Efficient filtering lower tube seat, fuel assembly and nuclear reactor

A high-efficiency filtration and fuel assembly technology, applied in nuclear engineering, nuclear power generation, nuclear power plants, etc., can solve problems such as suboptimal filtration performance improvement, weak filtration ability for short and small foreign objects, and difficult connection or welding. Flow performance, improved structural strength and reliability, and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

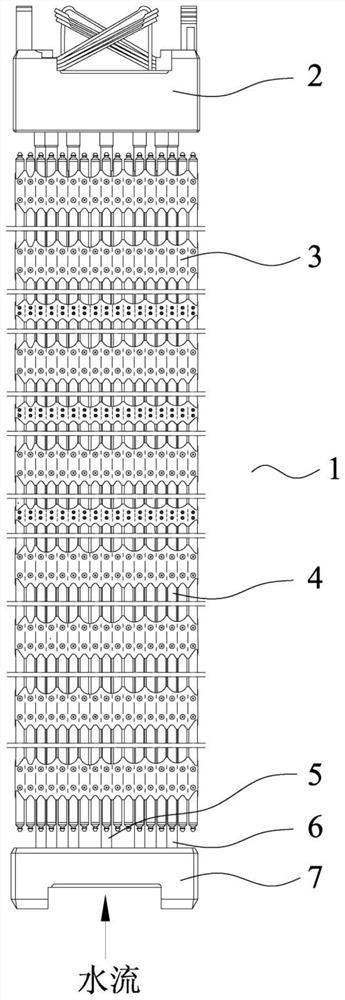

[0046] A nuclear reactor fuel assembly 1, comprising an upper tube base 2, a grid 3, a fuel rod 4, an instrument tube 5, a guide tube 6 and a lower tube base 7, such as figure 1 As shown, when the nuclear reactor is running, the coolant flows in from the lower tube base 7 and flows out from the upper tube base 2 .

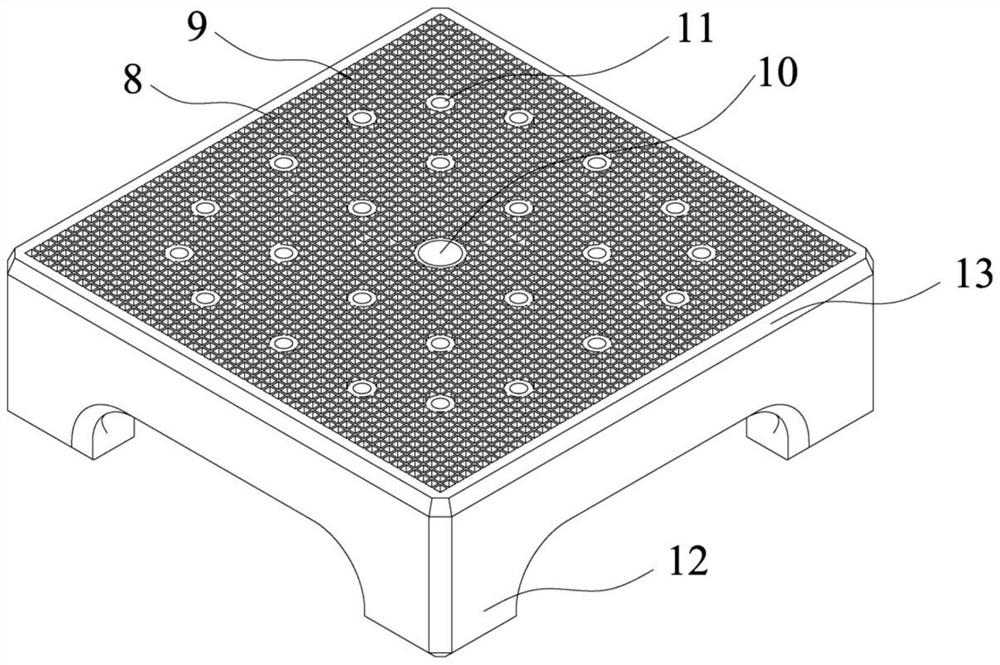

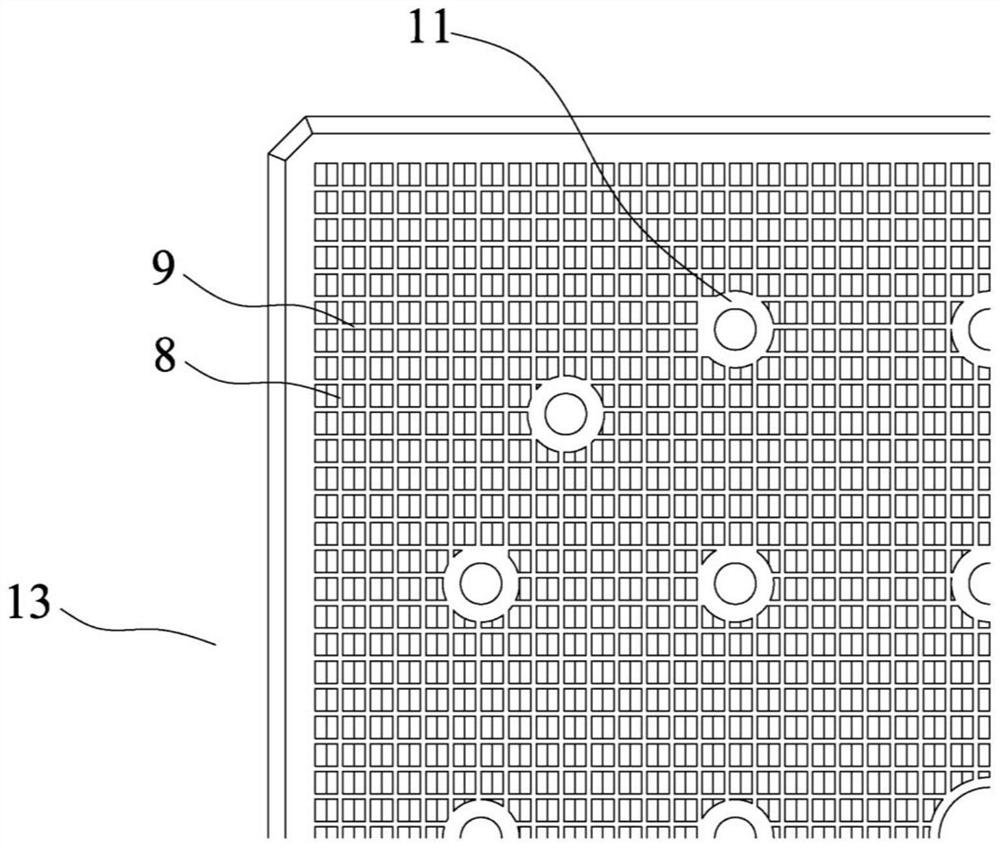

[0047] In order to solve the problems existing in the design and manufacture of the existing lower nozzle, this embodiment proposes a high-efficiency filter lower nozzle, specifically as Figure 2-3 As shown, the lower tube seat 7 of this embodiment is composed of a connecting plate 13 and a leg 12 . Wherein, the connection plate 13 of this embodiment is composed of S-shaped ribs 8, straight ribs 9, instrument tube support seat 10 and guide tube support seat 11, and the connection plate 13 of this embodiment is suitable for integral manufacturing.

[0048] Such as Figure 4As shown, the S-shaped ribs 8 of this embodiment are regularly and densely arranged at a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com