Evaluation method for early damage of additive manufacturing part based on metal magnetic memory detection

A metal magnetic memory and additive manufacturing technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and analyzing materials, can solve the problems of early damage evaluation of parts that cannot be additively manufactured, and achieve accurate discrimination high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

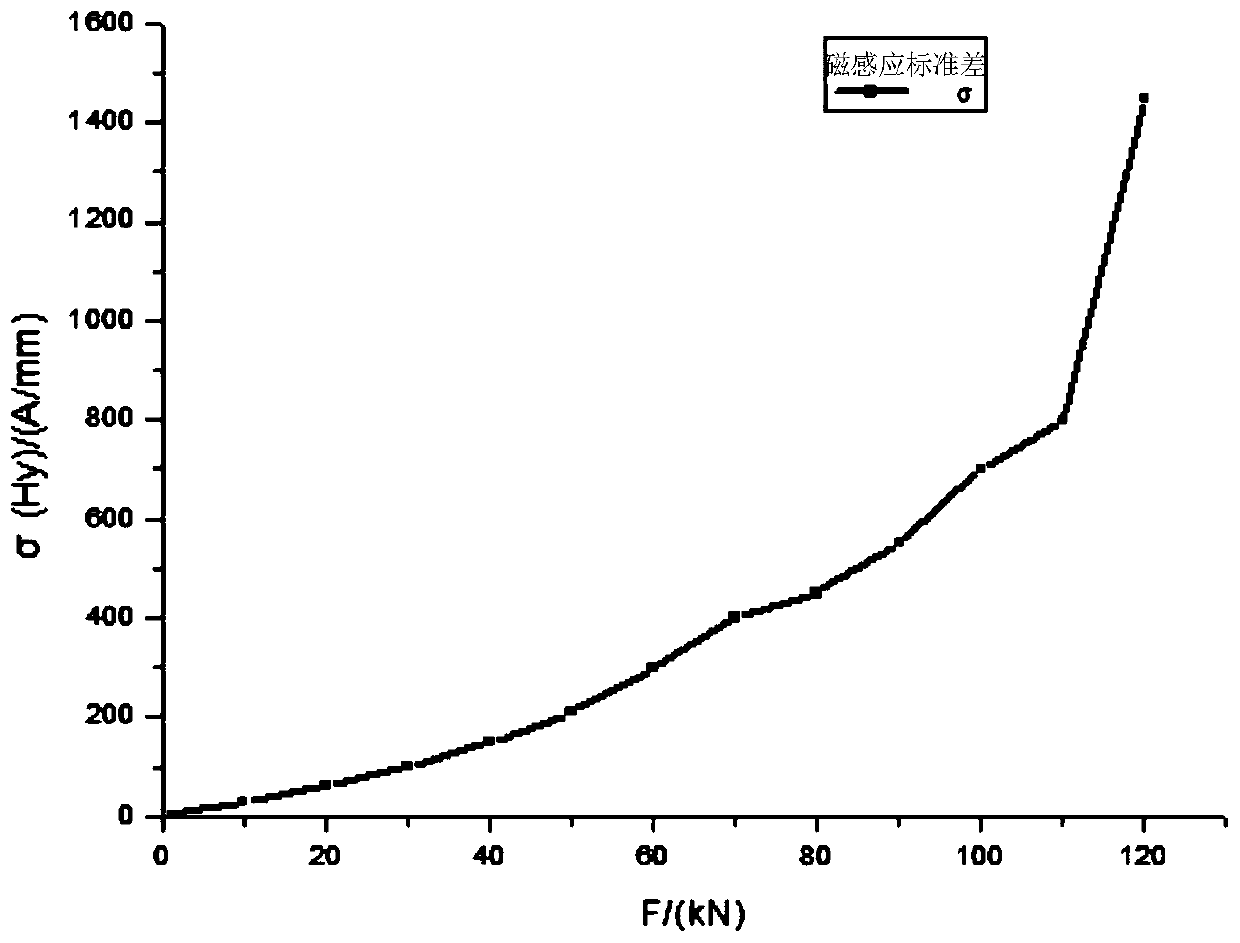

[0028] Embodiment: In this embodiment, the ferromagnetic additive manufacturing part with a V-shaped notch is taken as the research object, and different tensile loads are applied to it. After each loading, the surface magnetic memory signal is measured.

