Battery cell, battery and preparation method thereof

A battery cell and tab technology, which is applied in the battery and its preparation, and the field of battery cells. It can solve the problems of low alignment accuracy, tight connection of reserved sub-tabs, and affecting the accuracy of the battery cell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

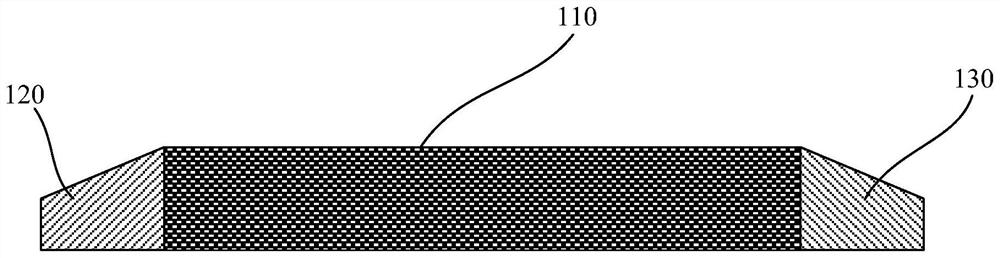

[0042] Further, the present invention also provides a method for preparing the above-mentioned electric core, which includes the following steps:

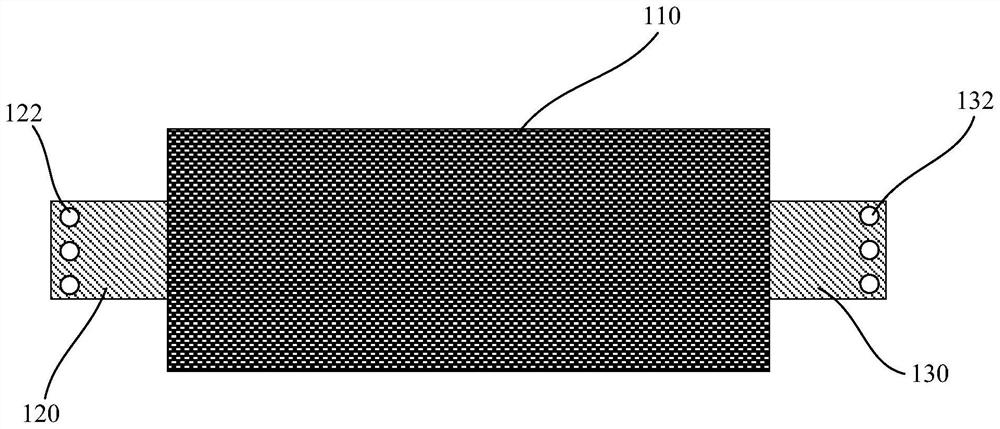

[0043] Each of the reserved positive pole ears is stacked to form a reserved positive pole ear, and each of the reserved negative pole ears is stacked to form a reserved negative pole ear. Prepare the positioning hole on the ear;

[0044] The positioning protrusions on the externally connected positive pole ear and the externally connected negative pole ear are completely inserted into the positioning holes on the reserved positive pole ear and the reserved negative pole ear, and respectively press the positioning protrusions, Each of the positioning protrusions is deformed so as to be snapped into the corresponding positioning holes.

[0045] In one specific example, when pressing each of the positioning protrusions, the pressure is 100kgf˜1000kgf.

[0046] In order to facilitate the understanding of the specific preparation pro...

Embodiment 1

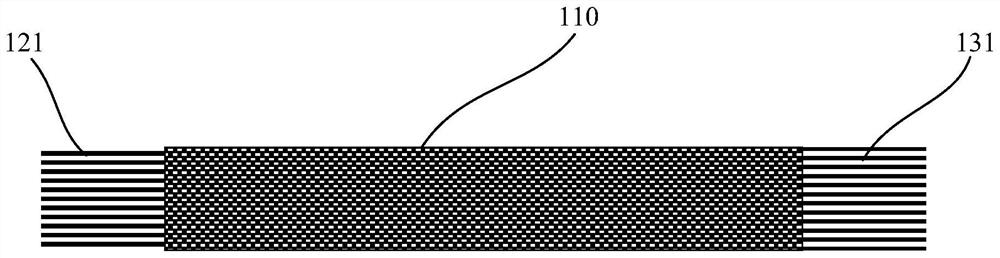

[0066] (1) A plurality of positive electrode sheets and a plurality of negative electrode sheets are stacked alternately in sequence, wherein the total number of positive electrode sheets is 30, and the total number of negative electrode sheets is 31.

[0067] (2) The reserved positive tabs connected to each positive electrode are laminated to form the reserved positive tabs, press to reduce the gap between the reserved positive tabs, and use a puncher to place the reserved positive tabs at the preset position Punch out three positioning holes that are arranged side by side and run through the reserved positive tabs; make the reserved negative tabs connected to the negative plates stacked to form the reserved negative tabs, and place the reserved negative tabs in the same way as above Positioning holes are prepared above; wherein, each positioning hole is a cylindrical hole, and the diameter of the circular bottom surface is 3 mm. After the punching is completed, cut the part ...

experiment example

[0074]According to the preparation method as in Example 1, 30 battery samples were prepared, and at the same time, 30 battery samples were prepared according to the preparation method of Comparative Example 1, and the positive tab or negative tab was reserved for random inspection, and the external electrodes of all the battery samples were uniformly tested. The distance d between the lower end of the short side of the ear and the electrode body, the specific results can be seen in Table 1.

[0075] Table 1

[0076]

[0077]

[0078] The distance d between the lower end of the short side of the external tab and the main body of the electrode can reflect the alignment accuracy of the external tab. Specifically, if the alignment accuracy of the external tab is high, the fluctuation of the distance d between the lower end of the short side and the main body of the electrode is smaller in multiple samples.

[0079] As the data shown in Table 1, for Example 1, the measured d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com