Custom implant fixture, method for manufacturing same, and custom implant system using same

A technology of a fixing device and a manufacturing method, which is applied in the direction of dental implants, dentistry, and dental prostheses, and can solve problems such as low alveolar bone depth, weak initial fixation force, and no connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The personalized and customized dental implant fixture and its manufacturing method of the present invention will be described in detail below with reference to the accompanying drawings.

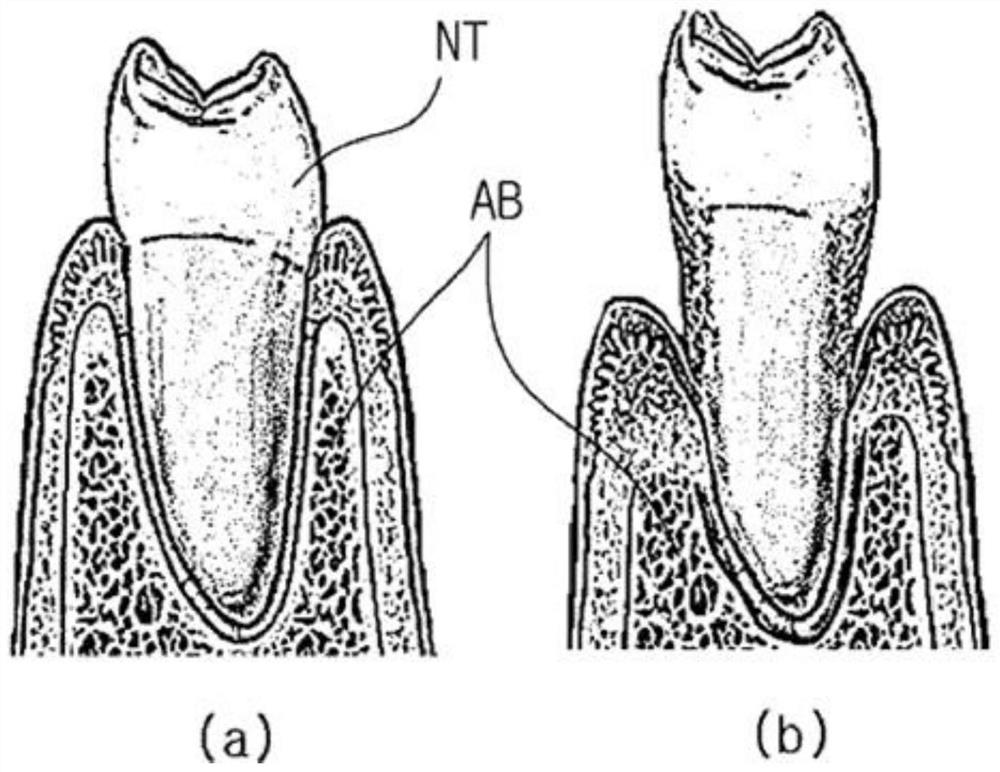

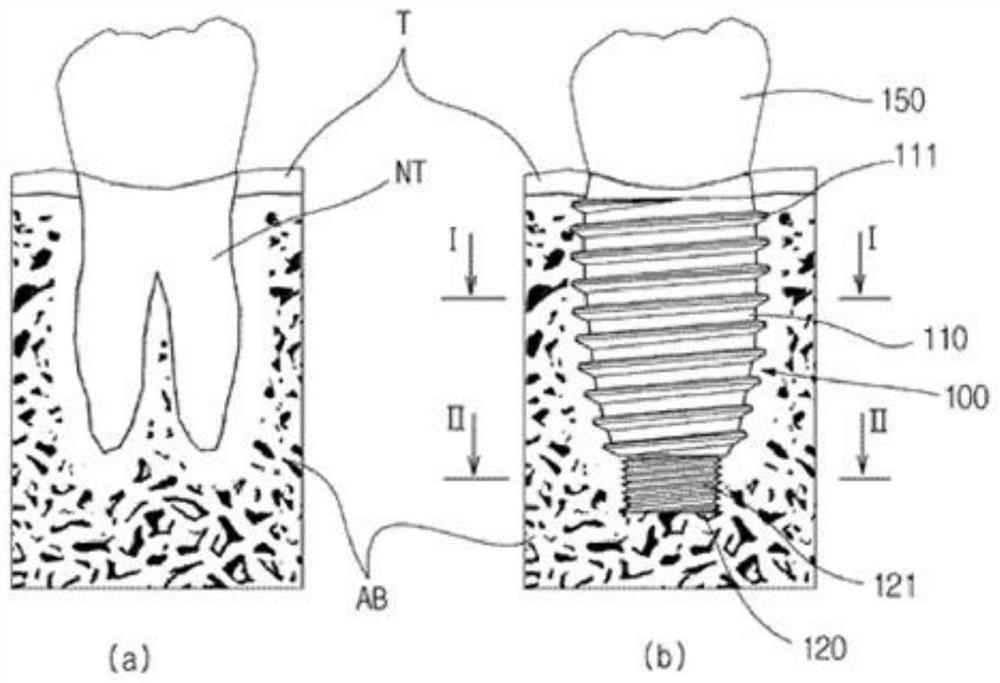

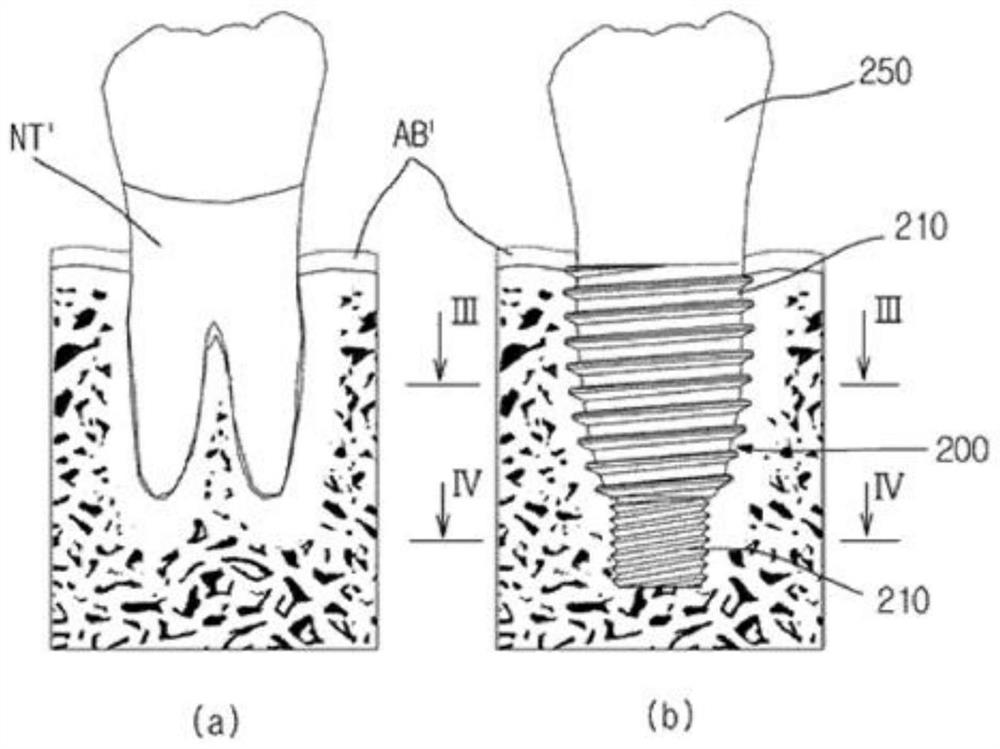

[0039] figure 1It is a graph comparing the case (a) of healthy teeth and the case (b) of teeth with periodontal disease according to the present invention. The case (b) of a patient with severe periodontitis is different from the case of healthy teeth (a) in that the height of the alveolar bone is low, and the alveolar bone AB surrounding the natural tooth NT is also in a weakened state. Even if the tooth is extracted in this state and an implant in the shape of the tooth NT is immediately implanted, the depth and area covering the tooth NT after tooth extraction are shallow and small, and it is difficult to ensure the initial fixation force of the implanted tooth. The personalized and customized dental implant fixture of the present invention provides an initial fixation force that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com