Multi-agent cooperative control system and method for process industry

A process industry and control method technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as obstacles to direct use, reduce collection and processing steps, strong robustness, and realize real-time dynamic optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

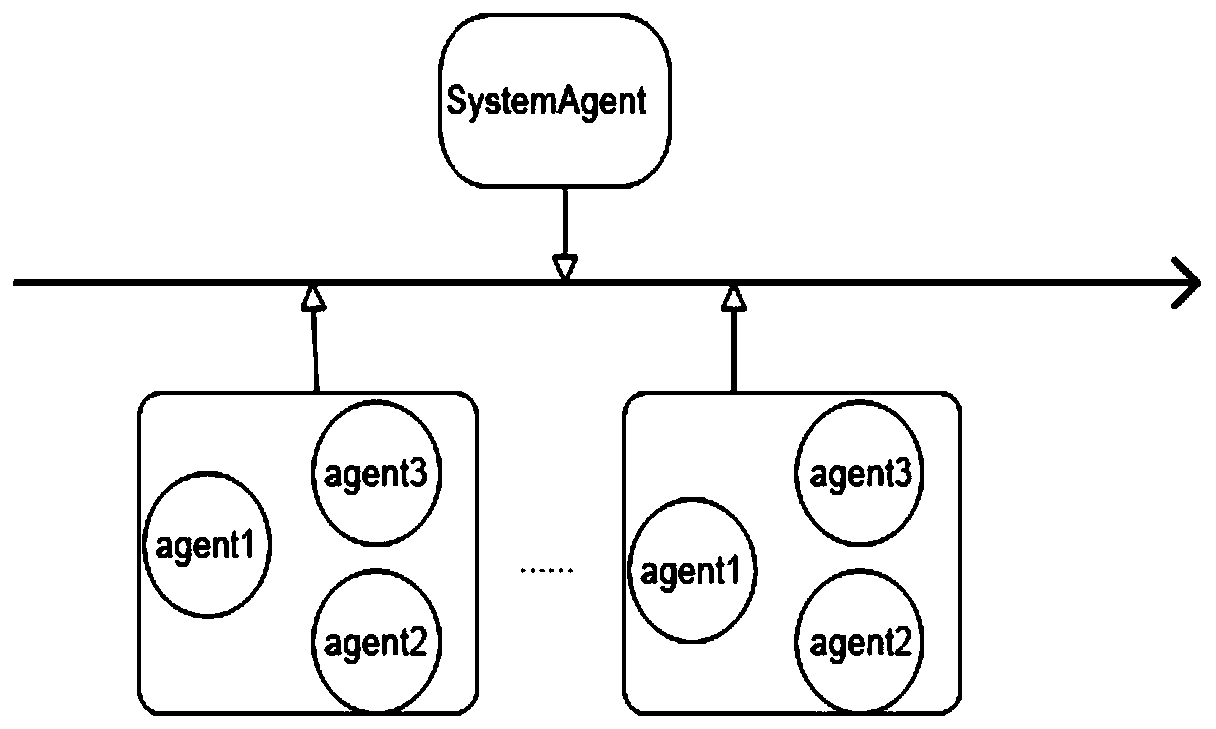

[0035] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a multi-agent cooperative control system for the process industry, including the system agent (SystemAgent) and agents in each production stage, each production stage is set with multiple agents that can communicate with each other and cooperate with each other, so The above-mentioned system agents and agents in each production stage are set in layers. The system agents are set on the upper layer for unified scheduling and task assignment of agents in each production stage; the agents in each production stage are set in the lower layer.

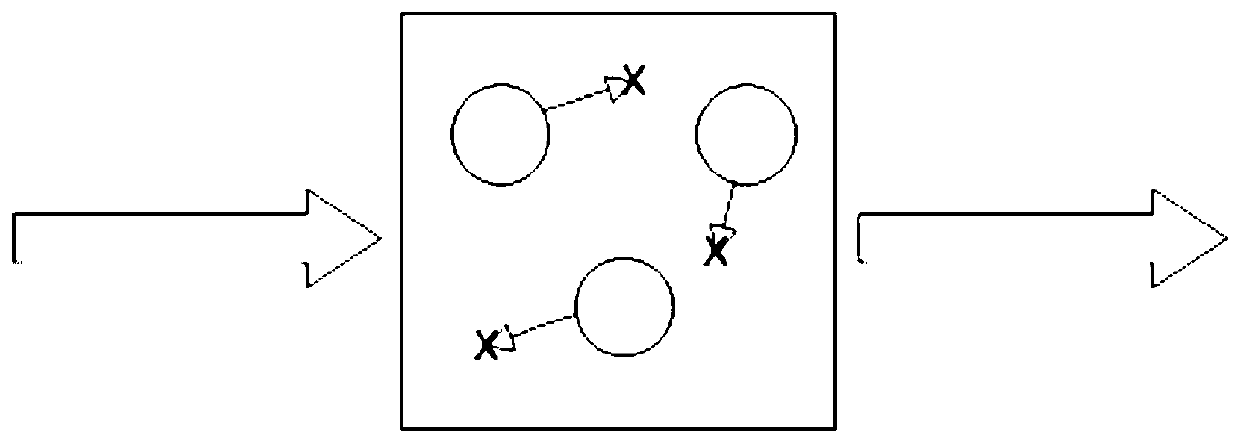

[0036] For example, the agent can be a robot in an unmanned production workshop. The multi-agent collaborative control system proposed in this embodiment is an intelligent collaborative control system oriented to the whole process, such as figure 1 with 2 As shown, it is composed of system Agent and Agent of each production stage. Each product...

