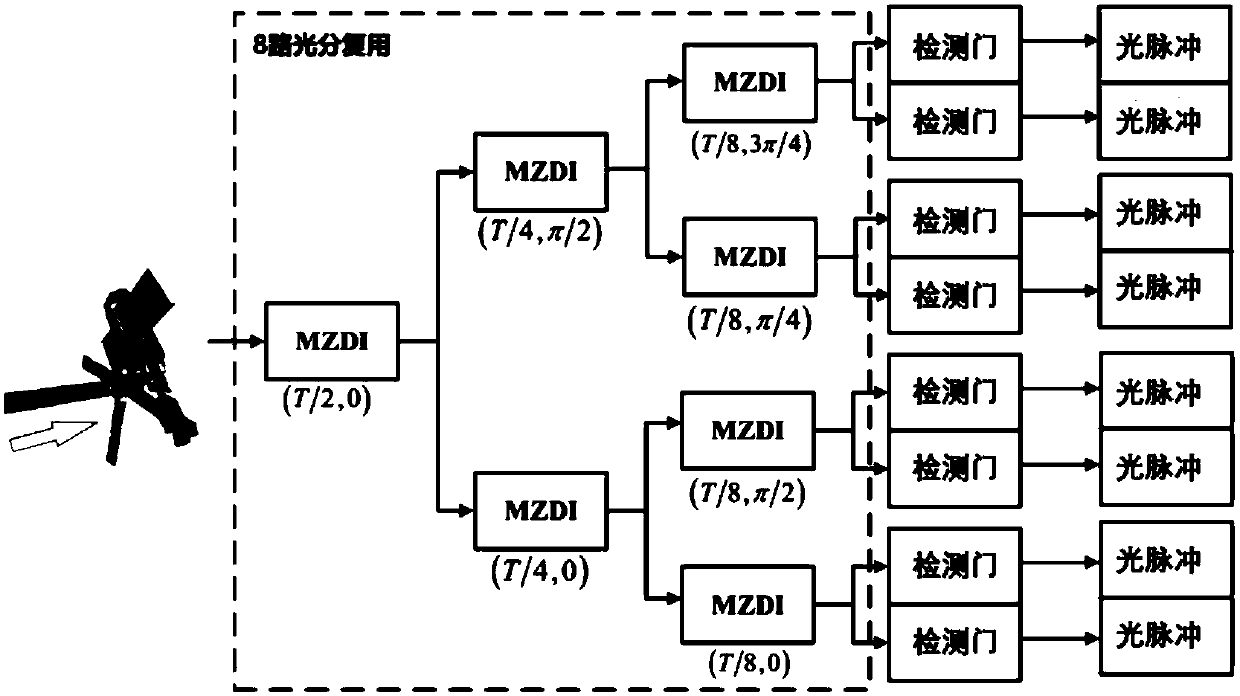

Optical quantum OFDM communication system and quantum information detection method thereof

InactiveCN108234028AImprove performanceReduce optical powerPhotonic quantum communicationMulti-frequency code systemsSystems designCommunications system

The invention discloses an optical quantum OFDM communication system and a quantum information detection method thereof. The invention introduces the orthogonal frequency division multiplexing technology to the quantum communication, and provides the quantum communication system based on an all-optical OFDM model; meanwhile, the invention presents that a transmitted quantum state symbol set is expanded under the optical quantum digital state representation, and the minimum square root measurement (SRM) method with better performance in the positive operator valued measure (POVM) is used for algorithm measurement. The invention gives the system design and the basic principle explanation and performance simulation method and result, and performs simulation on the quantum state detection performance and part factors affecting the system performance separately. Results show that for the optical quantum OFDM system, the bit error rate performance of the quantum detection method based on theminimum square root is better than that of the classical detection method.

Owner:FUDAN UNIV

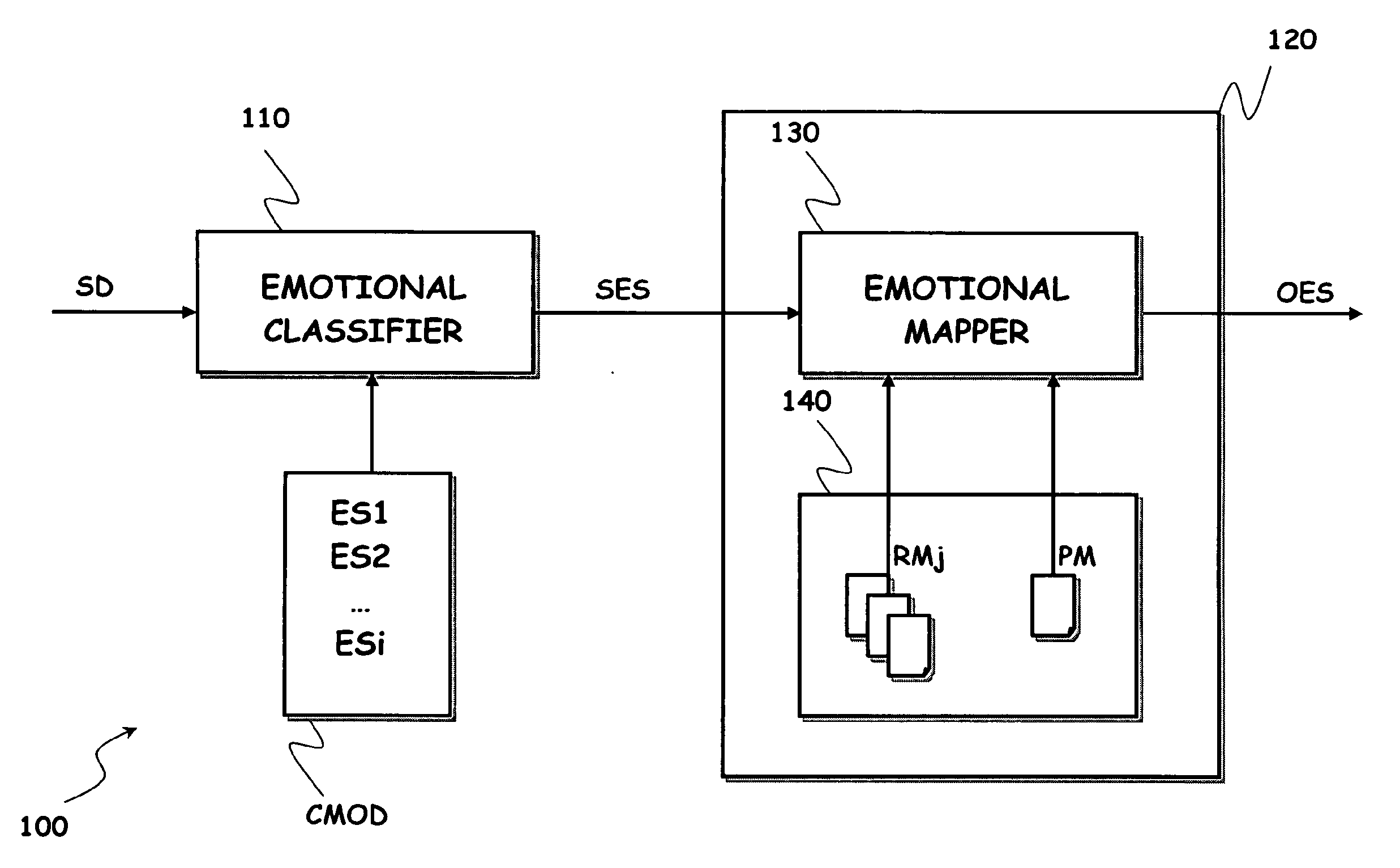

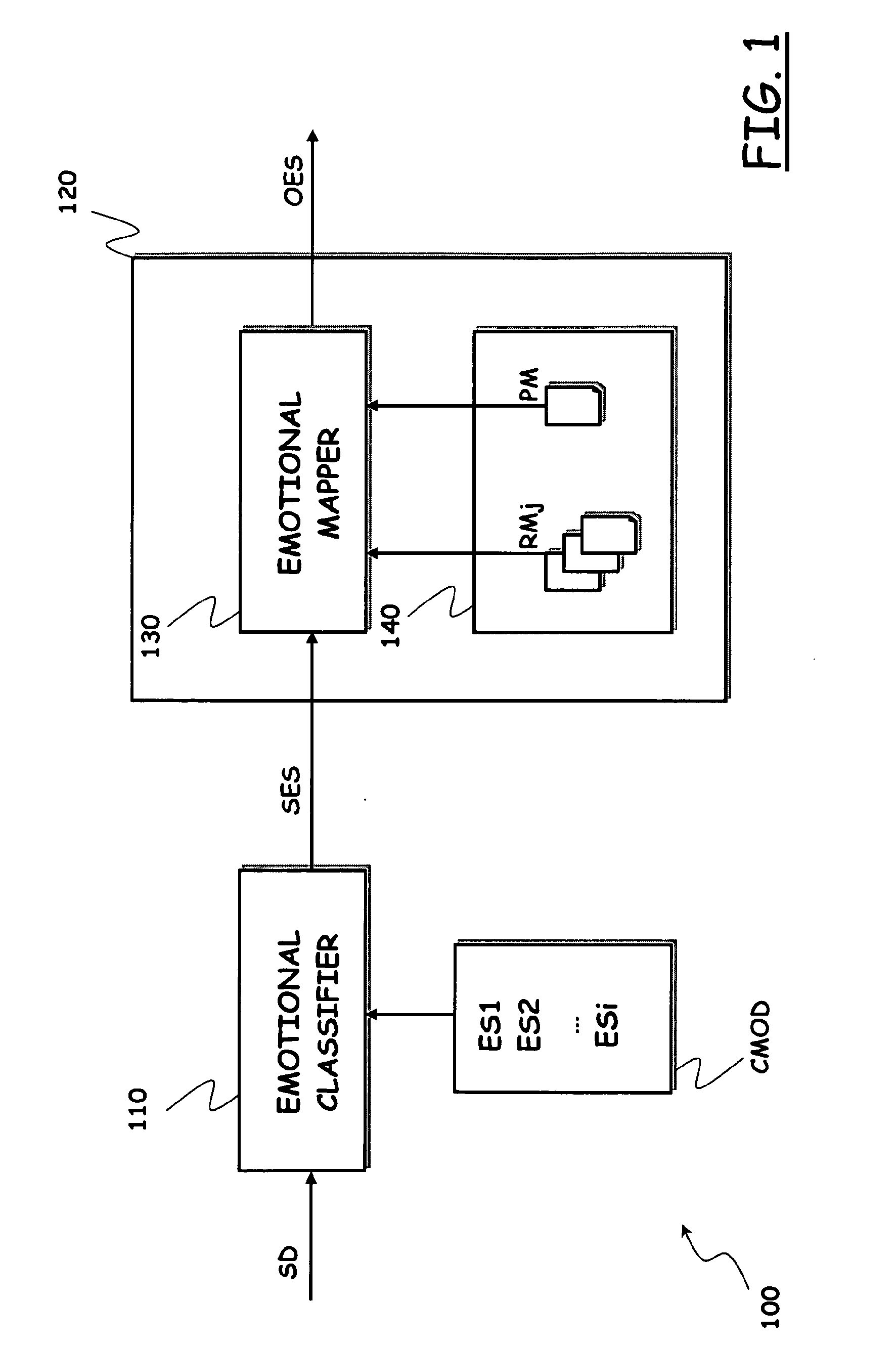

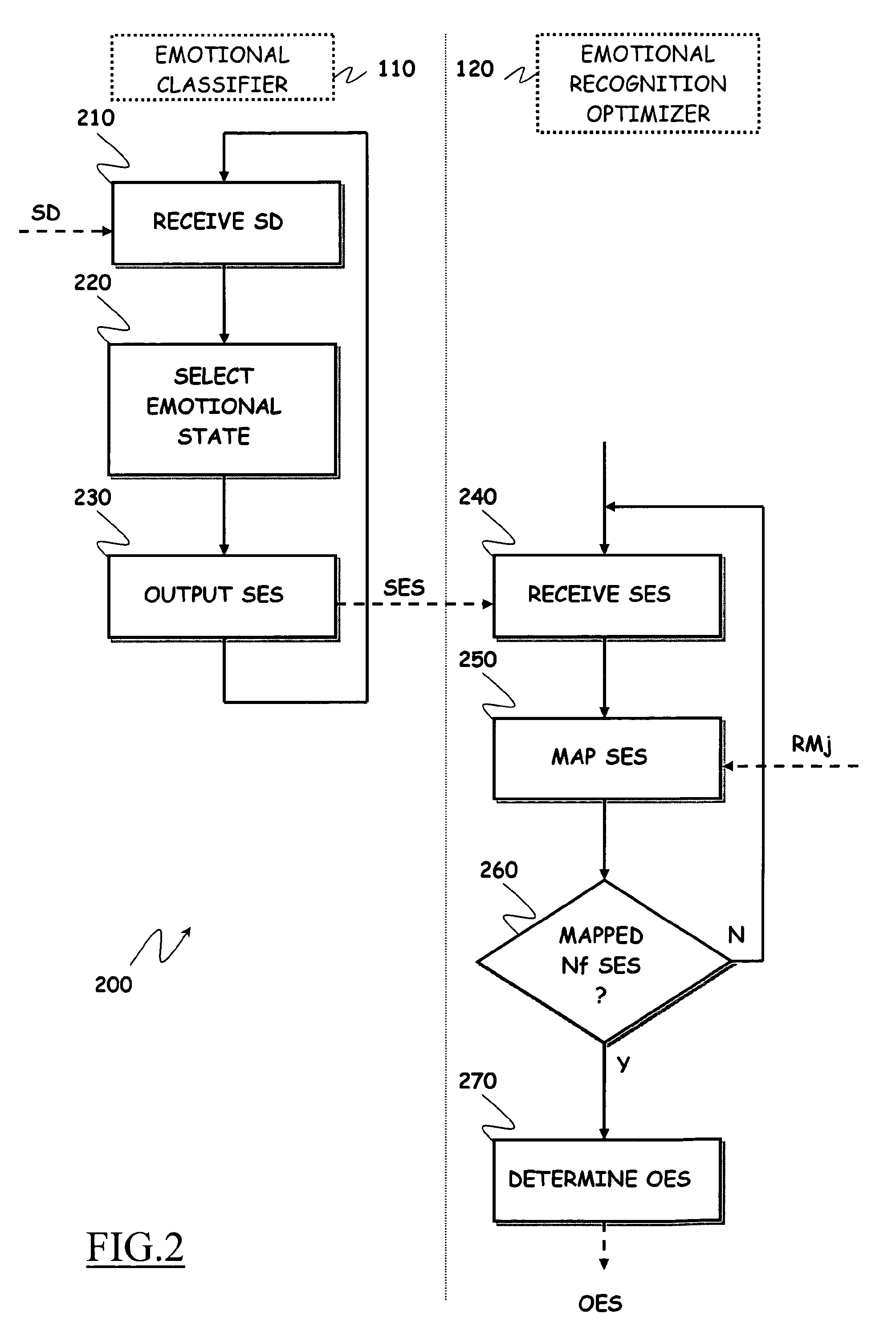

Method and system to improve automated emotional recognition

InactiveUS20100030714A1Improve efficiencySpeech analysisDigital computer detailsState representationMood state

An automated emotional recognition system includes an emotional state classifier adapted to receive, during an operative phase, an input information stream with embedded information related to emotional states of a person, and to generate a succession of emotional state indications derived from the input information stream. The emotional recognition system further includes a post-processing function, configured to receive at least two emotional state indications of the succession and, for each of said at least two emotional state indications, determine a corresponding emotional state representation in an emotional state representation system. The post-processing function is further configured to combine the emotional state representations of the at least two emotional state indications to obtain an output emotional state indication.