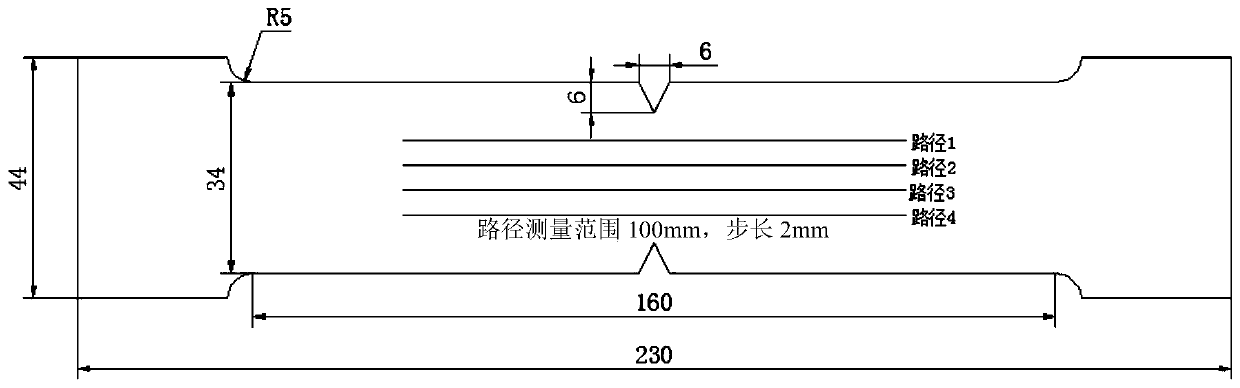

[0029] use as figure 2 The shown ferromagnetic additive manufacturing parts are samples used as embodiments, wherein each marked size (in mm) is as figure 2 shown.

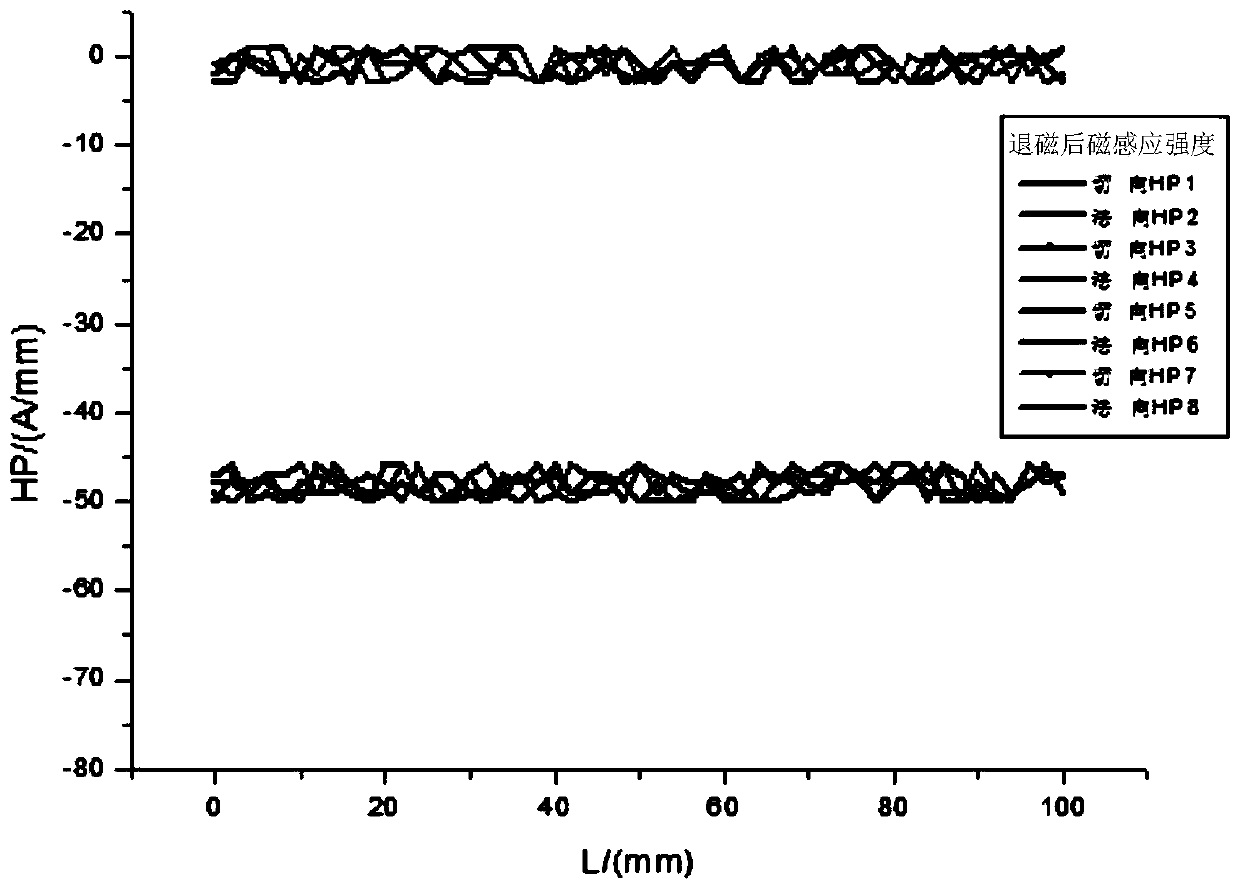

[0030] First place the workpiece horizontally on the test bench, demagnetize the workpiece, and then use the TSC-3M-12 stress concentration magnetic detector to measure the magnetic memory signal on the surface of the workpiece when it is not loaded along the detection path, and measure the initial magnetic memory. signal attached image 3 shown. The workpiece is clamped on the tensile testing machine, and the magnetic memory signal on the surface of the workpiece is measured again under the workpiece clamping state, which is convenient for comparison with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com