Embodiment 2

[0074] This embodiment provides a multi-agent cooperative control system for the process industry, including the following modules:

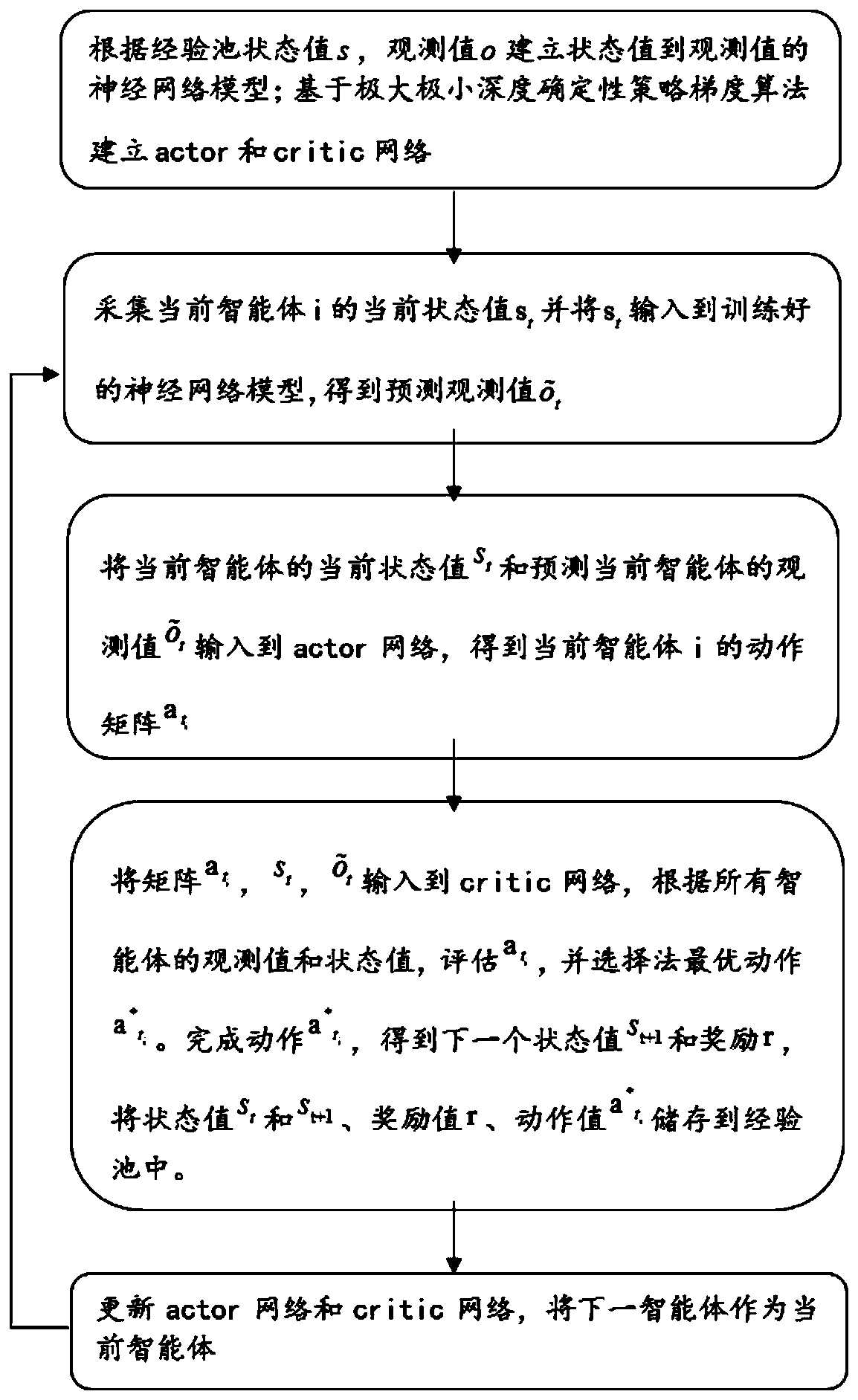

[0075] Model network building module: used to establish a neural network model from state value to observed value based on the real state value s and real observed value o of the experience pool; based on the max-min depth deterministic policy gradient algorithm, establish the actor network that outputs the initial policy and the critic network for judging feedback;

[0076] Observation value prediction module: used to collect the current state value s of the current agent i t , the current state value s t Input to the trained neural network model to obtain the current state value s t Corresponding to predict the observed value of the current agent

[0077] Initial policy output module: used to convert the current state value s of the current agent t and predict the observations of the current agent Input the actor network, and get the a...

Embodiment 3

[0080] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and run on the processor. When the computer instructions are executed by the processor, the steps described in Embodiment 1 are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com