Owner:TELECOM ITALIA SPA

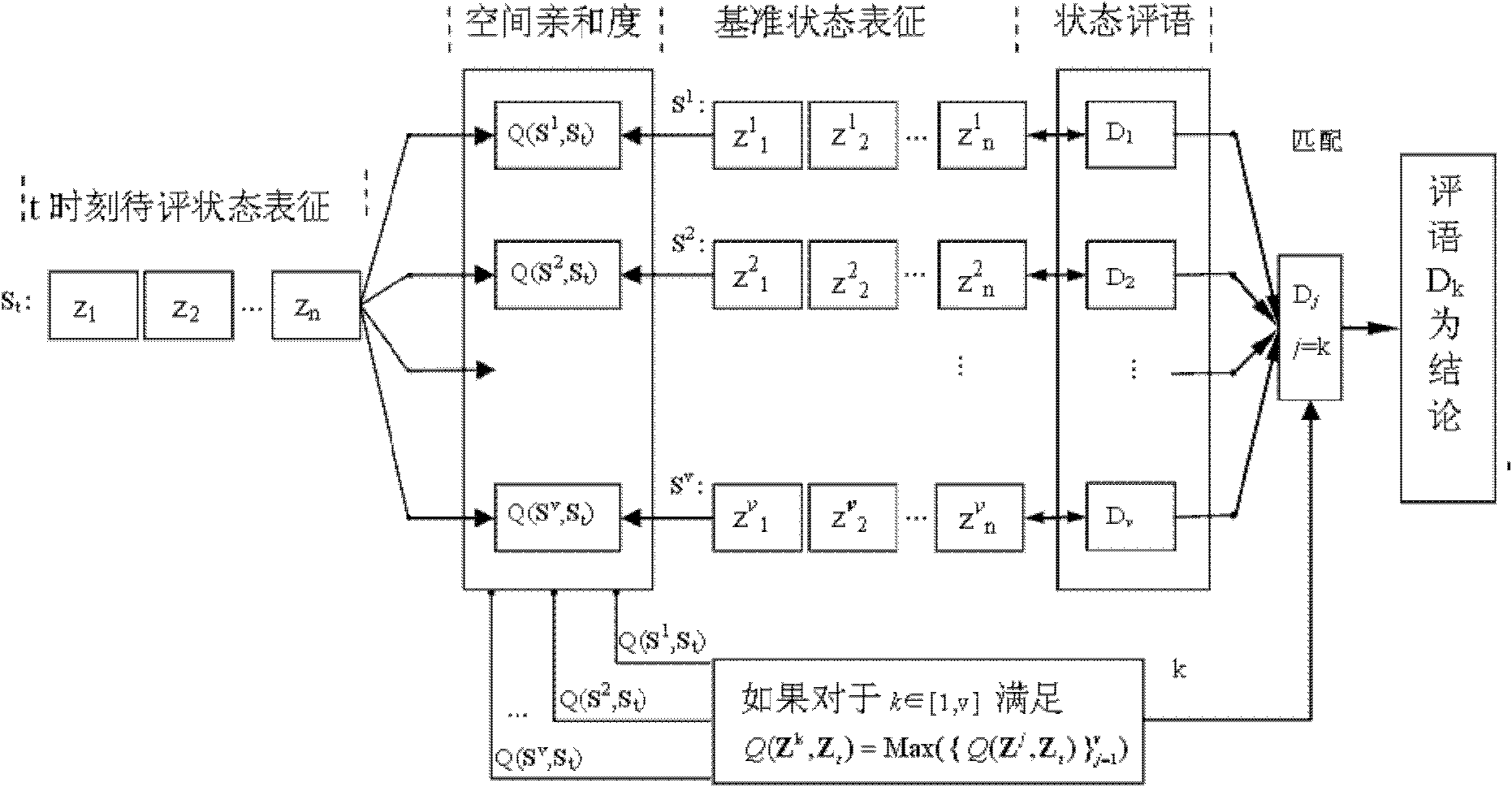

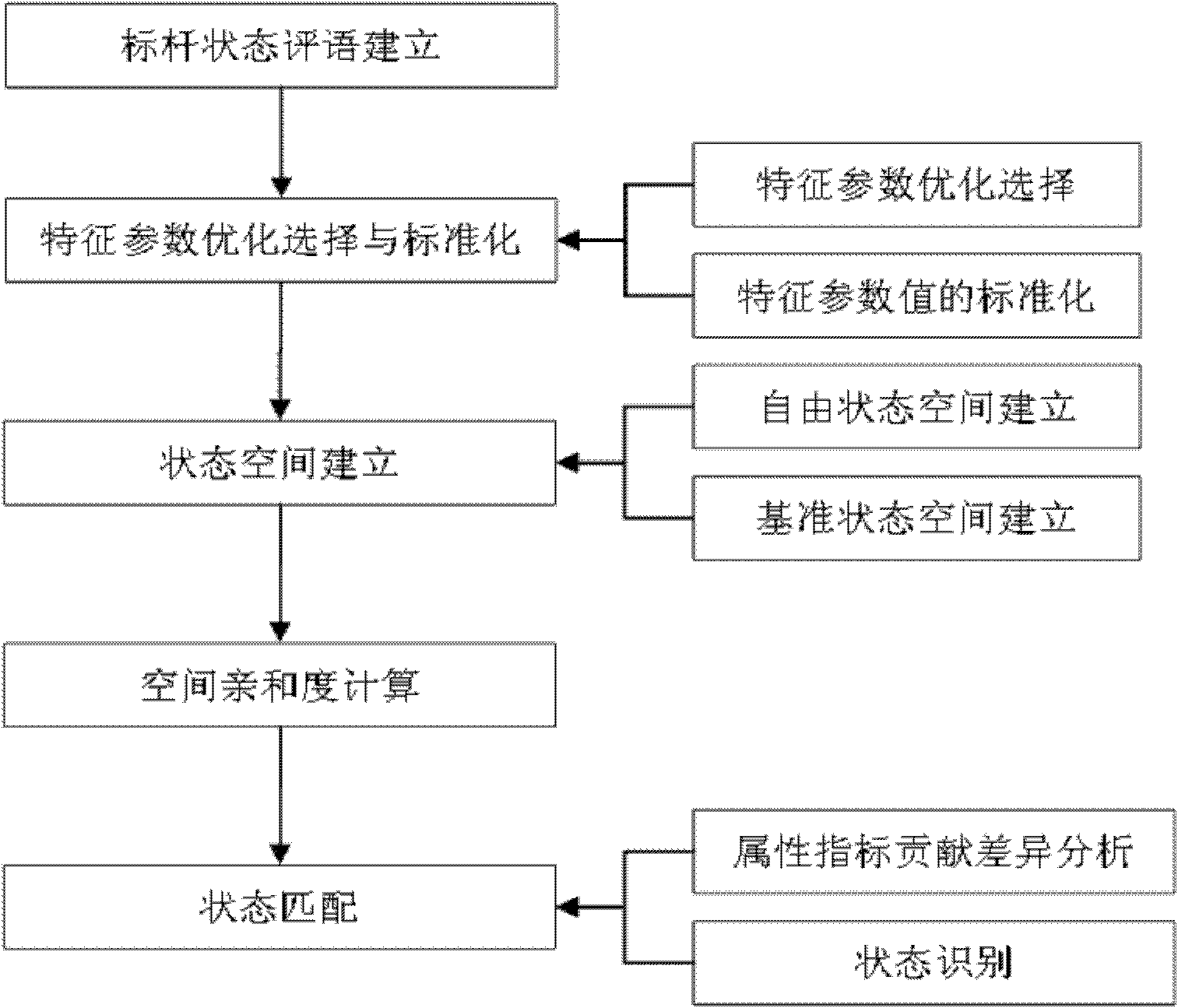

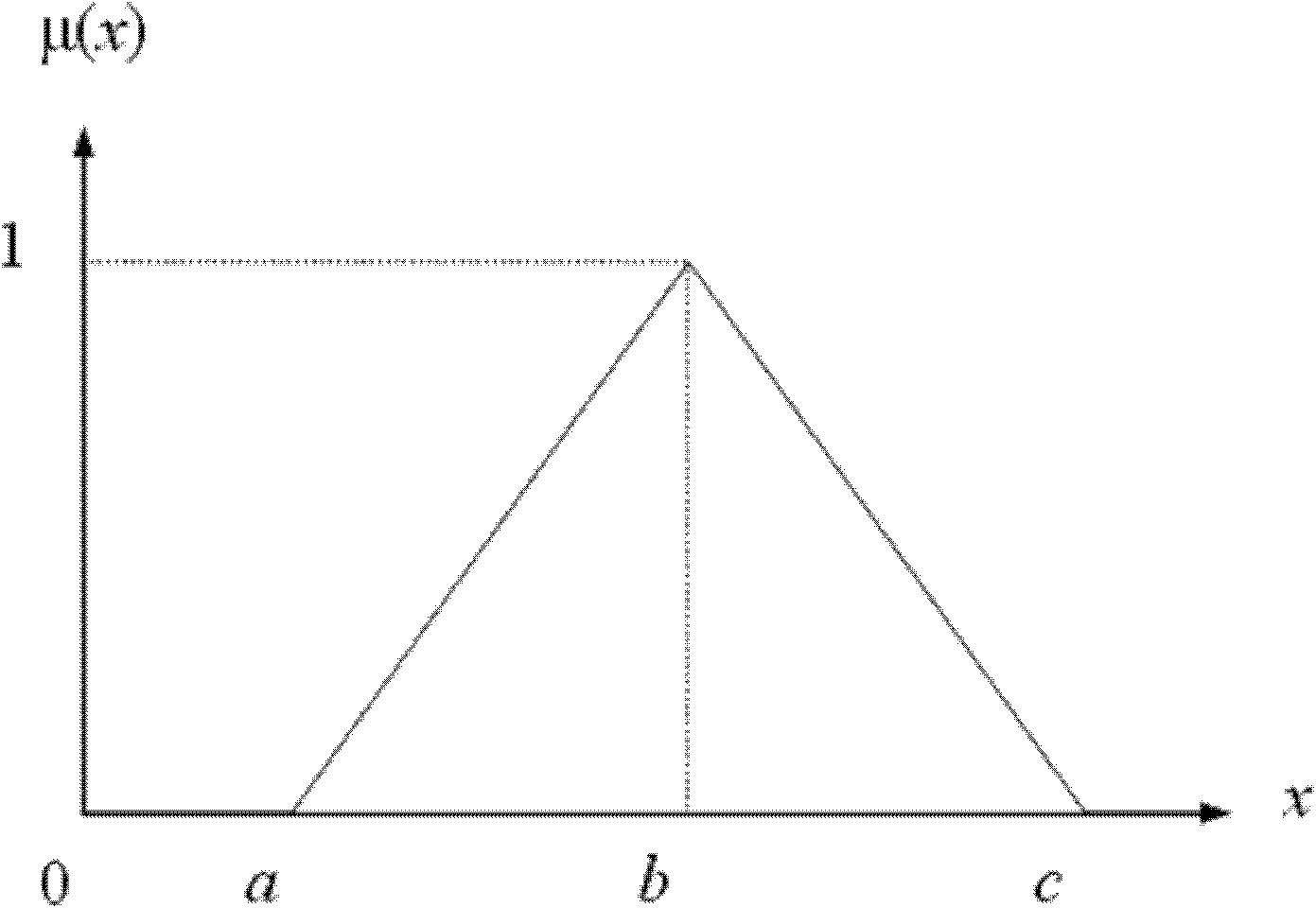

State space-based multi-featured device state evaluation method and application

InactiveCN102136038AState evaluation is scientific and comprehensiveAvoid the pitfalls of one-sided evaluationShaftsMachines/enginesEvaluation resultState space

The invention discloses a state space-based multi-featured device state evaluation method and application, belonging to the technical field of device state monitoring. The method comprises the following steps: a marker post state comment set building link provides an evaluation output range; an optimized selection and standardization link for feature parameters provides standardization input; a state space building link provides a state representation mode; a space affiliation calculating link provides state evaluation indexes; and a state matching link provides the final output conclusion. In the invention, the research thinking on multi-featured device state evaluation is expanded, the traditional linear distortion phenomenon caused by direct linear superposition of multi-featured utility values can be solved, the formulation of state grading standard is enriched, contribution degree of all feature elements to the state evaluation result can be quantized, a scientific method for improving the state monitoring and analysis level of complex equipment is improved, labor cost is reduced and enterprise benefit is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

