Ultrasonic 3D vibration and ELID (Electrolytic In-process Dressing) combined precision grinding system and method

A precision grinding and ultrasonic technology, applied in the field of precision manufacturing, can solve the problems that the grinding wheel cannot be trimmed on-line, the roughness value cannot be obtained efficiently, and the processing efficiency is low, so as to achieve simple manufacturing and assembly process, promote practical effect, and achieve grinding The effect of stable cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

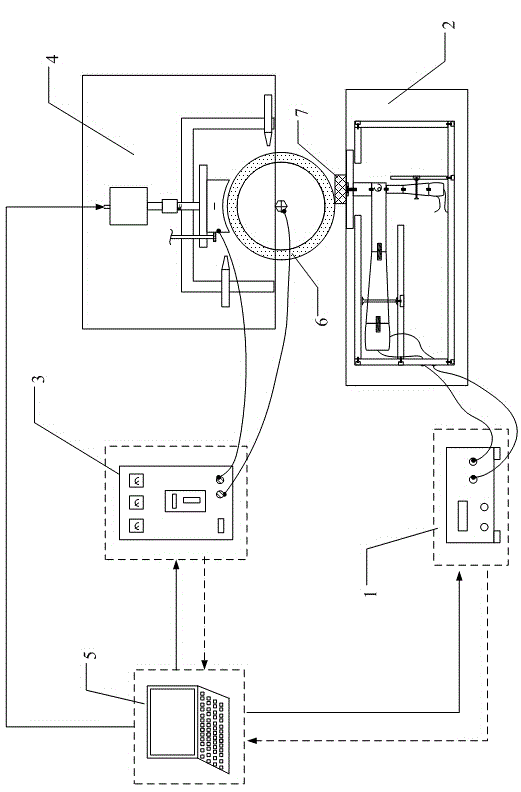

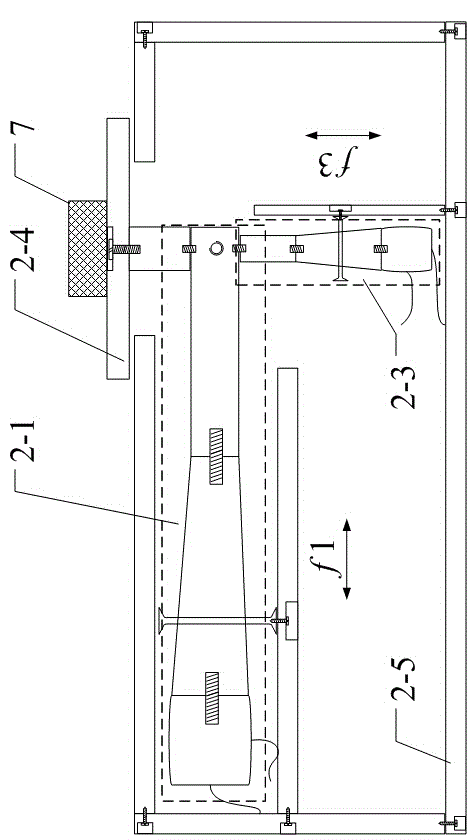

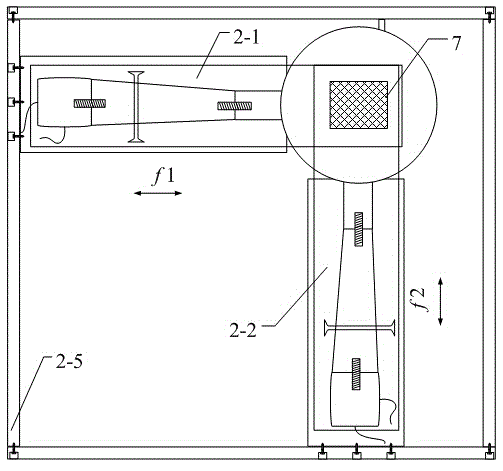

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6As shown, the ultrasonic 3D vibration compound ELID precision grinding system of the present invention includes a multi-channel ultrasonic generator 1, a 3D ultrasonic excitation table 2, a high-frequency DC pulse power supply 3, an automatic distance-adjustable electrode 4, a computer monitoring system 5 and a grinding wheel 6. The multi-channel ultrasonic generator 1 is connected to the 3D ultrasonic excitation table 2 through a cable; the workpiece 7 to be processed is fixed on the 3D ultrasonic excitation table 2 by mechanical clamping or gluing; the high-frequency DC pulse power supply The positive pole of 3 is connected to the grinding wheel 6, the negative pole of the high-frequency DC pulse power supply 3 is connected to the automatic distance-adjusting electrode 4; the computer monitoring system 5 is connected to the high-frequency DC pulse power supply 3, the automatic distance-ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com