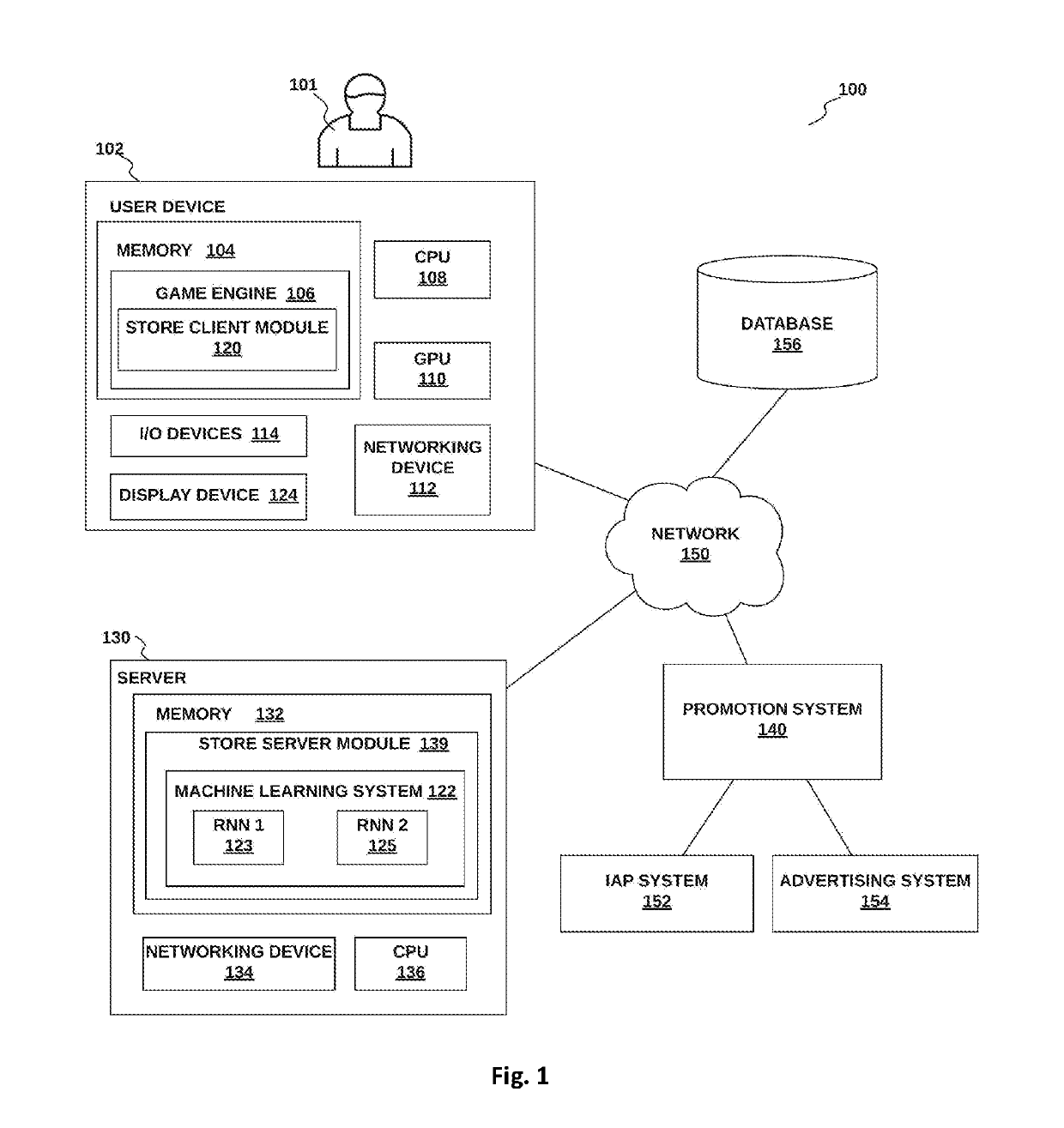

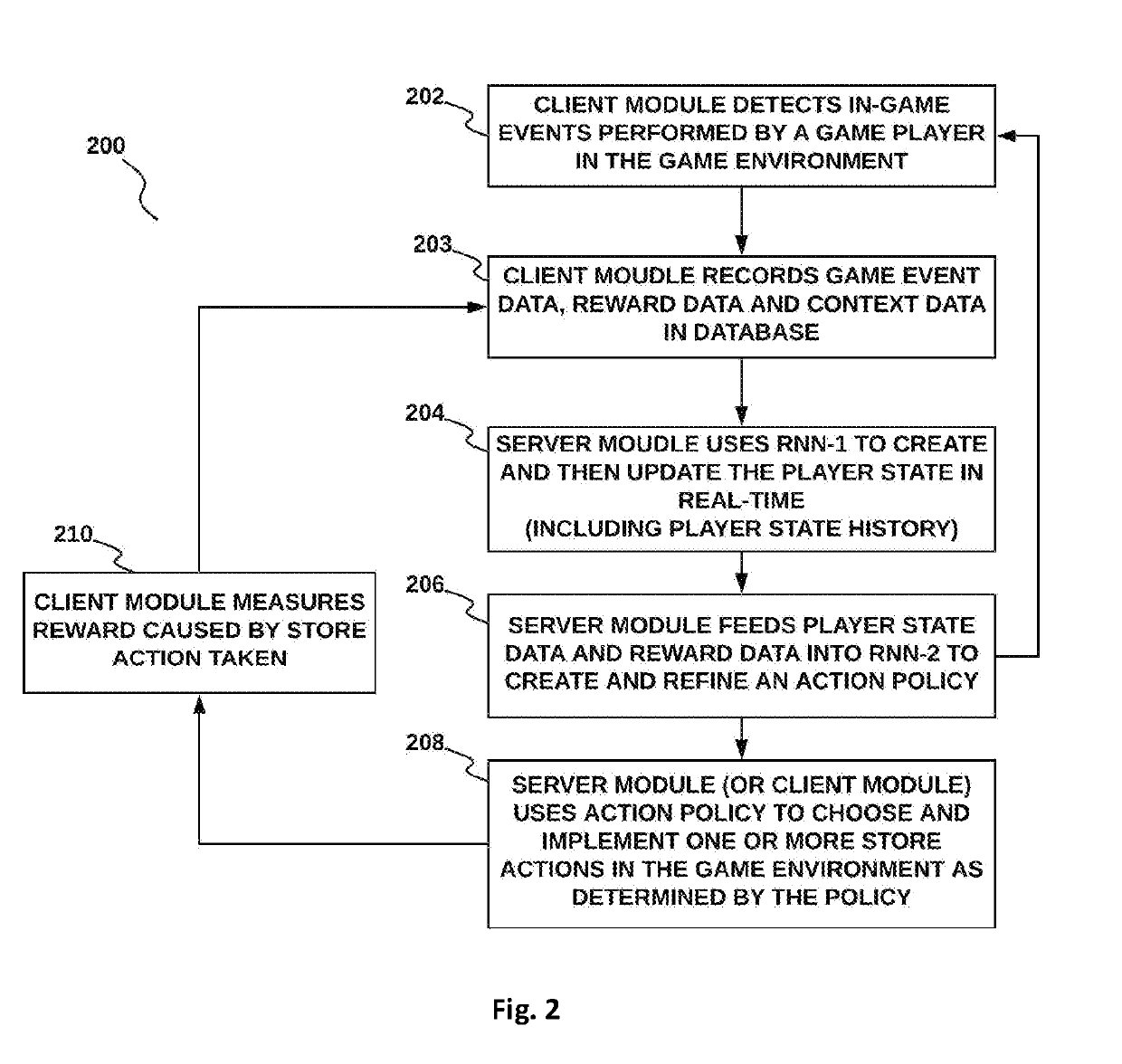

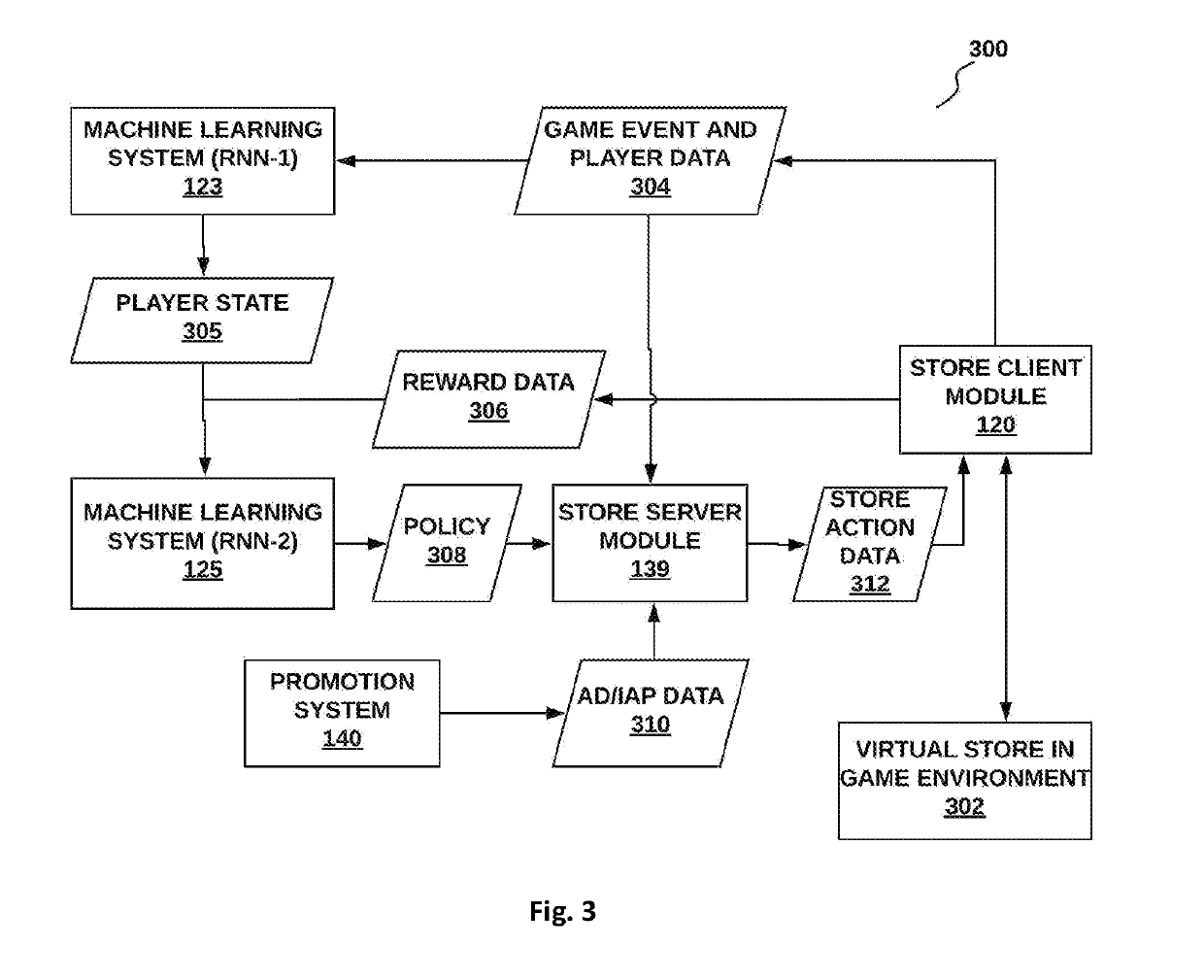

Systems and methods for a machine learning based personalized virtual store within a video game using a game engine

Systems and methods for optimizing a Lifetime Value (LTV) of a player of a plurality of computer-implemented games are disclosed. Data is collected from a game of the plurality of games, the data including game event data associated with the player, a playing environment within the game, and store action data. The data is analyzed with a first machine-learning (ML) system to create a time-dependent state representation of the game, the player, and the playing environment. The state representation is provided as input to a second ML system to create and optimize an ML policy over time, the ML policy including a functional relationship proposing a selection of one or more store actions within a store to maximize the LTV. One or more of the store actions chosen from the proposed selection in accordance with the ML policy and implemented within the store environment.

Owner:UNITY TECH SF

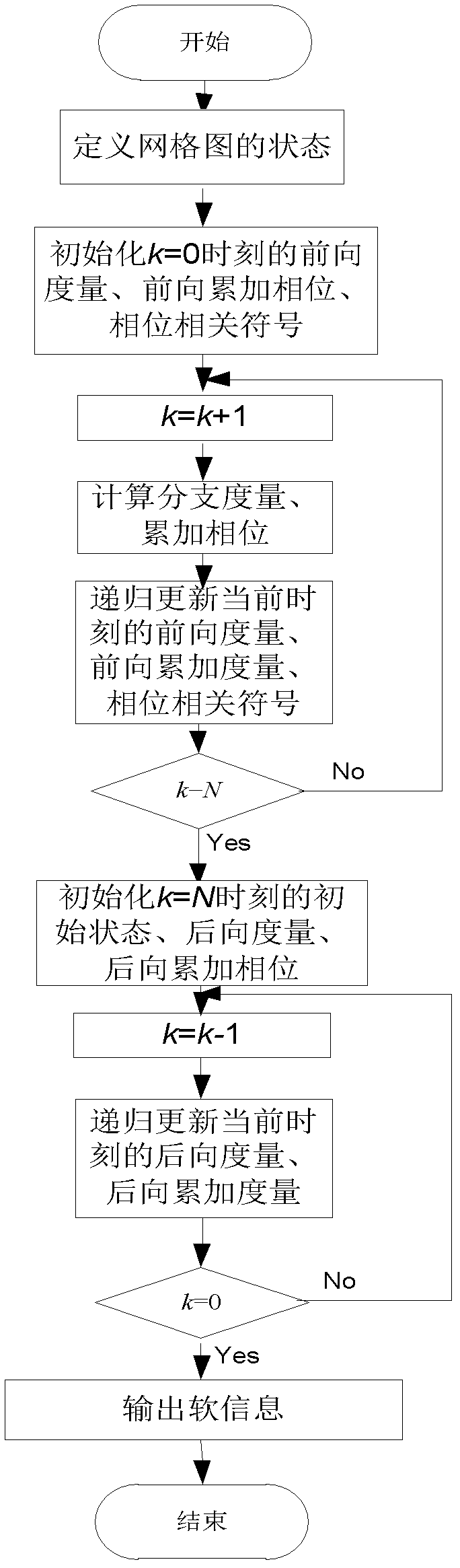

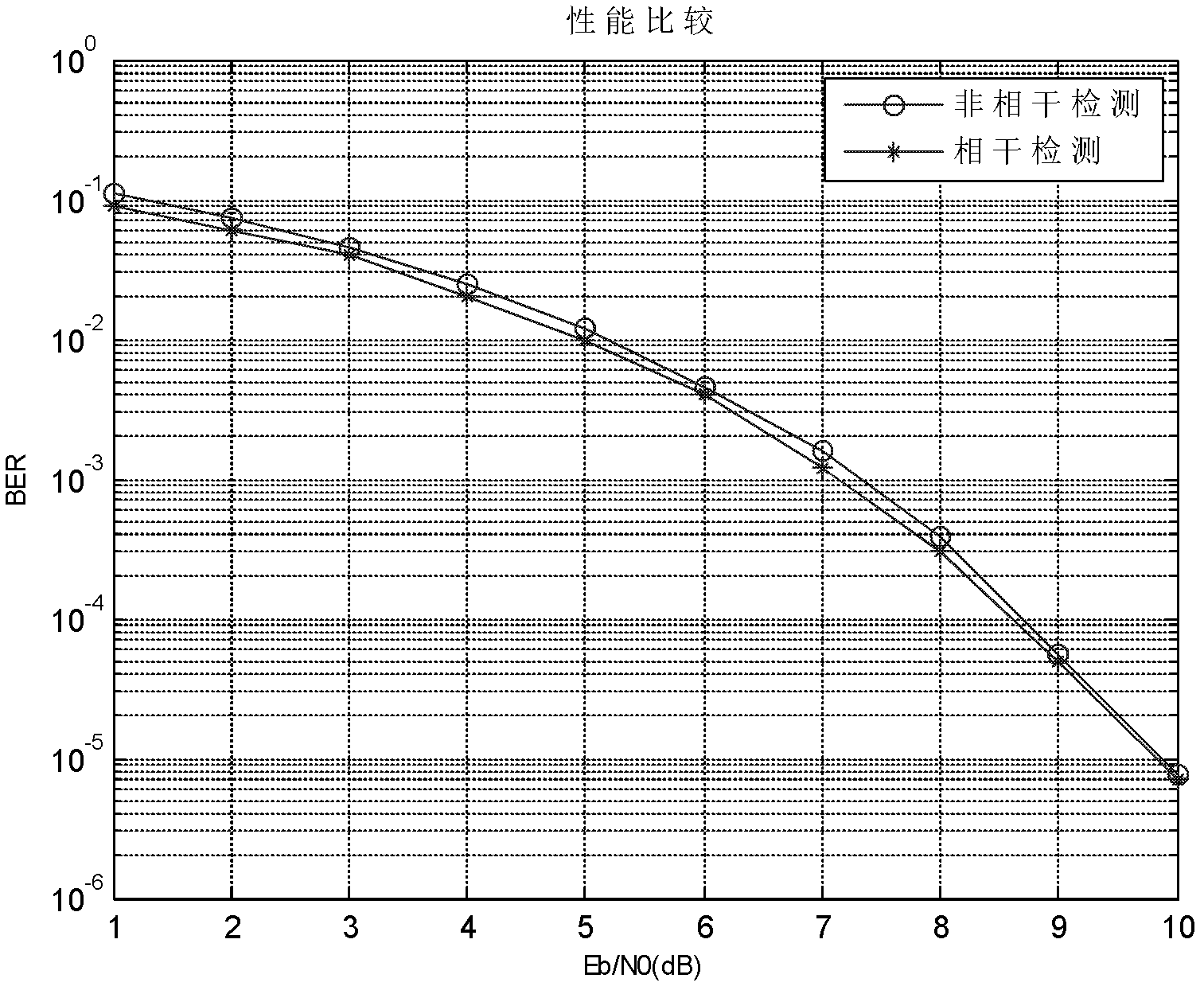

Incoherent soft-output detection method based on continuous phase modulation

InactiveCN102594755AOvercoming phase requirementsReduce Detection ComplexityModulated-carrier systemsPrior informationAlgorithm

The invention discloses an incoherent soft-output detection method based on continuous phase modulation system, and mainly overcomes the defects that the existing incoherent detection is high in complexity and insufficient in detection performance. The method is implemented through the following steps: (1) defining state representations in a grid chart; (2) setting a moment before receiving as a moment receiving the zeroth symbol, and carrying out forward initialization on all states at the current moment; (3) sequentially carrying out forward updating from a moment receiving the first symbol to a moment receiving the Nth symbol in an ascending mode; (4) after the forward updating is completed, carrying out backward initialization on all states at the moment receiving the Nth symbol; (5) sequentially carrying out backward updating from a moment receiving the (N-1)th symbol to a moment receiving the zeroth symbol in a descending mode; and (6) after the forward updating and the backward updating are completed, merging prior information of a forward metric, a backward metric, a branch metric and input symbols, and outputting soft information. The method disclosed by the invention can be applied to the detection of an uncoded system and the simultaneous iterative detection in a serial concatenated system.

Owner:XIDIAN UNIV

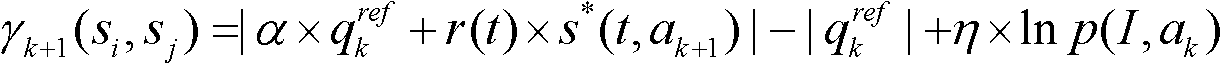

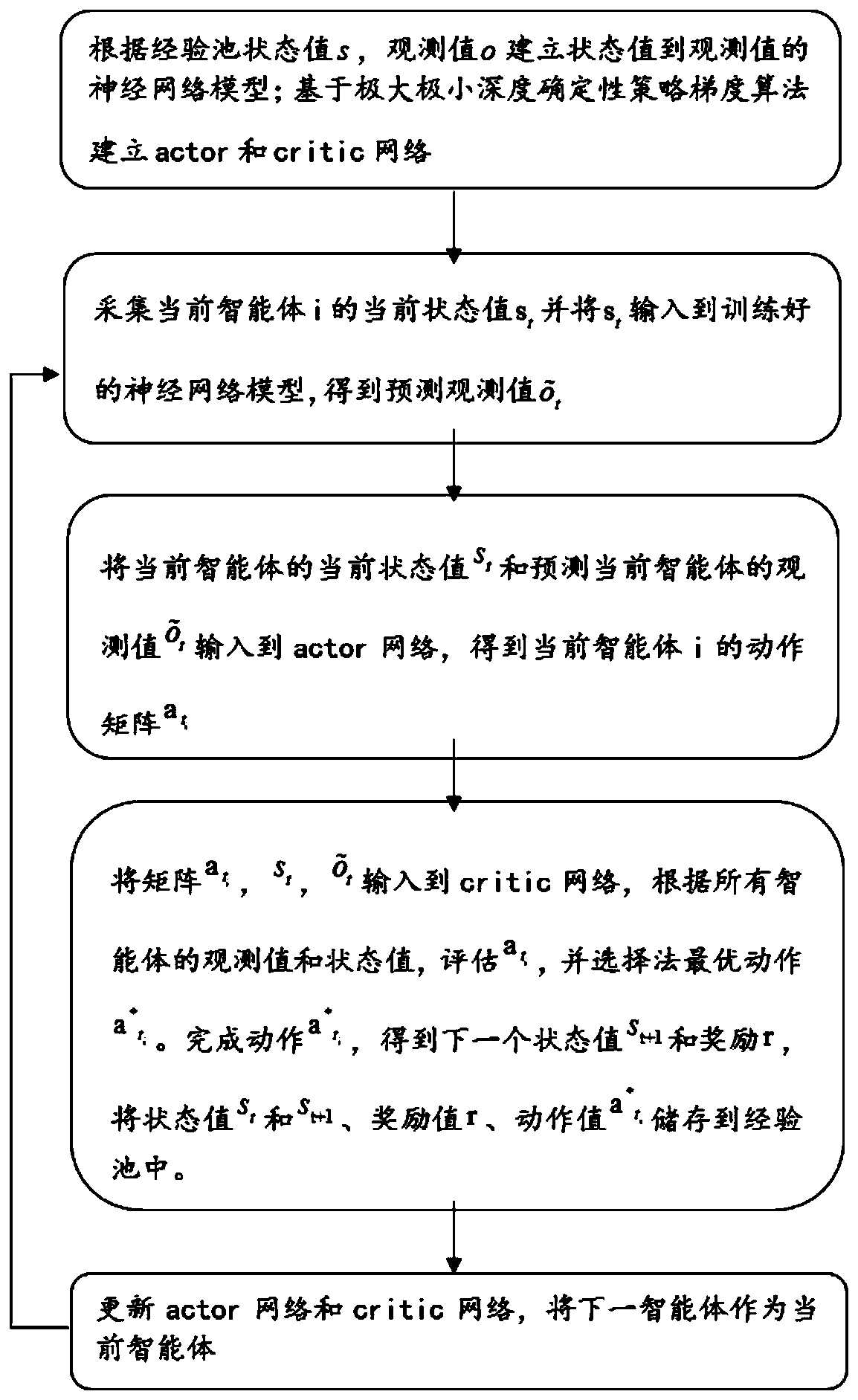

Multi-agent cooperative control system and method for process industry

InactiveCN110427006AReduce the number of acquisition and processing stepsAchieve real-time dynamic optimizationTotal factory controlProgramme total factory controlState representationMachine learning

The invention provides a multi-agent cooperative control system and method for the process industry. A neutral network model from state values to observation values is arranged for feature extraction,important features of data are better extracted, and processing of mass data or even high-dimensional data can be adapted to. Then the minimax deep deterministic policy gradient algorithm is adoptedfor learning, wherein actor and critic networks in the minimax deep deterministic policy gradient algorithm conduct learning from a new neural network instead of conducting learning from initial observation. By means of the method for conducting state representation learning by utilizing the neutral network, the network can well capture features, and the adaptability to data is higher.

Owner:QILU UNIV OF TECH

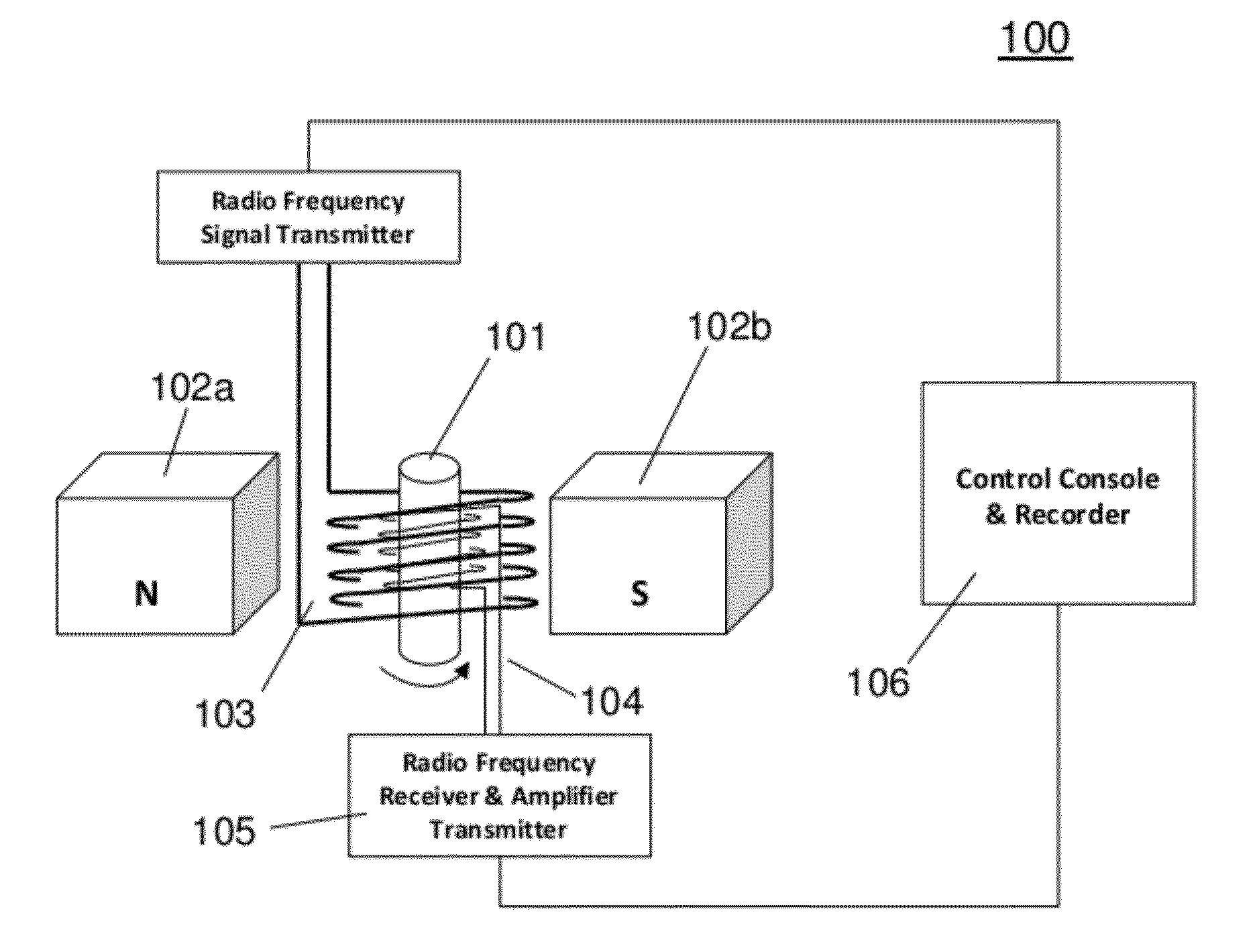

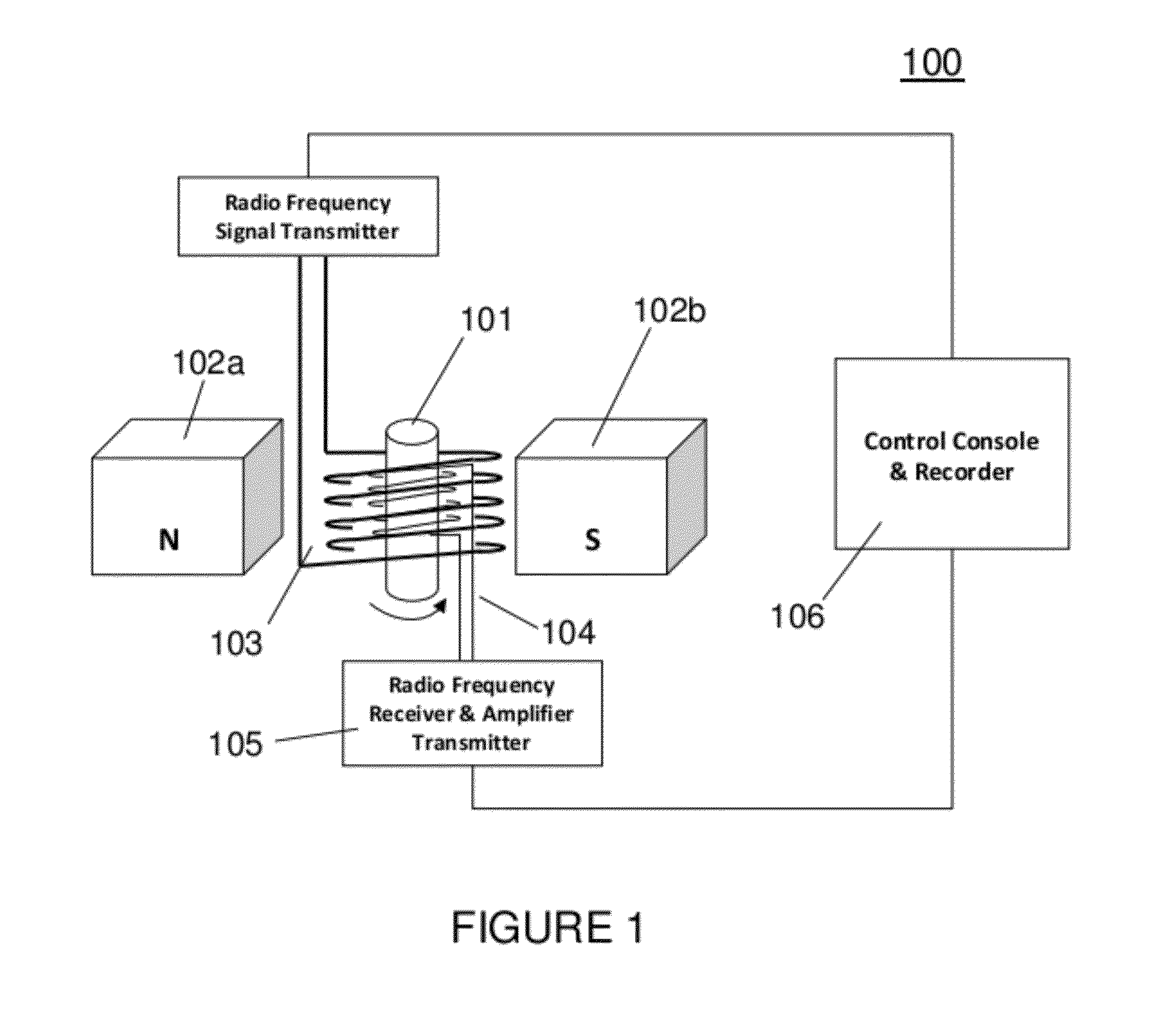

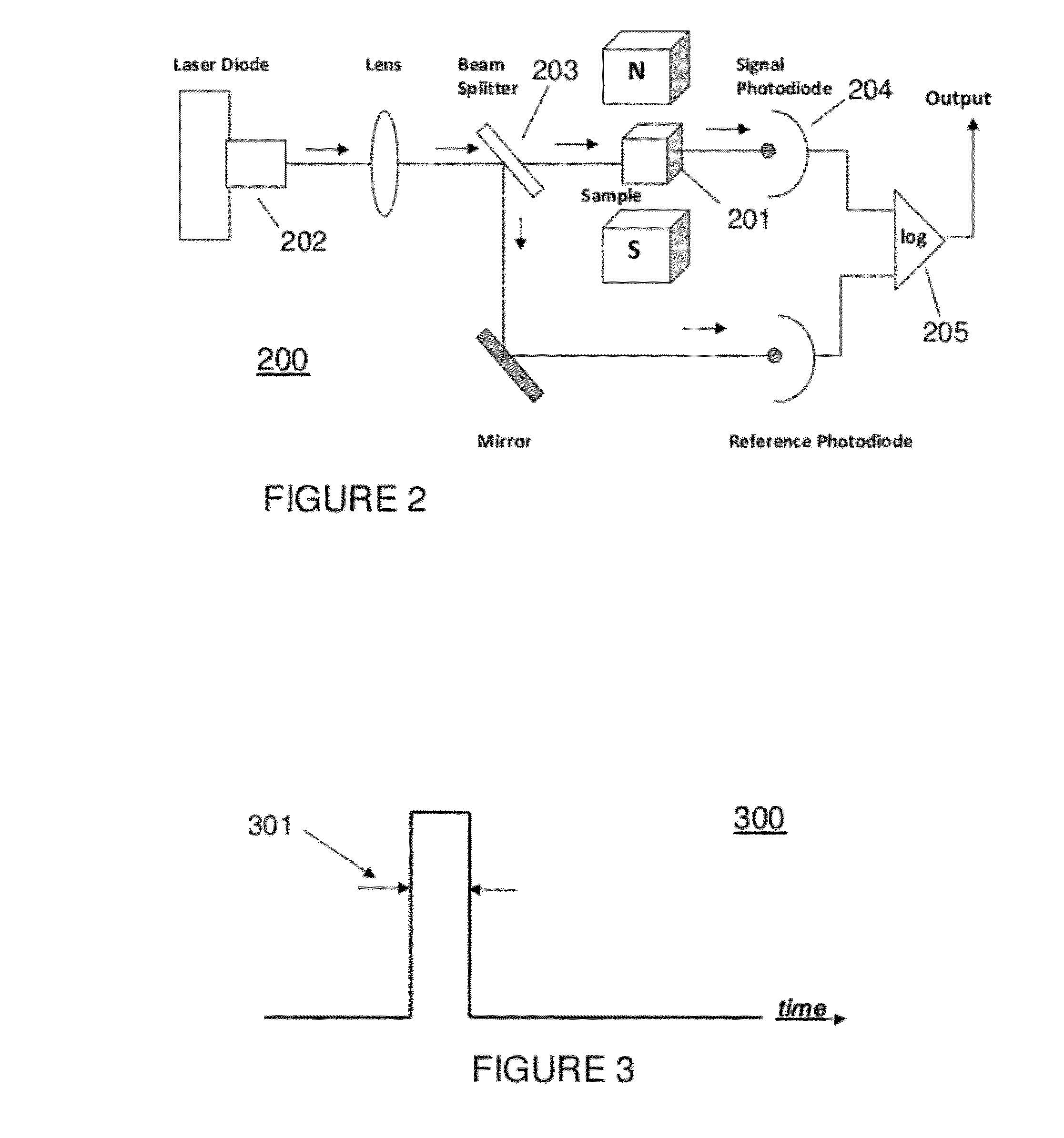

System and method of quantum computing using three-state representation of a qubit

ActiveUS8374994B2Quantum computersSemiconductor/solid-state device detailsState representationQuantum computer

A method (and structure) of quantum computing. Two independent magnitudes of a three-state physical (quantum) system are set to simultaneously store two real, independent numbers as a qubit. The three-state physical (quantum) system has a first energy level, a second energy level, and a third energy level capable of being degenerate with respect to one another, thereby forming basis states for the qubit.

Owner:IBM CORP

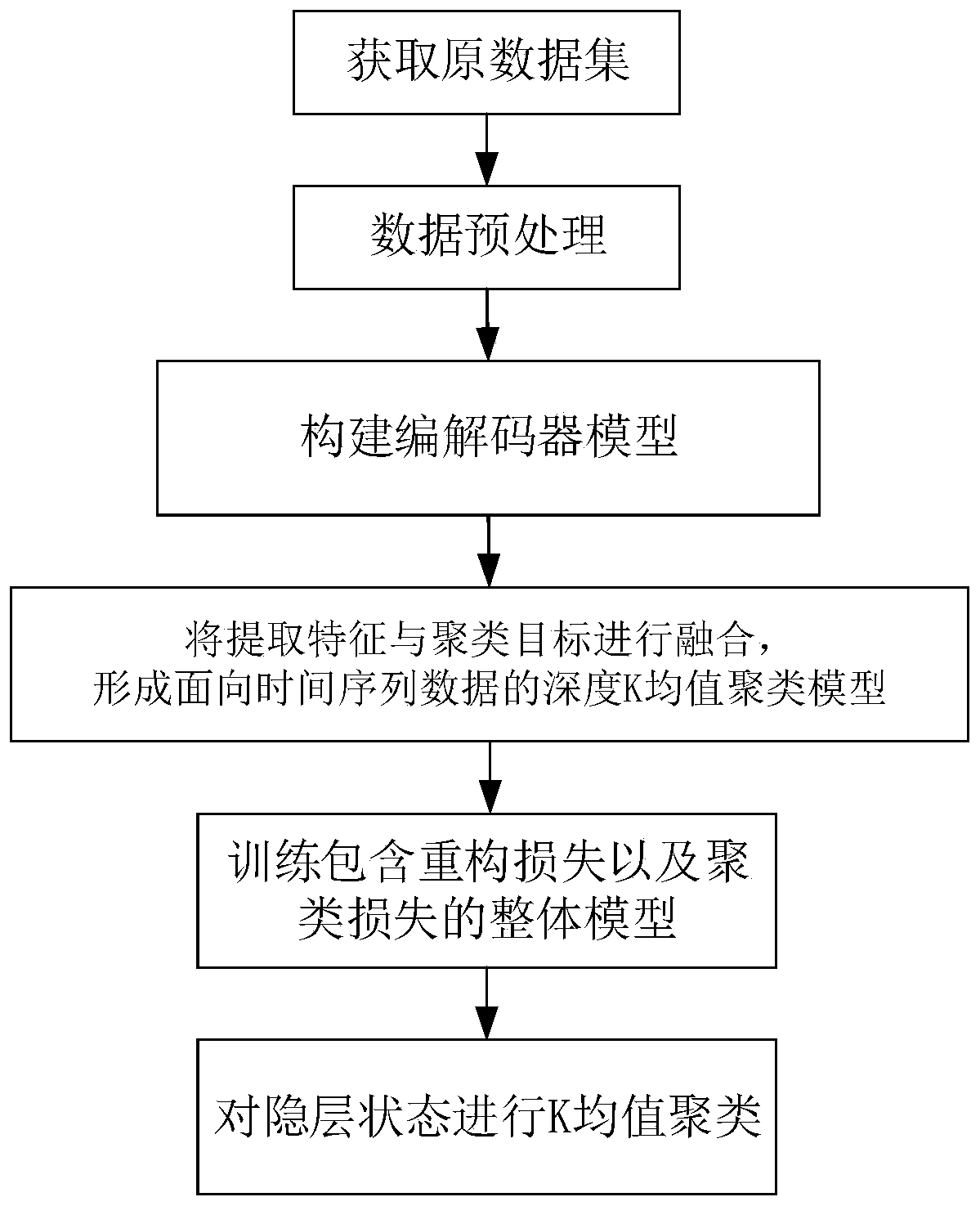

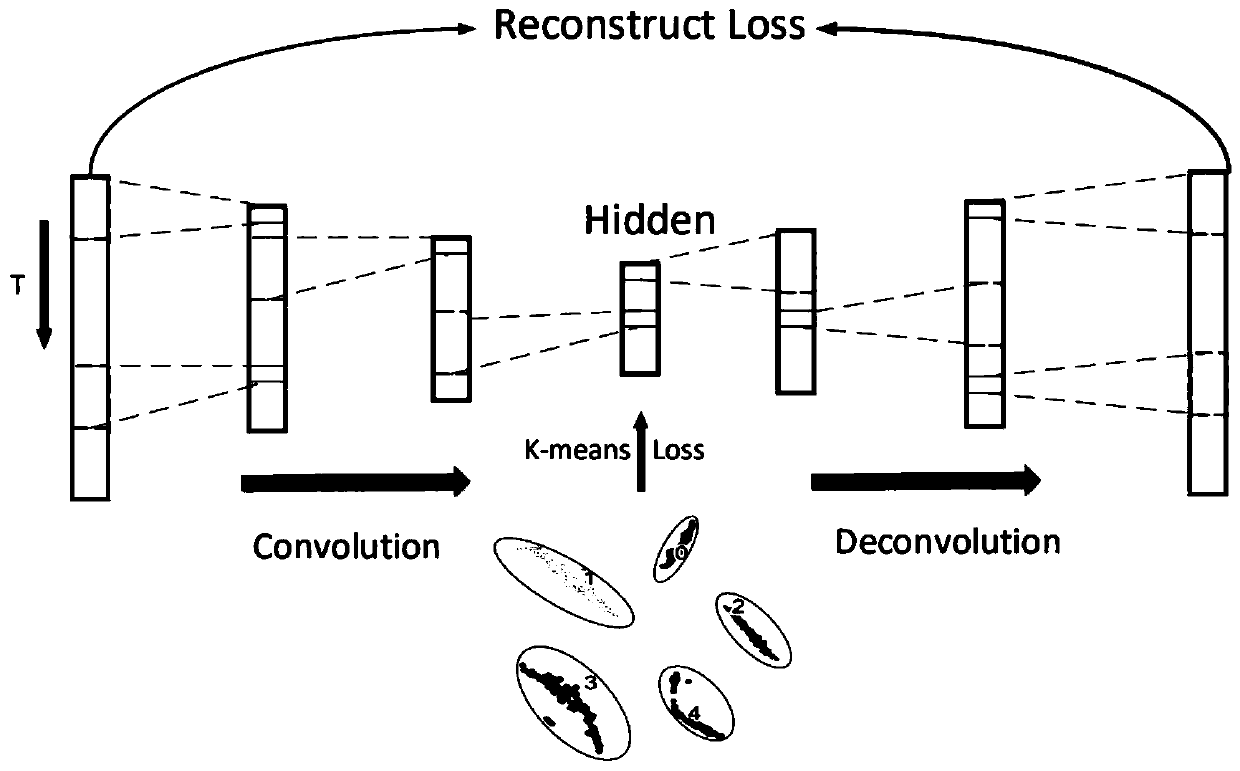

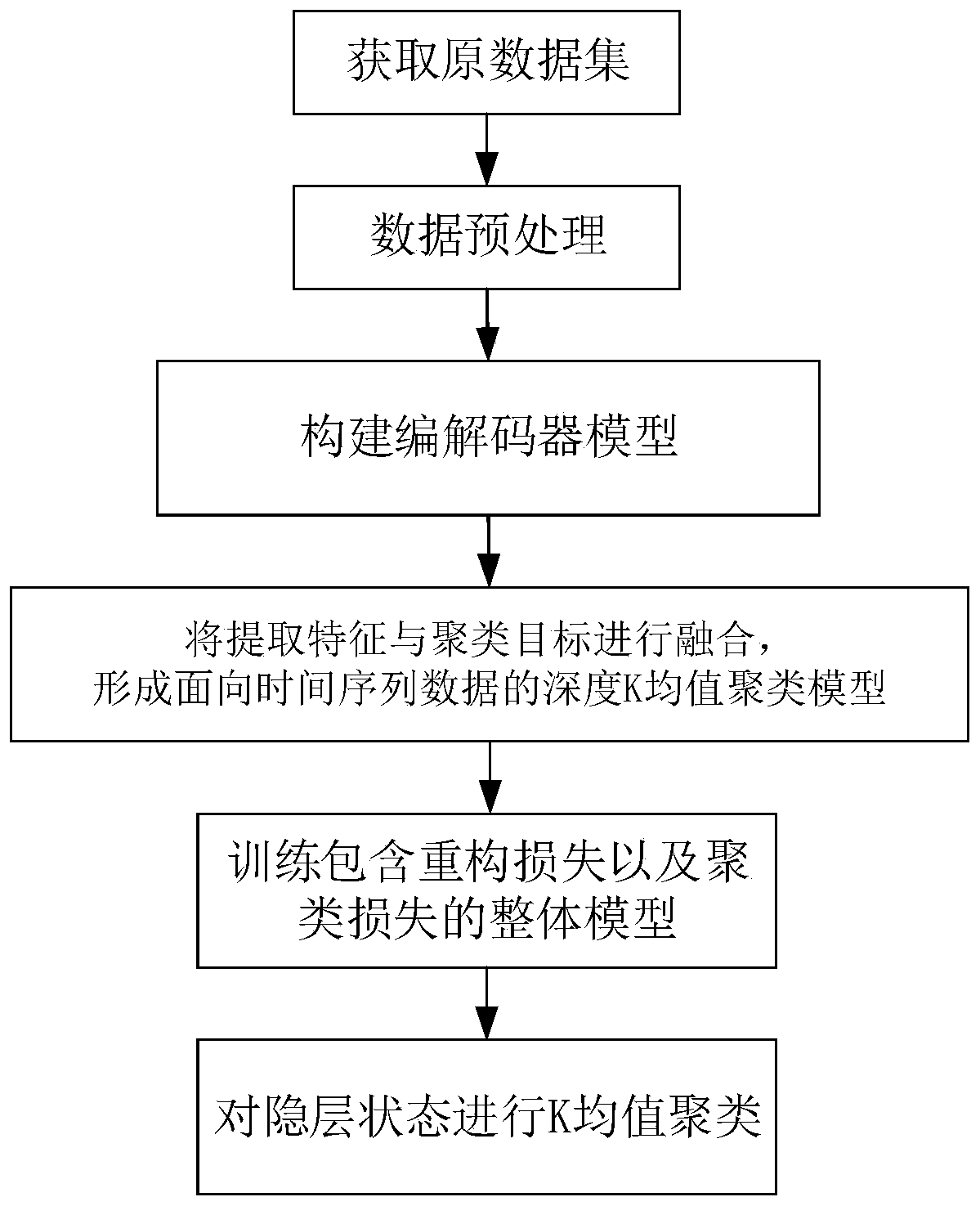

A depth K-means clustering method for time series data

InactiveCN109919189AHigh precisionPromote formationCharacter and pattern recognitionData setState representation

The invention discloses a depth K-means clustering method for time series data, which comprises the following steps of: obtaining a time sequence data set, preprocessing the time sequence data set, separating sample information and category information of data, and inputting the sample information of the data into a model; constructing a codec model, and adopting a convolution-deconvolution framework; Introducing the K-means clustering loss into a codec model to form a depth K-means clustering model facing the time series data, and fusing the extracted features with the clustering target; Training the constructed model by utilizing a back propagation algorithm, and guiding generation of a hidden layer state; Finally, performing k-means clustering based on the hidden layer state representation generated by the training process, and calculating the rand index index.. By fusing the extracted features with the clustering target, the generated hidden layer state not only can reconstruct theoriginal sample, but also is beneficial to the formation of a cluster-shaped structure, so that the clustering operation is better carried out, and the clustering precision is improved.

Owner:SOUTH CHINA UNIV OF TECH

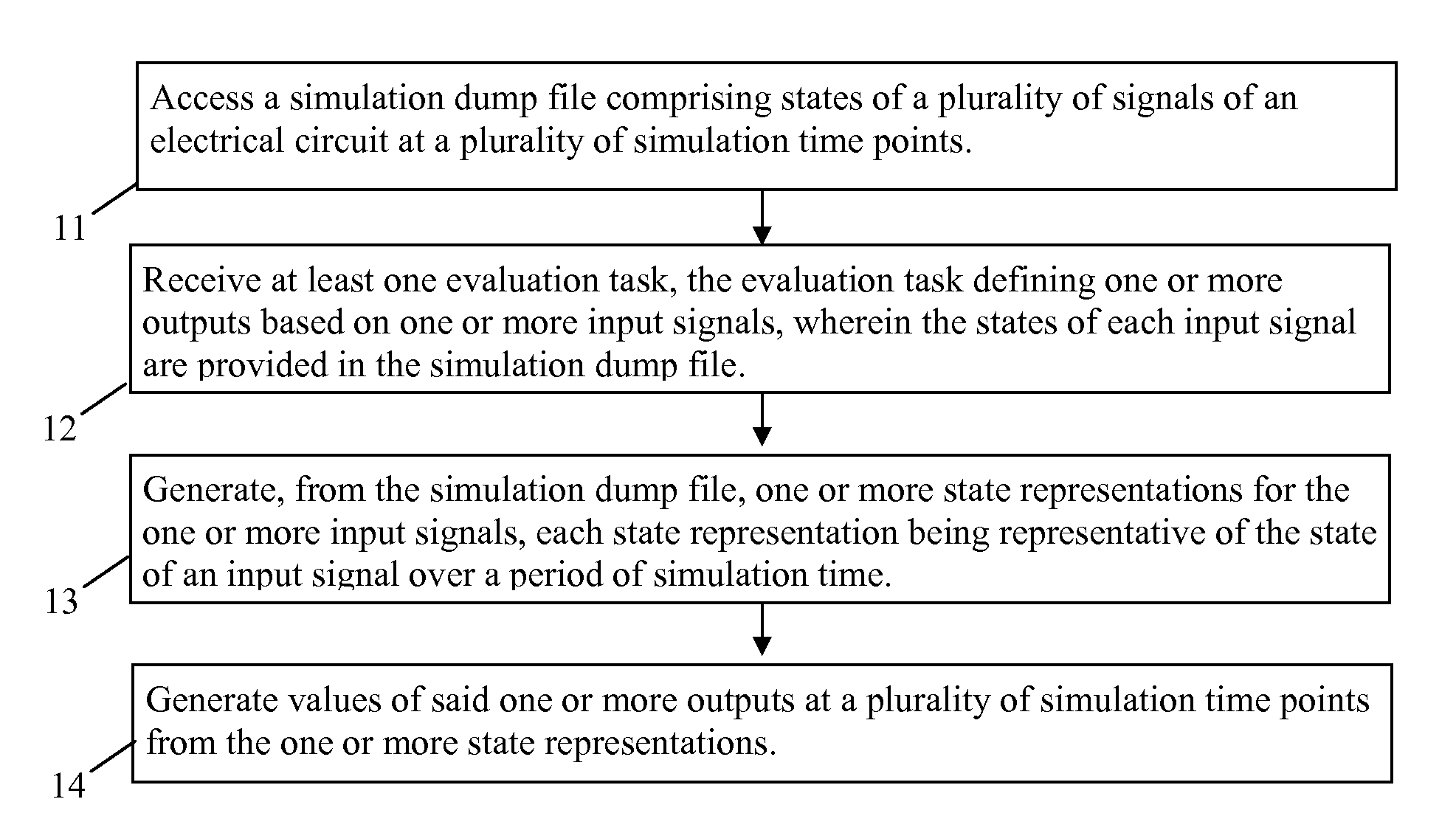

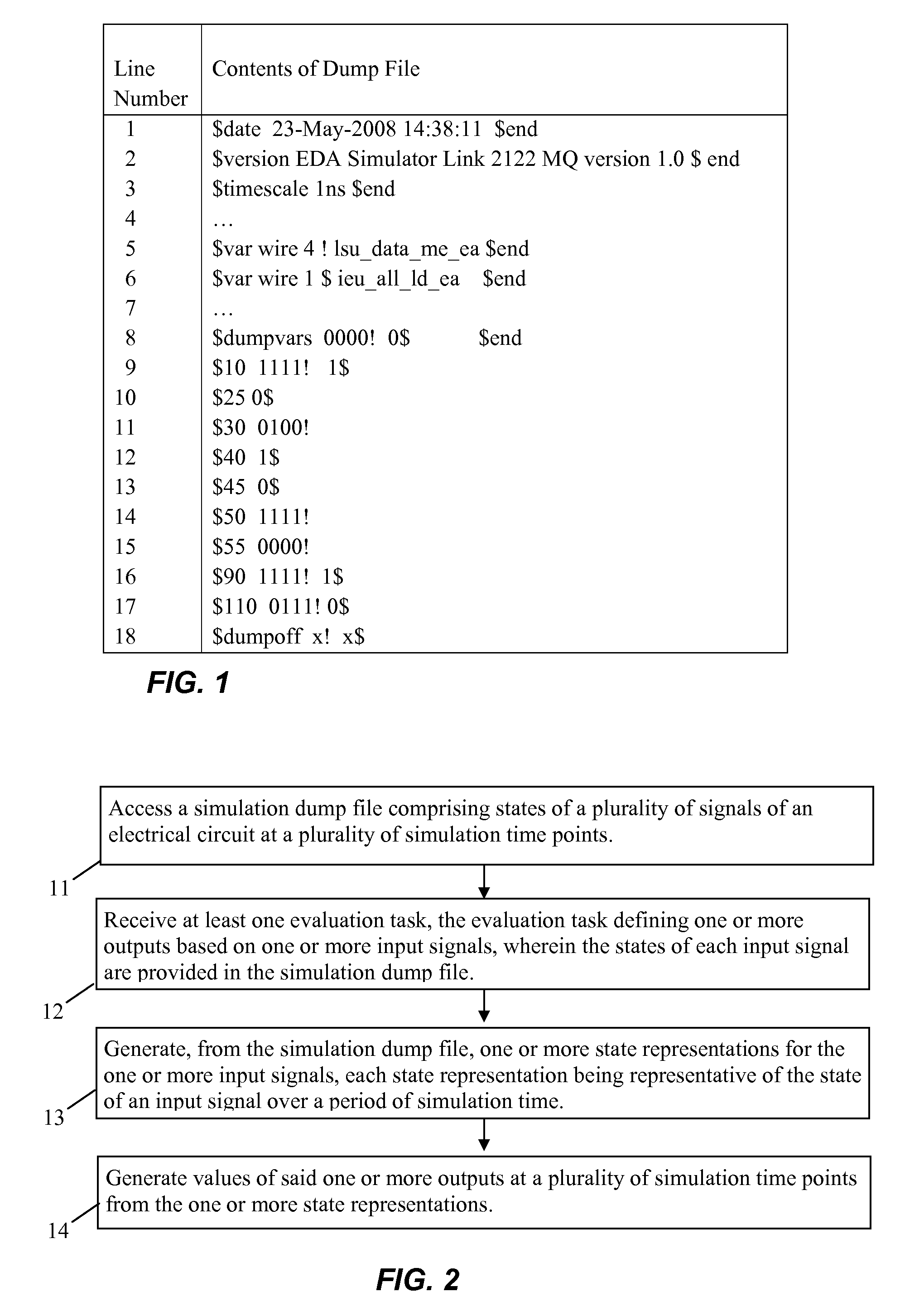

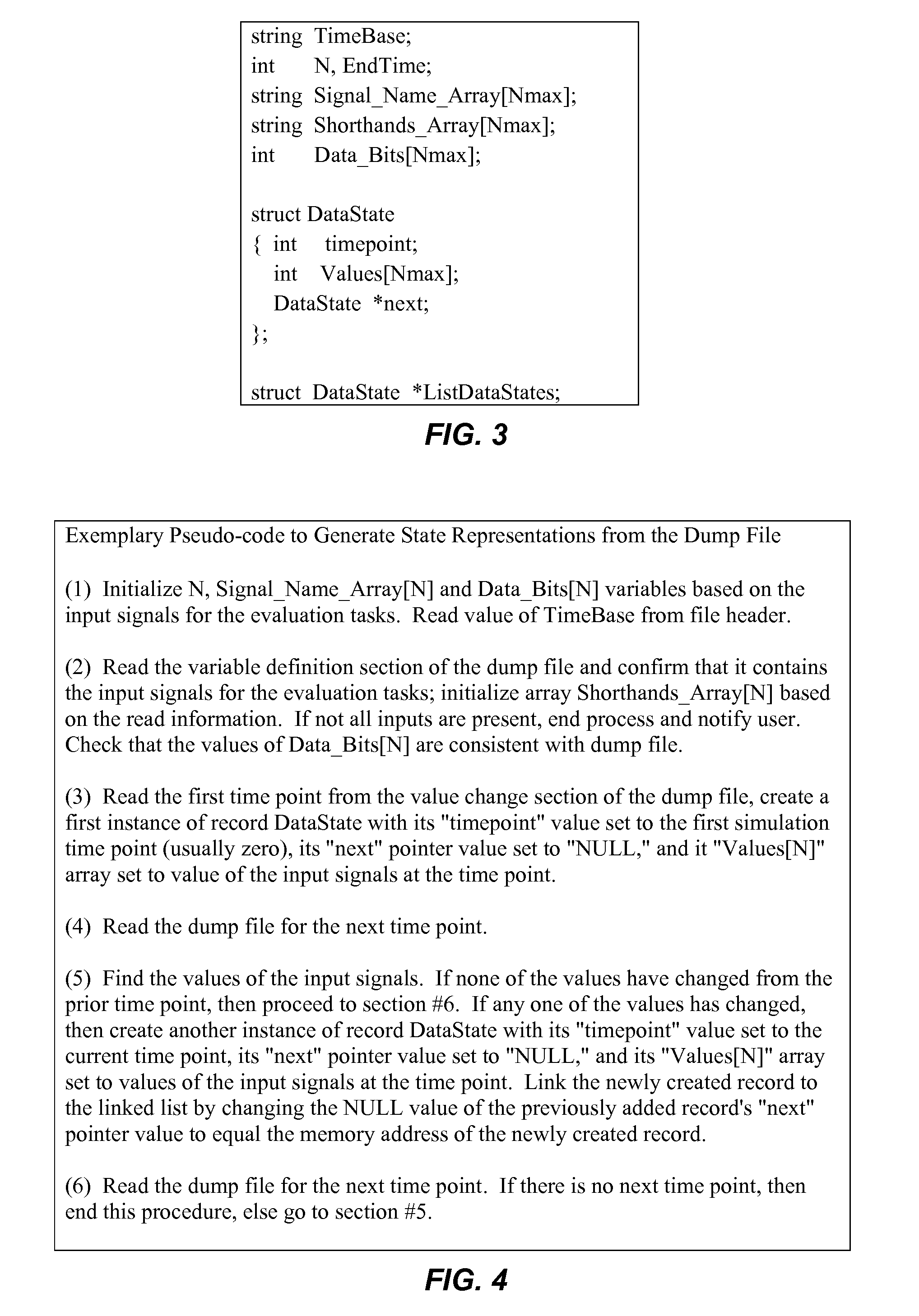

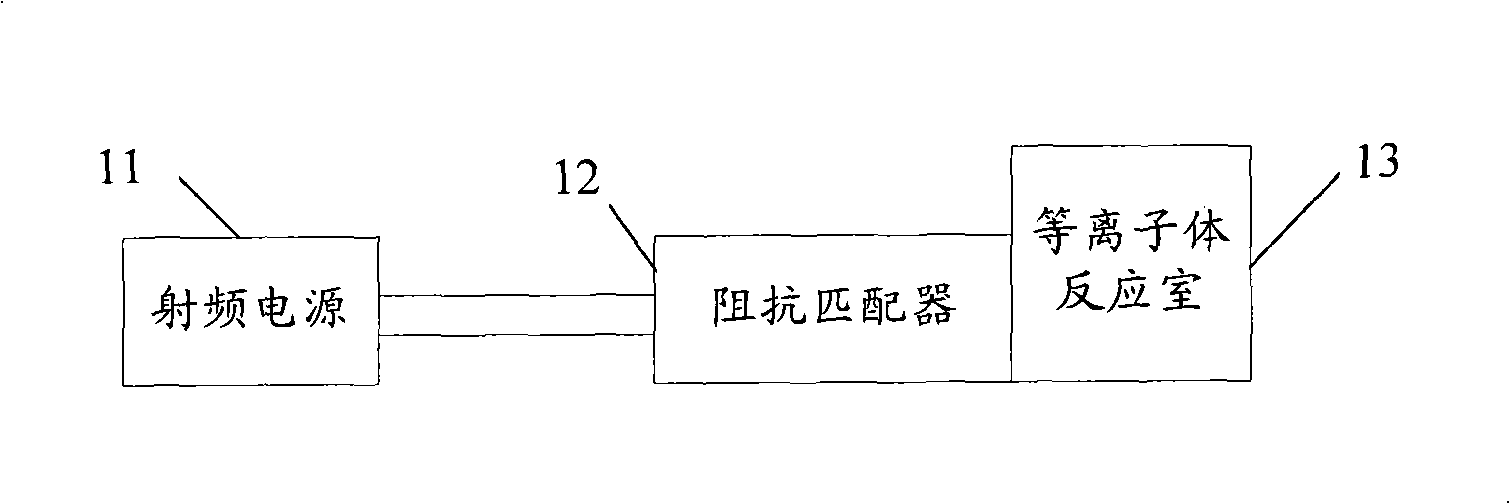

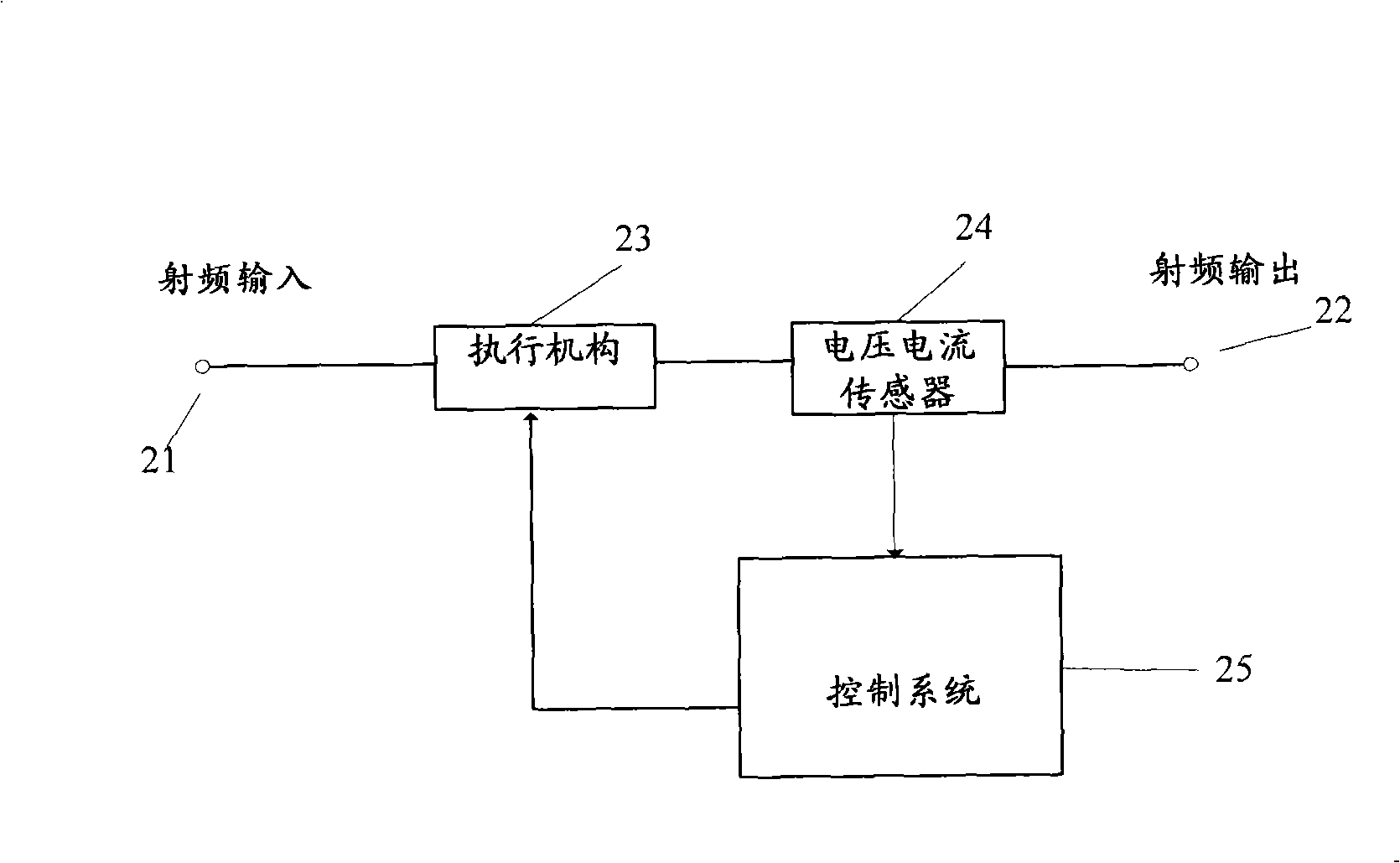

Methods, Systems, and Computer Program Products for Evaluating Electrical Circuits From Information Stored in Simulation Dump Files

InactiveUS20100070257A1Information can be usedMany problemCAD circuit designSpecial data processing applicationsState representationComputer science

Disclosed are methods, systems, and computer program products for evaluating performance aspects of electrical circuits, and particularly digital logic circuits. An exemplary method comprises obtaining access to a simulation dump file comprising state indications of the values of a plurality of signals of an electrical circuit at a plurality of simulation time points, and receiving an evaluation task that defines an output based on one or more input signals, with each input signal being a signal for which state indications are provided in the simulation dump file. The method further comprises generating, from the simulation dump file, one or more state representations for the input signals of the evaluation task, with each state representation being representative of the state of an input signal over a period of simulation time, and generating values of the output of the evaluation task at a plurality of simulation time points from the state representations.

Owner:ARM FINANCE OVERSEAS LTD

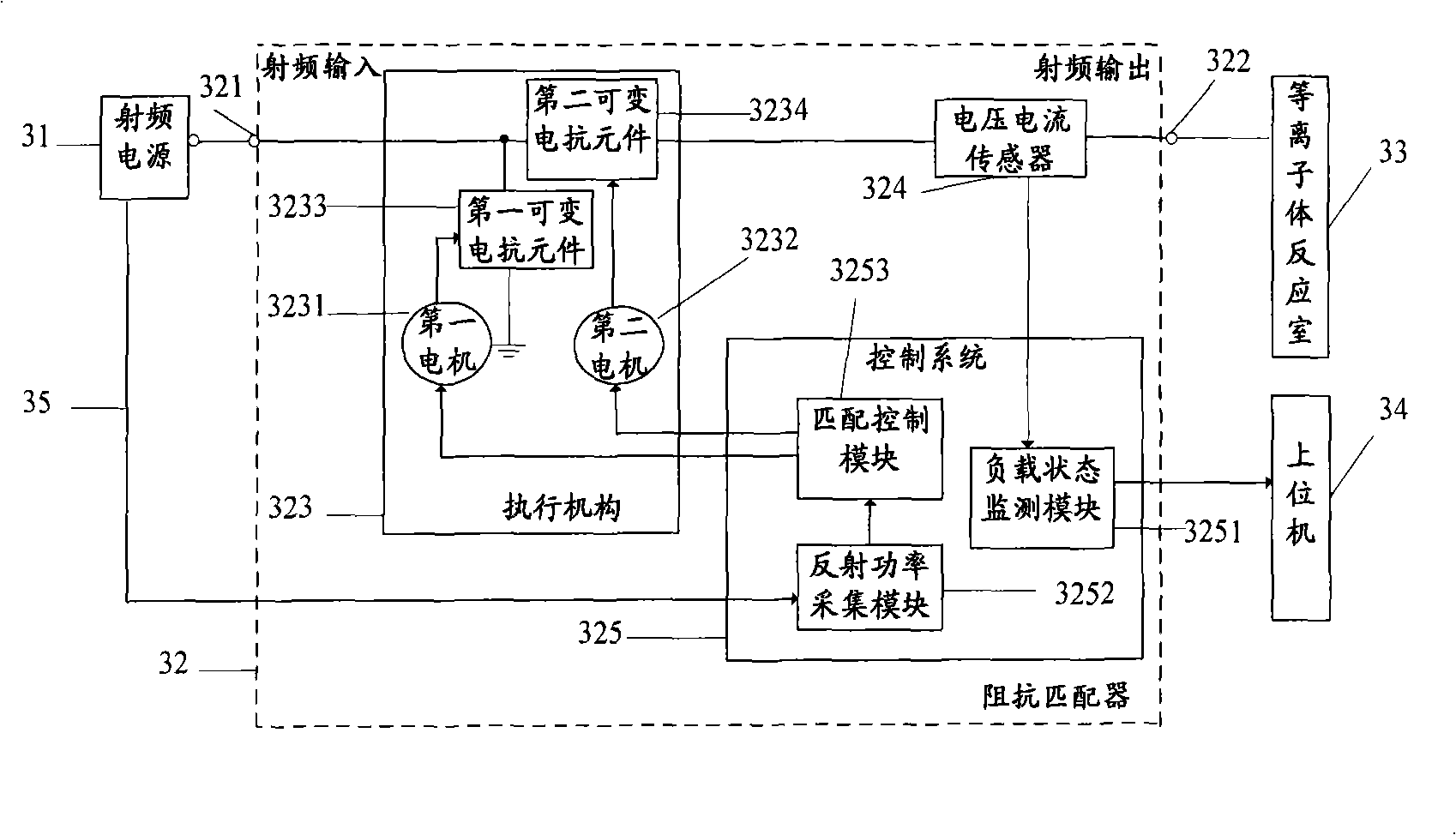

Impedance matcher

ActiveCN101494946ASemiconductor/solid-state device manufacturingPlasma techniqueControl signalControl system

The invention provides an impedance matching device, which comprises: a voltage current sensor for monitoring impedance state in plasma reaction chamber and outputting plasma reaction chamber impedance state representation signal to control system; a control system for generating control signal according to before determined matching control method, driving actuating mechanism to adjust radio frequency power supply load impedance, and realizing the matching of radio frequency power supply output impedance and radio frequency power supply load impedance; acquiring the plasma reaction chamber impedance state representation signal from the voltage current sensor, and calculating plasma reaction chamber impedance value according to the plasma reaction chamber impedance state representation signal; and a actuating mechanism for receiving control signal of control system, and adjusting the radio frequency power supply load impedance according to the control signal. By adopting the above technical scheme, the invention realizes accurate monitoring to radio frequency power supply load impedance state.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

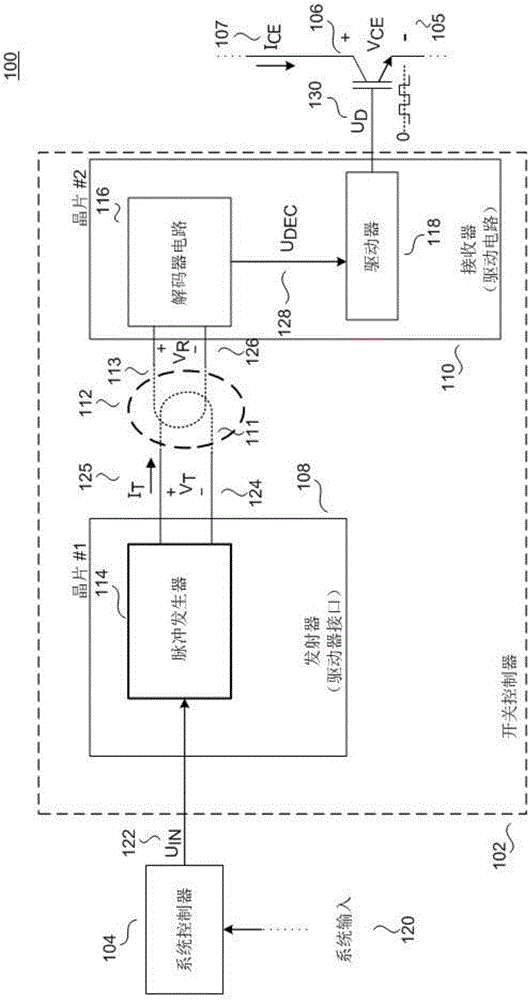

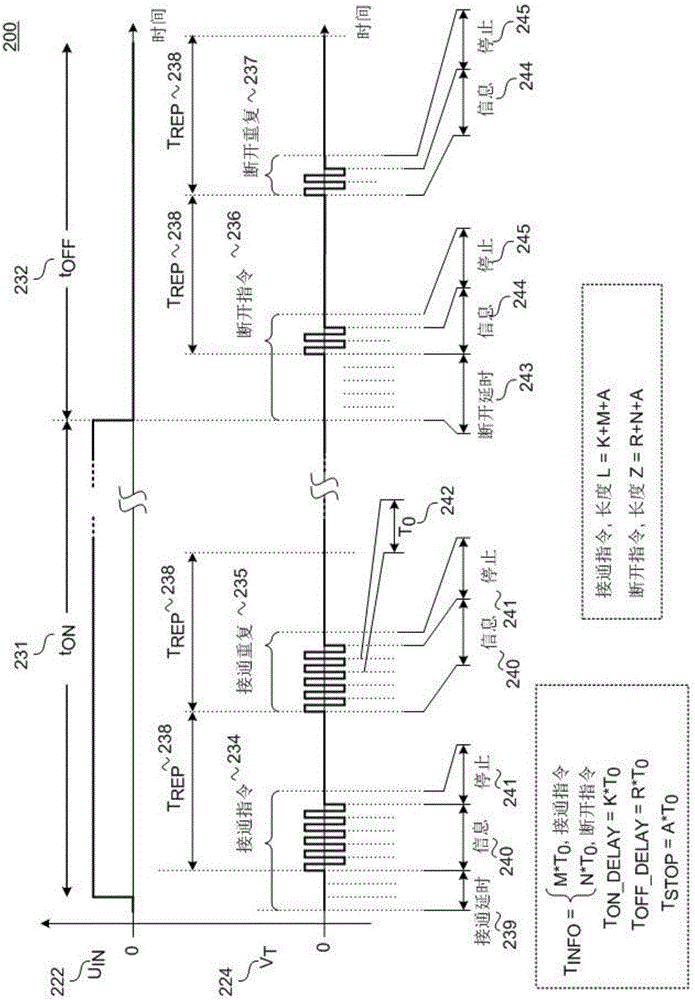

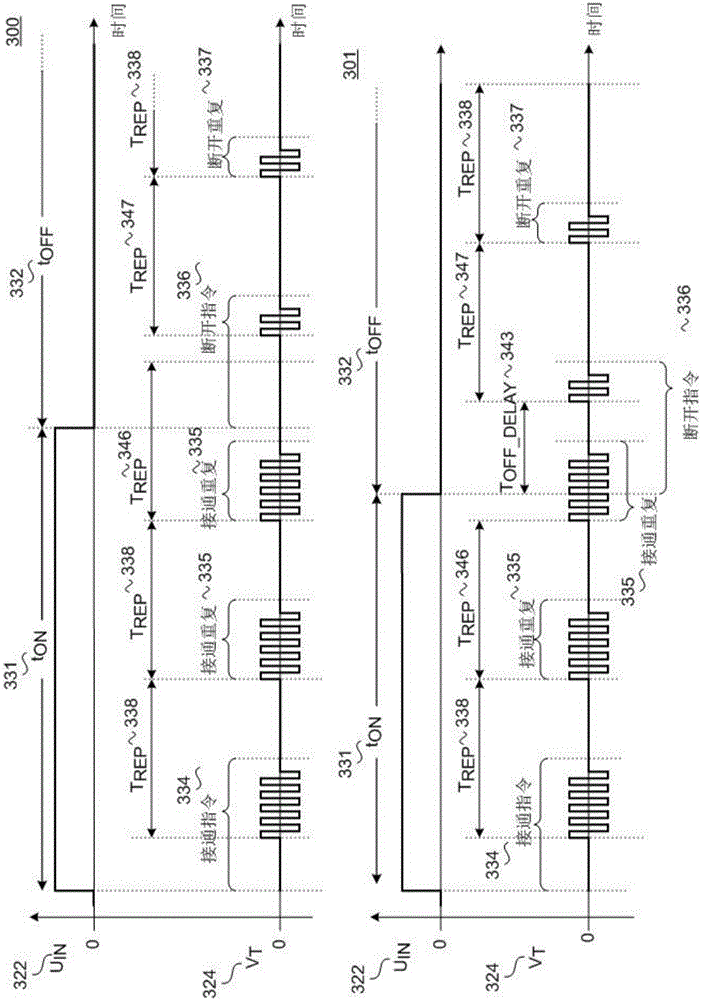

Communicating Across Galvanic Isolation, For Example, In A Power Converter

ActiveCN106341034AMultiple-port networksApparatus without intermediate ac conversionCouplingState representation

A signal transmission system for communicating across galvanic isolation. The signal transmission system includes first circuitry referenced 108 to a first potential, the first circuitry comprising signal transmission circuitry, second circuitry 110 referenced to a second potential and galvanically isolated from the first circuitry, the second circuitry comprising signal reception circuitry, and a magnetic coupling 112 between the first circuitry to the second circuitry across the galvanic isolation, the magnetic coupling comprising a transmitter-side inductor and a receiver-side inductor. The signal transmission circuitry can include a source coupled to output, to the transmitter-side inductor of the magnetic coupling, a first state representation that represents a first logic state with multiple transitions, the first state representation including at least a first upward transition, a first downward transition, a second upward transition, and a second downward transition.

Owner:POWER INTEGRATIONS SWITZERLAND

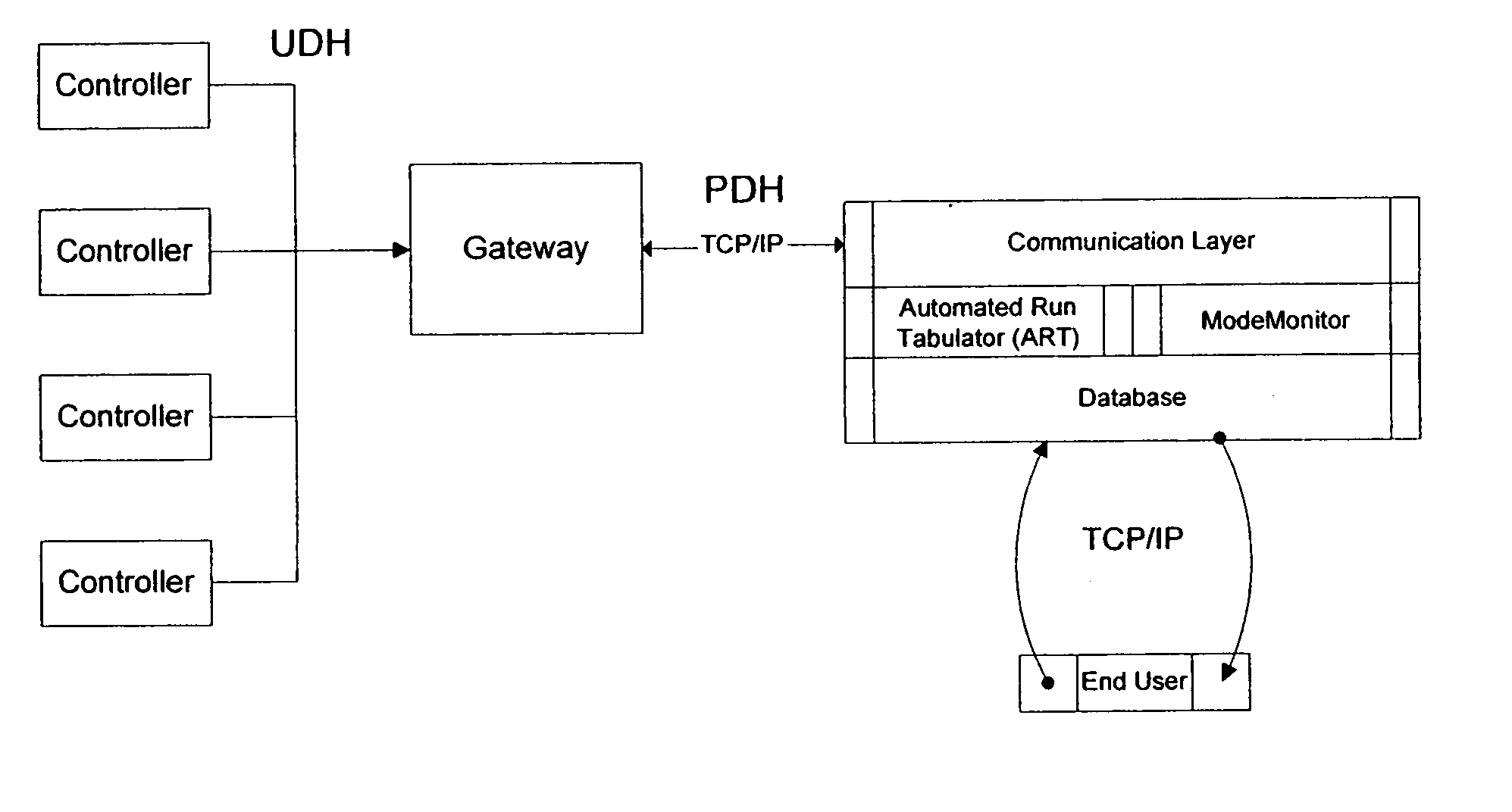

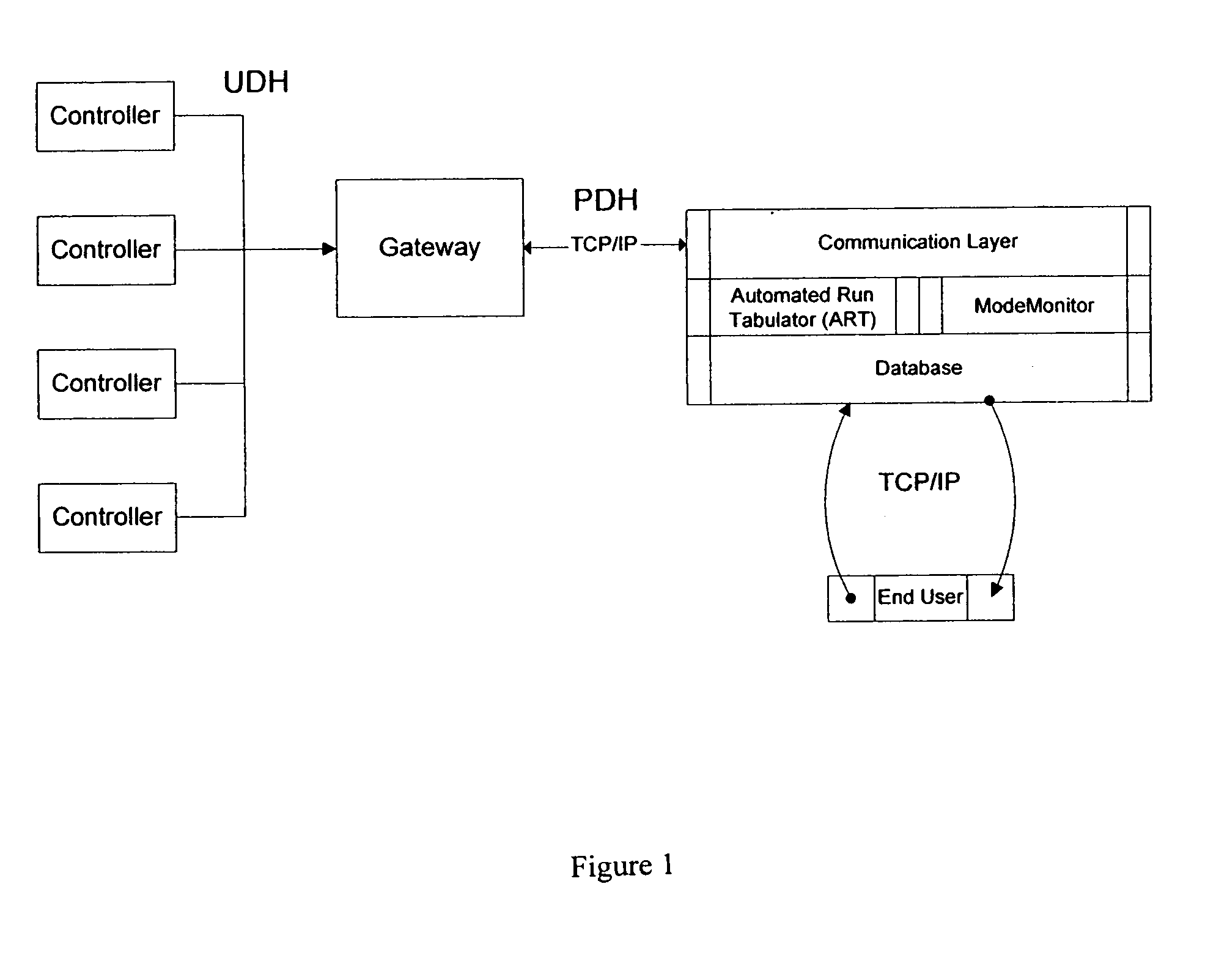

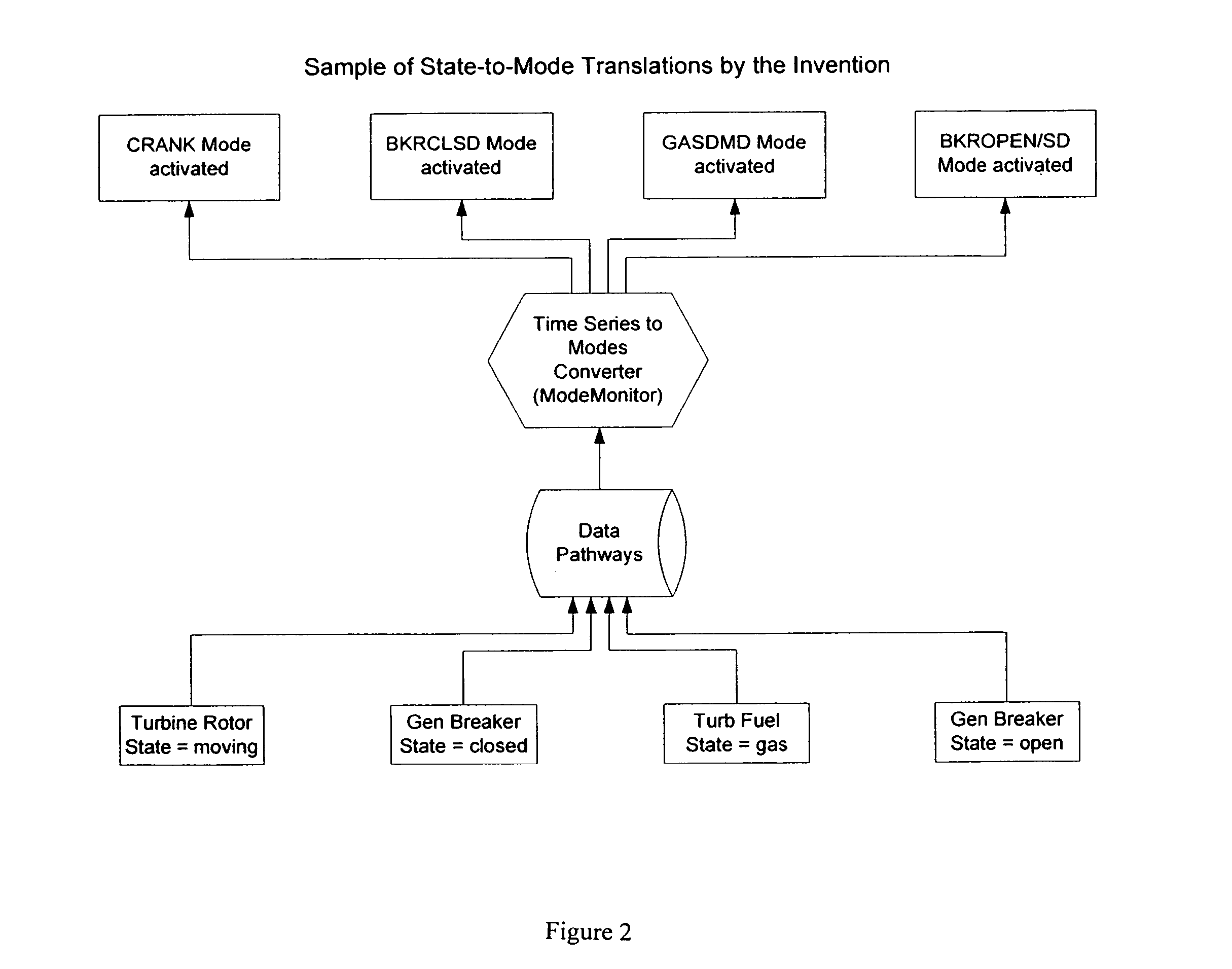

Analysis of time-series data from an electric power-producing asset for the inference of well-defined overlapping modes (ModeMonitor)

InactiveUS20050209799A1Maximal captureImprove reliabilityElectric devicesElectric testing/monitoringState representationTurbine

This invention relates to a maximization of the inferences which are derived from data involved in data processing representing asset modes based on applicable state representations. The maximization takes place using a single algorithm to automatically analyze information and infer from electric power turbine configurations.

Owner:LAURENT PATRYK A +2

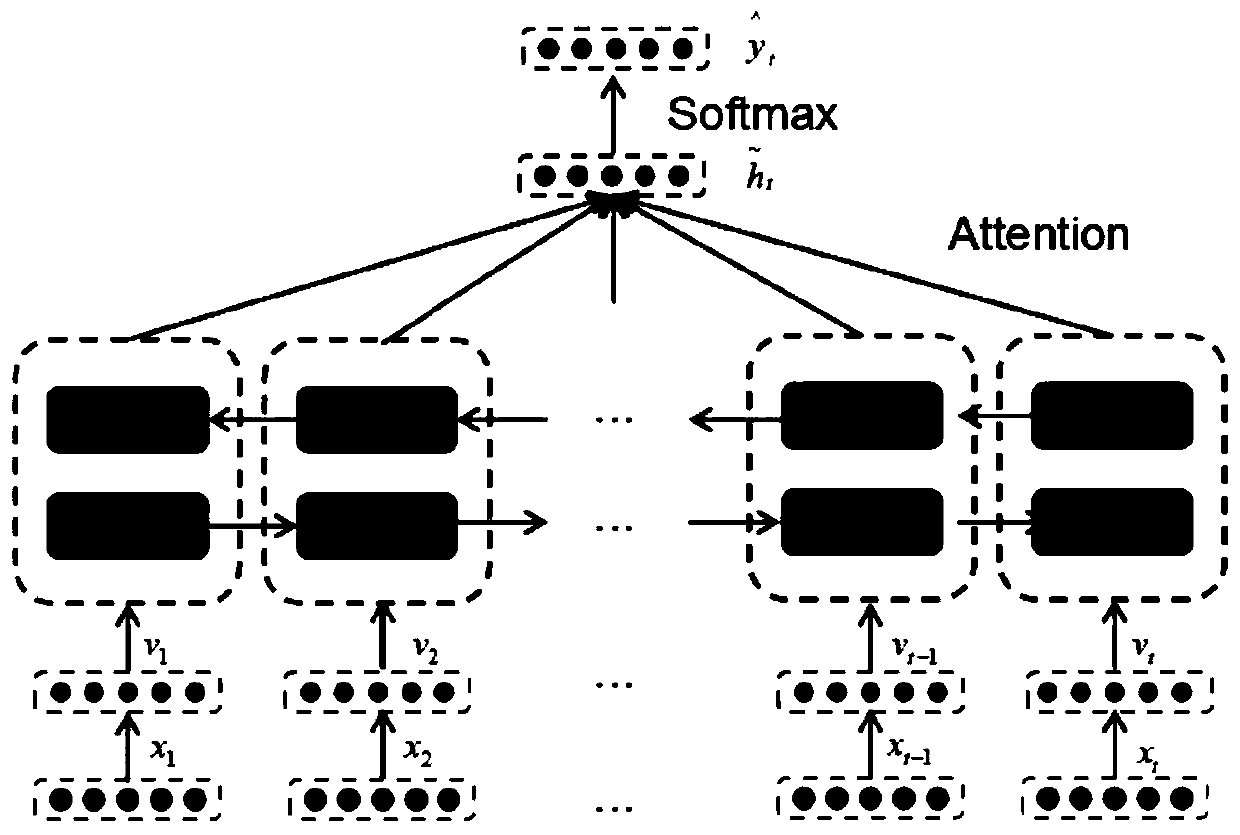

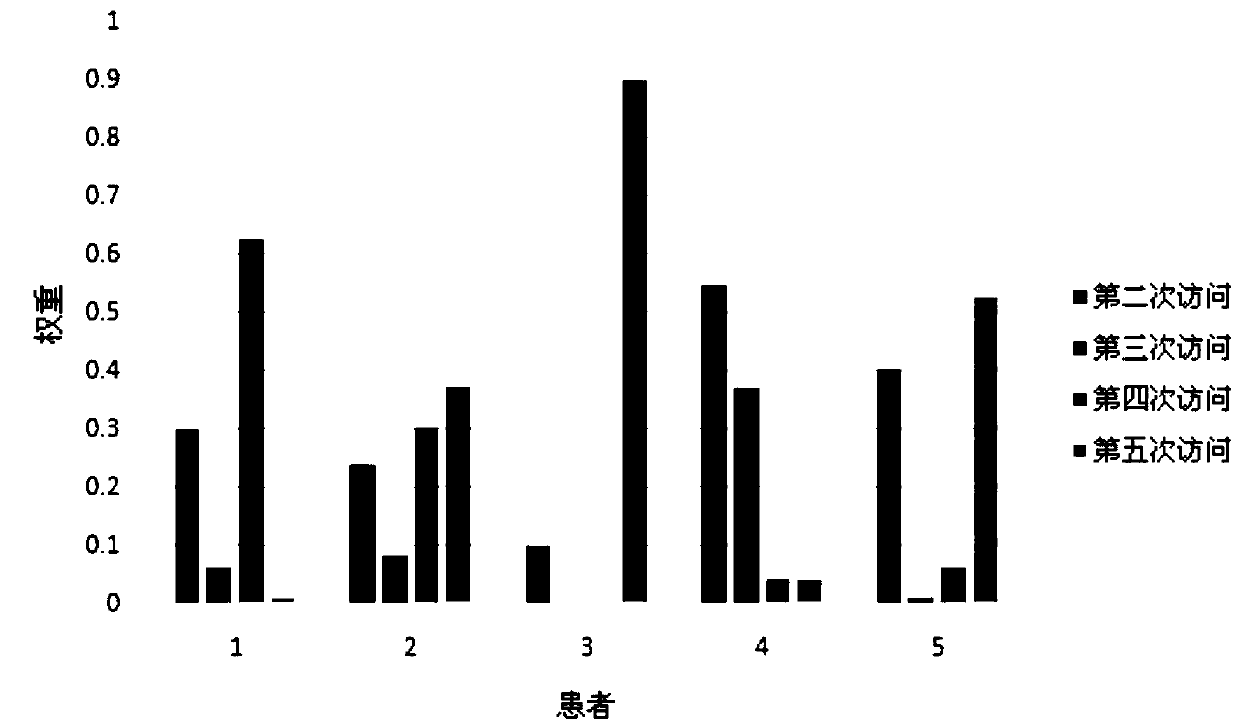

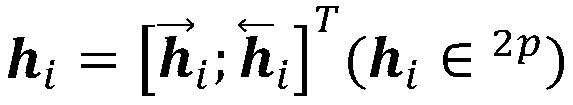

Diagnosis prediction method of bidirectional recurrent neural network based on attention

ActiveCN109887606AReasonably explain the prediction resultsMedical simulationMedical data miningClinical variablesState representation

The invention discloses a diagnosis prediction method of a bidirectional recurrent neural network based on attention, and relates to the technical field of prediction diagnosis. The diagnosis prediction method firstly embeds high-dimensional medical codes (ie, a clinical variable) into a low code layer space, and then inputs code representation into a bidirectional recurrent neural network based on attention to generate hidden state representation. The diagnosis prediction method inputs the hidden representation through a softmax layer so as to predict medical codes accessed in future. The experimental data shows that, by using the diagnosis prediction method of a bidirectional recurrent neural network based on attention, when predicting future access information, the attention mechanism can assign different weights to previous accesses, thus effectively completing the diagnosis and prediction task, and reasonably explaining the prediction result.

Owner:莫毓昌

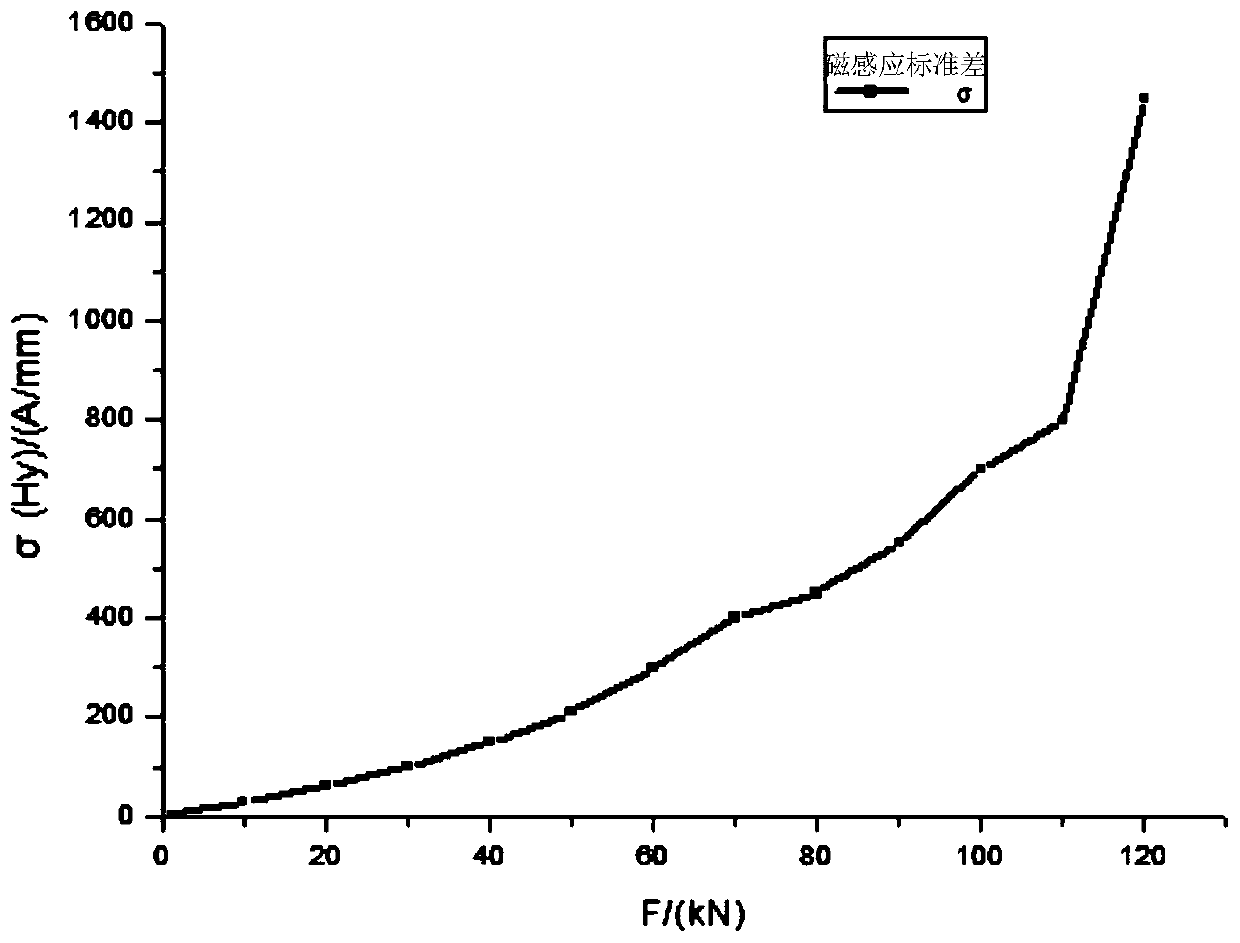

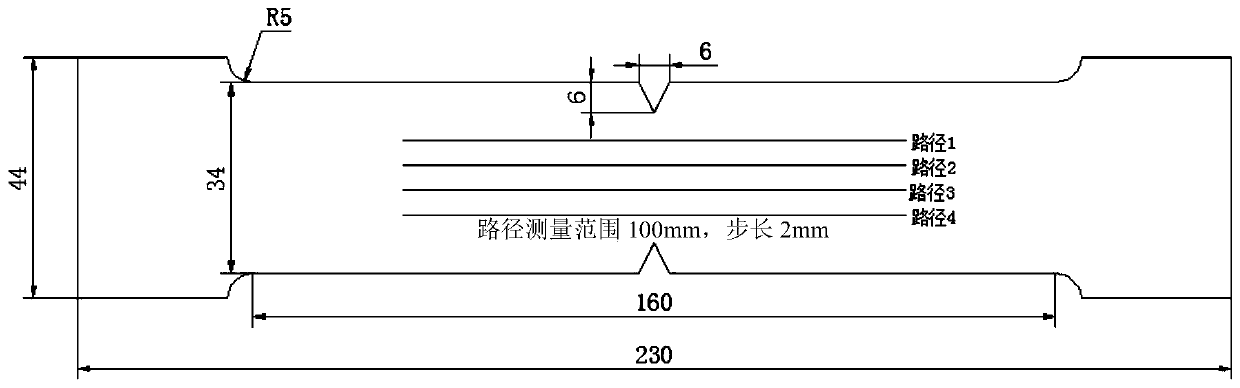

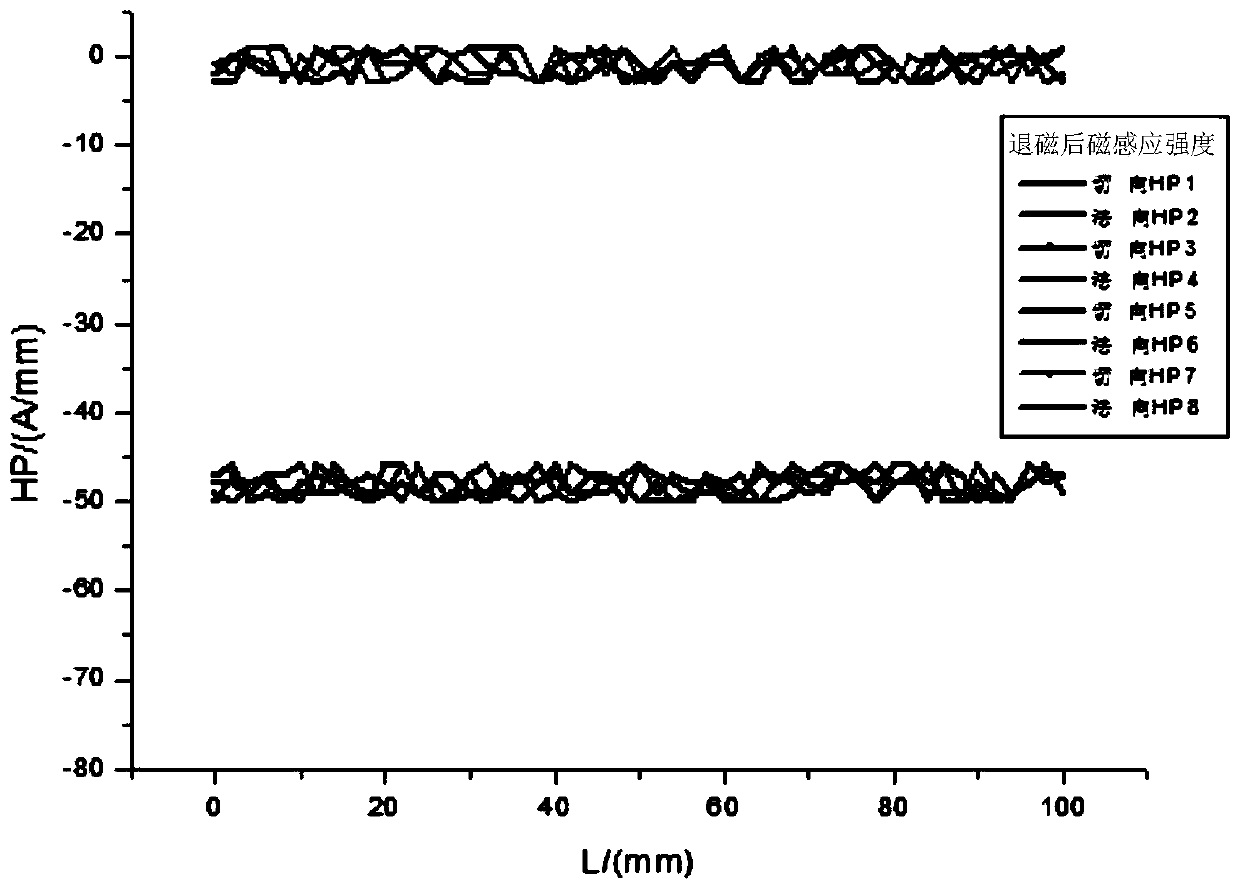

Evaluation method for early damage of additive manufacturing part based on metal magnetic memory detection

ActiveCN110308043ARealize non-destructive testingHigh discrimination accuracyMaterial strength using tensile/compressive forcesMaterial magnetic variablesMagnetic memoryState representation

The invention relates to an evaluation method for early damage of an additive manufacturing part based on metal magnetic memory detection and belongs to the field of metal magnetic memory detection innondestructive detection, wherein a mechanics theory and a force-magnetic coupling theory of ferromagnetic materials are used for guiding, and the variation condition of a residual magnetic inductionintensity standard deviation and a residual magnetic induction intensity gradient maximum value thereof along with the tensile load is used as an early damage state representation method of the additive manufacturing part. The residual magnetic induction intensity of the additive manufacturing part under different stretching states is detected by adopting a metal magnetic memory method, the earlydamage change process of the defect is characterized by the change of magnetic memory signals, and the residual magnetic induction intensity standard deviation and the residual magnetic field intensity gradient maximum value are used for representing the early damage situation of the additive manufacturing part. According to the method in the invention, the metal magnetic memory detection technology is combined with damage mechanics, the magneto-mechanical effect of the ferromagnetic additive manufacturing part is used to achieve nondestructive detection of the early damage of the ferromagnetic additive manufacturing part under the condition of not requiring magnetizing, and the judgment accuracy is high.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com